The engine in question has run for about 20 minutes and then I discovered the cases were cracked. Its an 1166 with G3 cams.

I have no experience with cam timing so I thought it would make sense to check the timing on the assembled engine as a form of practice.

i have a hot cam degree wheel kit with piston stops and dial indicator.

The degree wheel is mounted on the ignition end of the crank. As installed now the degree wheel is snug against the advance unit on my Dyna 2000 and I'm wondering if thats the way it should be mounted.

I used the piston stop to set the degree wheel at O Top Dead Center. I then rechecked using the piston stop and I'm an equal amount of 32 degree either side of top dead center

When I check the cam lobe centers on the intake I get 24.5 degrees at 40 ten thousands lift opening and 55 degrees at 40 ten thousands lift on closing.

24.5 + 55 + 180 = 259.5 259.5 / 2 = 129.75 129.75 - 24.5 = 104.25 which seems believable for intake setting although torque oriented .

On the exhaust cam I get 64 degrees at 40 ten thousands lift on opening and 14 degrees at 40 ten thousands on closing. The 64 is BBDc and the 14 is ATDC.

This results in 64 + 14 + 180 = 258 258/2= 129 129 - 14 = 115 for the exhaust. This number seems off to me.

I did find a reference to ignition advance affecting cam lobe numbers. The reference was with respect to cars but got me wondering. Th..e reference said 6 degrees of advance would lead to 104 and 114.

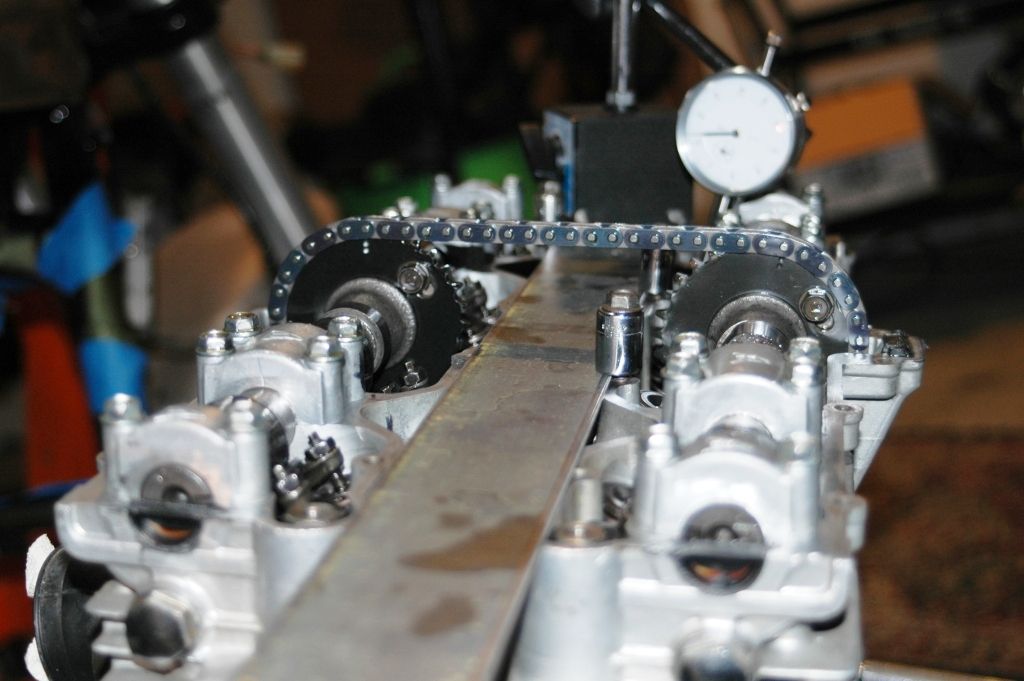

The cams are mounted with slotted sprockets and the the cam chain appears to be at 21 pins counting from the marks on the sprockets.

So should I remove the dyna plate and advance unit from behind the degree wheel or does it not make any difference. Just doesn't seem right that the buler would choose 104 /114 for a GS1166. I was expecting numbers in the 106 /108 range.

.png)

Comment