Announcement

Collapse

No announcement yet.

Hillbilly Valve Spring Compressor

Collapse

X

-

Guest repliedNo more complicated than making an ordinary redneck spring compressor?Originally posted by almarconi View Post

Guest repliedNo more complicated than making an ordinary redneck spring compressor?Originally posted by almarconi View Post

-

Guest repliedThe compressed air will hold the valve in place but you still need something to compress the spring so you can get the keeper installed. This is not a job I would look forward to doing with the head on the bike.I've read that it can be done by pressuring up the cylinder with an airline.

Guest repliedThe compressed air will hold the valve in place but you still need something to compress the spring so you can get the keeper installed. This is not a job I would look forward to doing with the head on the bike.I've read that it can be done by pressuring up the cylinder with an airline.

Leave a comment:

-

Guest repliedI've read that it can be done by pressuring up the cylinder with an airline. Guess you'd need a fairly high pressure. Sounds feasible, I'll try it next time I need new seals.Originally posted by 1980GS1000E View PostAny ideas on how to do this with the head installed if you just wanted to change the seals? The valves can be kept in place by stuffing rope into the cylinder through the spark plug hole, but how to secure the valve spring compressor to the frame?Last edited by Guest; 03-01-2013, 04:47 PM.

Guest repliedI've read that it can be done by pressuring up the cylinder with an airline. Guess you'd need a fairly high pressure. Sounds feasible, I'll try it next time I need new seals.Originally posted by 1980GS1000E View PostAny ideas on how to do this with the head installed if you just wanted to change the seals? The valves can be kept in place by stuffing rope into the cylinder through the spark plug hole, but how to secure the valve spring compressor to the frame?Last edited by Guest; 03-01-2013, 04:47 PM.

Leave a comment:

-

There is an overhead spring compressor. I have one from ebay.Originally posted by 1980GS1000E View PostAny ideas on how to do this with the head installed if you just wanted to change the seals? The valves can be kept in place by stuffing rope into the cylinder through the spark plug hole, but how to secure the valve spring compressor to the frame?

Leave a comment:

-

something that would bolt on to the head maybe? using the valve cover bolt holes....Originally posted by 1980GS1000E View PostAny ideas on how to do this with the head installed if you just wanted to change the seals? The valves can be kept in place by stuffing rope into the cylinder through the spark plug hole, but how to secure the valve spring compressor to the frame?

a bit of rummaging through a scrap pile i bet you could find something.

Leave a comment:

-

They way we used to do on car heads was bring the piston to the top. that way if the valve dropped the piston would stop it and you can still grab it to pull it back. As for depressing the valve spring we had a special pry bar for that. The pry bar locked on using the rocker arm stud using just a washer and nut. It then had a large flat type of washer welded to the pry bar that went over the spring cover/bucket with a decent hole in the middle.Originally posted by 1980GS1000E View PostAny ideas on how to do this with the head installed if you just wanted to change the seals? The valves can be kept in place by stuffing rope into the cylinder through the spark plug hole, but how to secure the valve spring compressor to the frame?

Once you compressed the spring the valve retainer came up through the hole and you could remove it then. You might be able to come up with a version for the bike head. Just remember, the longer the handle on the pry bar, the better the leverage.

Leave a comment:

-

Any ideas on how to do this with the head installed if you just wanted to change the seals? The valves can be kept in place by stuffing rope into the cylinder through the spark plug hole, but how to secure the valve spring compressor to the frame?

Leave a comment:

-

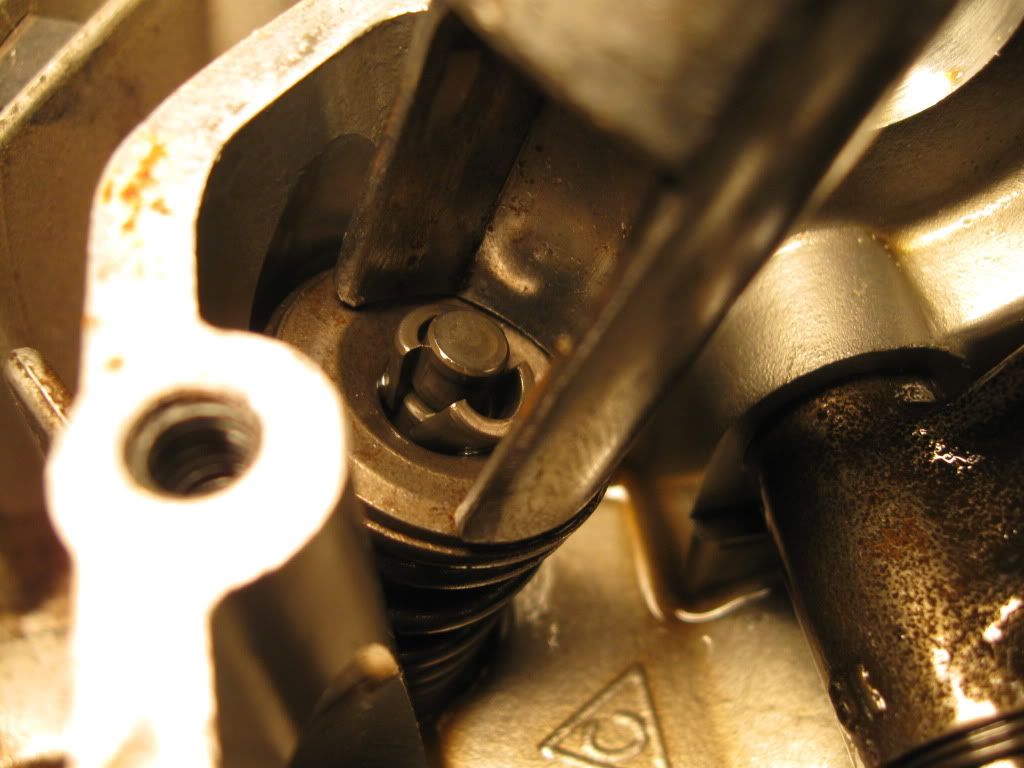

Wow, glad you got pics, Larry! I've been meaning to take a photo of that thing for a while.Originally posted by Larry D View Post

I forgot about one detail -- notice that I Dremeled a notch at the end of the C-clamp so I'd have a flat spot to drill the hole for the bolt. I made sure to use a higher-quality clamp, since the threads would be getting a lot of use -- cheap clamps tend to be sloppy.

I leave the bolt a little bit loose so the window in the socket can be turned whichever way it's needed. In that photo, the smaller 5/8" spark plug socket is mounted since we're working on a 16V engine.

Leave a comment:

-

Guest repliedI used a socket in a similar way for my valve compressor. I also painted the other side of the clamp with Plasti-Dip so that it wouldn't scratch the valves or chamber. Works great.

Guest repliedI used a socket in a similar way for my valve compressor. I also painted the other side of the clamp with Plasti-Dip so that it wouldn't scratch the valves or chamber. Works great.

Leave a comment:

-

Guest repliedI cut a window in both sides of a deep socket and use one of those cheap harbor freight quick release bar clamps. I've got different size sockets for the 8v and 16v heads.

Guest repliedI cut a window in both sides of a deep socket and use one of those cheap harbor freight quick release bar clamps. I've got different size sockets for the 8v and 16v heads.

Leave a comment:

-

Hey, this is a great thread. Cause it's only a matter of time before I do valves.

Leave a comment:

-

hmmm... i think i'll try to come up with a way to connect the gadget to the C clamp. to keep it straight and less wobbly.

and i gotta get me one of them dremels.

Leave a comment:

-

Yeah, I started with PVC, even made a video that is posted on BassCliff's site, but found that the PVC deforms too much.

It's also a bit "fiddly" trying to glue a washer to the end of the PVC to give the clamp something to push on.

After searching around for various bits of metal that would be stronger, I decided on a deep-well socket. Plenty strong sides, and the (mostly) closed end where the ratchet is attached just keeps the c-clamp from falling into the middle. That is the hole that Brian evidently uses to bolt it to the clamp.

.Last edited by Steve; 02-28-2013, 01:19 PM.

Leave a comment:

.png)

Leave a comment: