Well done, the plates look excellent.

Announcement

Collapse

No announcement yet.

1984 Katana 7/11

Collapse

X

-

Looking great, i am always amazed what you are able to achieve with basic tools. No laser cutting, lathes and mills.

Well done, the plates look excellent.Current Bikes.... 81,1230Kat, 86,GSXR1100, 86,RG500,

The 80`s - Back in the days when men looked like women, women dressed like whores and the music F@#KING ROCKED!

-

Cheers mate! Although there will be a mill involved soon... a mate has offered the use of the milling attachment on his lathe to use to recess the bolt holes in the anti-dive plates so they're a bit neater.

Gotta say I like your signature! Got a pic of that Kat?

1982 GS450E - The Wee Beastie

Got a pic of that Kat?

1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

-

I had a trip down to a mate's place during the week where we got some milling done, and then during the weekend I finished them up with a little more filing and sanding then a run on the cutting and buffing wheels.

7858992F-23F7-4699-A128-E8CCB9CAA5FF by starpoint73, on Flickr

7858992F-23F7-4699-A128-E8CCB9CAA5FF by starpoint73, on Flickr

B8A84917-1925-4CB2-B54F-6D6535055747 by starpoint73, on Flickr

B8A84917-1925-4CB2-B54F-6D6535055747 by starpoint73, on Flickr

He also kindly provided an offcut of pig skin gasket material which I cut two gaskets from.

AEBDB860-07A6-4899-8AA5-75BBBEB3DC1E by starpoint73, on Flickr

AEBDB860-07A6-4899-8AA5-75BBBEB3DC1E by starpoint73, on Flickr

Then I applied some blue loctite and bolted them in place followed up by a quick once over with the Mothers polish.

3FC6DDAC-E13D-47AE-939D-0086144E8F42 by starpoint73, on Flickr

3FC6DDAC-E13D-47AE-939D-0086144E8F42 by starpoint73, on Flickr

447FB6BA-5618-4951-8D40-23CC3154C446 by starpoint73, on Flickr

447FB6BA-5618-4951-8D40-23CC3154C446 by starpoint73, on Flickr

83618F11-296F-4B67-8188-0F2BA8F958F6 by starpoint73, on Flickr

83618F11-296F-4B67-8188-0F2BA8F958F6 by starpoint73, on Flickr

I got the right preload adjuster cleaned up so it moves properly now into all four positions and got everything ready to assemble.

D2431909-1E55-4B3C-A000-2335D6F009C4 by starpoint73, on Flickr

D2431909-1E55-4B3C-A000-2335D6F009C4 by starpoint73, on Flickr

DF9903EC-3F9A-4042-881D-DB3CB6F124FD by starpoint73, on Flickr

DF9903EC-3F9A-4042-881D-DB3CB6F124FD by starpoint73, on Flickr

Then I realised... can't use a big socket to drift the fork seal into place because the damper rod and stanchion go in first.

What trick do you guys use to get these in safely? That's the only thing holding me up now...

2097EA5C-56CD-47E4-8D41-BC76692367C7 by starpoint73, on Flickr

Last edited by pete; 07-03-2017, 04:03 PM.1982 GS450E - The Wee Beastie

2097EA5C-56CD-47E4-8D41-BC76692367C7 by starpoint73, on Flickr

Last edited by pete; 07-03-2017, 04:03 PM.1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

-

I found a piece of PVC pipe the exact right size for the fork seals and the copper washers for the damper rod bolts showed up during the week so I was able to finish the forks off yesterday.

Pretty happy with the end result, nice and clean and tidy.

3DC0A0F3-F8B6-419B-8AF2-31A1BE58D380 by starpoint73, on Flickr

3DC0A0F3-F8B6-419B-8AF2-31A1BE58D380 by starpoint73, on Flickr

And I remembered to the do the fork caps as well.

C9A130E6-135C-4828-9BB4-F5952A39170E by starpoint73, on Flickr

C9A130E6-135C-4828-9BB4-F5952A39170E by starpoint73, on Flickr

I spent a while on the shock mount bushes on the swingarm but no matter what I did they would'nt budge at all.

I soaked them in Inox then found a pretty perfectly sized socket with a large one for the back side.

I tried both the bench vise and bolt through the middle methods, and all I managed to do was break the bolt and bend the bench vise arm with the breaker bar.

As the bushes are rubber I wasn't game to try heat, so I think my only choice at this point is to cut the rubber to get the inner metal ring out, then carefully cut the outer metal ring to allow it to shrink a bit and release. Not pretty but I'm out of ideas on any other way at the moment.

Once I get those sorted I want to assemble the basic roller again and use a pro-tip I got and use a spirit level to confirm my frame/forks/swingarm are all pretty straight.Last edited by pete; 07-03-2017, 04:05 PM.1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

-

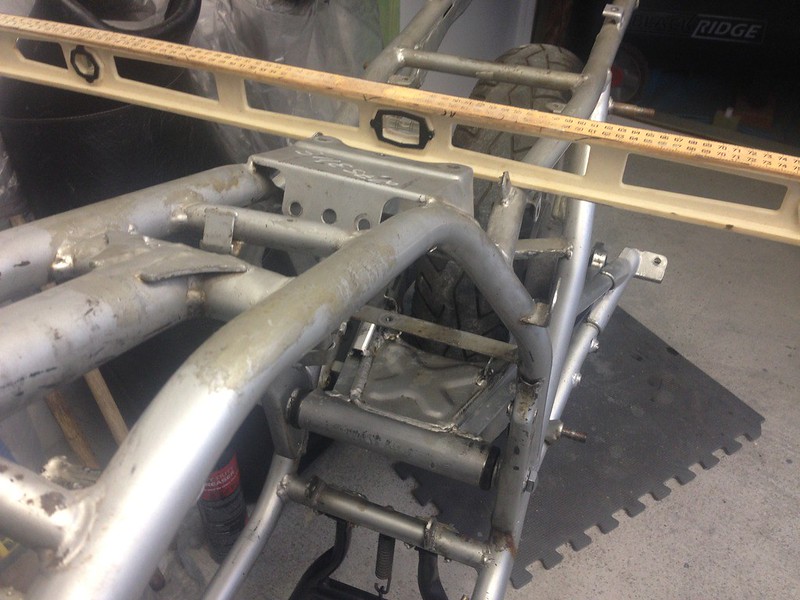

I had three things I wanted to achieve yesterday... get some parts so I can make a press for the shocky bushes in the swingarm, get the basic roller put together so I can do the quick and dirty check for straightness, and clean the wheels up so I can see if I need to paint them or not.

I assembled the basic roller... if only that frame was powder coated and this was final assembly...

Made sure it was on a level part of the shed floor then started moving the spirit level around the frame, and all good. I didn't notice a difference at any point from front to back or across the swingarm.

I also checked the front and rear tyres vertically and they were good too, so I'm pretty happy I don't need to worry any more about that.

I know it doesn't check front to rear alignment and while I didn't string line it, line of sight definitely shows the front/rear tyres aligned which is enough for me to proceed.

DE4682A2-014C-4F80-965B-B03197BF7DA2 by starpoint73, on Flickr

DE4682A2-014C-4F80-965B-B03197BF7DA2 by starpoint73, on Flickr

8FEC25C5-5D86-4674-B9BB-A2B857457B49 by starpoint73, on Flickr

8FEC25C5-5D86-4674-B9BB-A2B857457B49 by starpoint73, on Flickr

0729E797-DCF0-488E-819D-0390FC0EA2D6 by starpoint73, on Flickr

0729E797-DCF0-488E-819D-0390FC0EA2D6 by starpoint73, on Flickr

Then I managed to get some steel, threaded rod, etc. to make the press, but got back too late to break out the angle grinder to start cutting, but at least I have the parts and a plan now.

I still did manage to get the wheels out and give them a good soak in degreaser and a rub down with a scrubbing brush. They're not perfect but they'll work as is for what I want. At least if I change my mind down the track they can pretty easily be removed and painted later.

9143E7D5-6C58-4BD0-B036-C505C76EE14C by starpoint73, on Flickr

Last edited by pete; 07-04-2017, 03:47 PM.1982 GS450E - The Wee Beastie

9143E7D5-6C58-4BD0-B036-C505C76EE14C by starpoint73, on Flickr

Last edited by pete; 07-04-2017, 03:47 PM.1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

-

After losing last Sunday to work, I finally got to finish my press off to a useable state yesterday.

It's not the prettiest thing in the world but it seems to be useable and functional which is all that matters.

The only suitable steel I could find was two U sections welded together back to back to form a H section, so I had to tack some plates on to give a flat surface to press on.

I tacked some nuts on the back of the plates so I could bolt down the sockets to keep them in place also.

The only suitable thing I could find handy was some timber to somewhat clamp the jack in place, just mainly to stop it moving around.

Hopefully I can use this as somewhat of a metal brake for next time I need to bend some sheet steel or aluminium too.

7A8EAD0B-315A-4382-B4D7-6300617F2BD5 by starpoint73, on Flickr

7A8EAD0B-315A-4382-B4D7-6300617F2BD5 by starpoint73, on Flickr

I still had to apply heat to the swingarm but getting the bushings out wasn't that big a deal once I was able to use the press.

180D2250-86C5-4218-989A-91276D047BA6 by starpoint73, on Flickr

180D2250-86C5-4218-989A-91276D047BA6 by starpoint73, on Flickr

Getting the new ones in was even easier after 30 minutes in the freezer and then using the press again.

A66A2D70-F762-4E0E-B0FE-11C820D96AA7 by starpoint73, on Flickr

Last edited by pete; 07-04-2017, 03:50 PM.1982 GS450E - The Wee Beastie

A66A2D70-F762-4E0E-B0FE-11C820D96AA7 by starpoint73, on Flickr

Last edited by pete; 07-04-2017, 03:50 PM.1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

-

Ducked over to see a man about a horse last night... came back with starter clutch, stator, rotor, etc.

33B1F0B4-9C70-413C-99D7-EC42FAC41AF4 by starpoint73, on Flickr

Last edited by pete; 07-05-2017, 04:28 PM.1982 GS450E - The Wee Beastie

33B1F0B4-9C70-413C-99D7-EC42FAC41AF4 by starpoint73, on Flickr

Last edited by pete; 07-05-2017, 04:28 PM.1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

-

Looks like I'm ending up with Flickr rather than Mediafire for my photo hosting... gonna be some time before I go back and fix the thread but at least new stuff will be good.

I'm hoping to get some time off work late in July, so it's time to finalise prep to get the frame and other bits powder coated.

I smoothed off the 7/11 engine mounts yesterday and realised I still need to get one shock spring back off again.

I'm really not happy with my original shock spring compressor so I hacked it up and made a new one which is a lot easier to use.

The long bolt runs through the clevis mount and the hooks simply pull the spring down away from the locking ring, very simple.

Then I decided to fix the front chain guard mount on the swingarm which involved aluminium welding.

All things considered it didn't turn out as ugly as I expected and it seems to be nice and firm on there, obviously I need a much shorter bolt and it needs a lot more cleaning up yet.

1982 GS450E - The Wee Beastie

1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

-

I finally spent some time last night mocking up the colour scheme. I'm not good at this, but a little imagination should give you an idea... the engine will be black is the main difference and this is a photo I found on the interwebs, so the red on the frame isn't quite right compared with the seat colour.

Mock Up 1 by starpoint73, on Flickr

1982 GS450E - The Wee Beastie

Mock Up 1 by starpoint73, on Flickr

1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

-

Cheers BigD! I'll have to check it out, must've missed that one... and yep, moved to Flickr as I discovered I already had an account there so it's nice and easy.1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

-

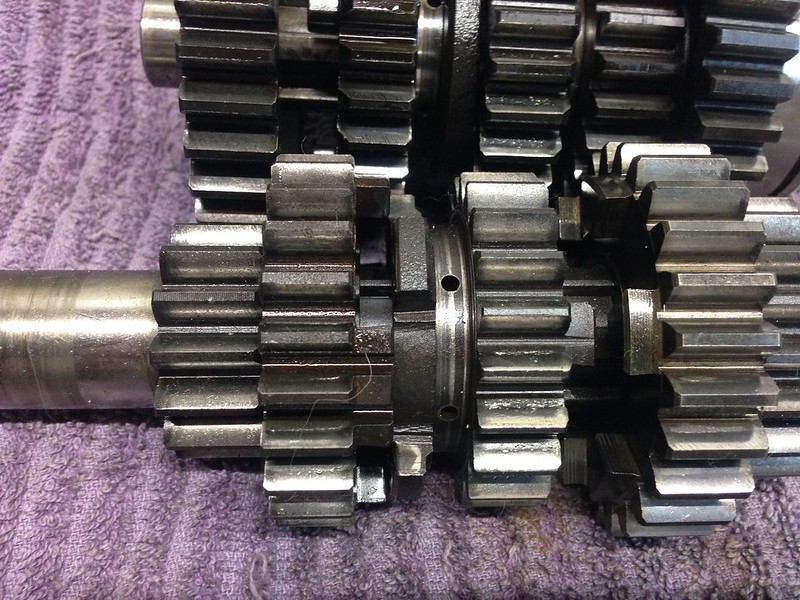

I went for a bit of a ride yesterday to pick up another gearbox.

It's supposed to be from a low km Kat motor but I suspect it's more like 120k rather than the 20k he mentioned as 5th has some issues.

The rest of it is much better than what I have though and I'm tempted to just use it as is and just replace the bearings.

It's on the left.

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

You can see what 5th is like:

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

3rd and 4th are screwed on mine and it looks to me like 5th is close to going too:

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Worst case is I can get one good gearbox out of the two and then have some spare gears and shafts as all the shafts themselves look to be pretty good.

I just need to drop them into the top case yet to check the lash out.1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

-

I need to make a key decision this weekend... the colour of the powder coating.

I have to choose from the 6500+ colours available from Prismatic Powders which is quite the challenge, however I've managed to narrow it down to two.

Astatic Red PSS-1738 or Bright Red PSB-6401.

Astatic is listed as a deep cherry red, whereas Bright is listed as a solid bright red/orange tone, and to be honest that describes what I think of as my seat colour.

The issue I'm having is I can only find one photo on the net of Bright Red, whereas there are heaps of Astatic Red ones out there. I still reckon Bright Red is right but if anyone's keen to offer an opinion.

It's really hard to judge based on photos with different lighting etc.

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Here's the one and only Bright Red image I can find:

And Astatic Red:

1982 GS450E - The Wee Beastie

1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

-

Cheers Steve! Yeah I'm stoked with the job the upholsterer did on the seat, top notch job and the very brief sit down I've had on it tells me it's gonna be a comfy ride too.

I asked my wife to have a look today as she has a much better eye for colour than I do, and she's thinking Astatic Red... so I did a comparison pic up and I'm thinking she's right... left to right in the middle row is Really Red, Bright Red, then Astatic Red...

Comparison by starpoint73, on Flickr

1982 GS450E - The Wee Beastie

Comparison by starpoint73, on Flickr

1982 GS450E - The Wee Beastie

1984 GSX750S Katana 7/11 - Kit Kat - BOTM May 2020

sigpic

450 Refresh thread: https://www.thegsresources.com/_foru...-GS450-Refresh

Katana 7/11 thread: http://www.thegsresources.com/_forum...84-Katana-7-11

Comment

.png)

Comment