Announcement

Collapse

No announcement yet.

Need my head examined (beware monster pics)

Collapse

X

-

TheCafeKid

TheCafeKid

Ok, what I SHOULD have said is they are not what one would generally consider a "worn/replace" part, such as a piston ring wrist pin clip, etc. (of course if they get bad enough, you'll probably have to pitch em) however, polish beget polish, for piece of mind *I* would smooth the edges. Having seen what happens to upper fork tubes when the bushing gets a polish going, i can only assume the cylinder wall suffers for it. Again, im a shade tree mechanic, so I may be completely wrong. At any rate, you'll likely hone the bores so it probably doenst much matter, do what you think is best, and I will continue to do what I think is best

-

Everyone gets to be right here at the special school!Originally posted by TheCafeKid View Post...do what you think is best, and I will continue to do what I think is best Dogma

Dogma

--

O LORD, be gracious to me; heal me, for I have sinned against you! - David

Skeptical scrutiny is the means, in both science and religion, by which deep insights can be winnowed from deep nonsense. - Carl Sagan

--

'80 GS850 GLT

'80 GS1000 GT

'01 ZRX1200R

How to get a "What's New" feed without the Vortex, and without permanently quitting the Vortex

Comment

-

Arright. I had a couple little wire wheels so I did it Steve's way. I can see the T-shirt now: "GS riders do it Steve's way". Anyhow, the results are the same as his, so I didn't take a picture.

I also got some inspecting done. Piston diameter at the skirt, ring to groove gap, and free ring gap were all easily within normal limit, not even the service limits (according to Clymer). Consistent across all four, too. Basically, it's like new in there, except for the carbon. I didn't take the rings off and stuff them up the bore to check the gap there though. Not looking forward to that chore. How easy is it to accidentally break rings removing them? I'm thinking I should use snap ring pliers to expand them.

I also picked up ingredients for a valve spring compressor. I hope to get the valves out before I take the head to Pearson's on Saturday. I sure hope he can get it done on Saturday. I'll be in great shape if I can get the seals and valves back in this weekend.

Speaking of seals... the left fork seal decided to make a puddle sometime in the last 24 hours. Just wonderful. Well, Jim predicted those pitted tubes would cause an early failure. Time to swap on the new set, I suppose. That'll give me something to do if I don't get the head back this weekend. Let's hope those seals are still good.Dogma

--

O LORD, be gracious to me; heal me, for I have sinned against you! - David

Skeptical scrutiny is the means, in both science and religion, by which deep insights can be winnowed from deep nonsense. - Carl Sagan

--

'80 GS850 GLT

'80 GS1000 GT

'01 ZRX1200R

How to get a "What's New" feed without the Vortex, and without permanently quitting the Vortex

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35291

- Torrance, CA

You can remove the valve locks by placing a socket over the retainer and giving it a good wack with a rubber mallet. Stuffing a wadded up rag in the combustion chamber helps by keeping the valves seated. I've used this trick several times with success. Lynn mentioned this trick in a thread a few years ago so she gets credit. Ed

Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

p_s

p_s

+1 but also stuff some paper towel in the socket. I also used my hands to put them back on instead of a home-made compressor--but I'd guess that's much easier on a 16-valve 550.Originally posted by Nessism View PostYou can remove the valve locks by placing a socket over the retainer and giving it a good wack with a rubber mallet. Stuffing a wadded up rag in the combustion chamber helps by keeping the valves seated. I've used this trick several times with success. Lynn mentioned this trick in a thread a few years ago so she gets credit.

Comment

-

MY way??? What are you talking about???Originally posted by Dogma View PostArright. I had a couple little wire wheels so I did it Steve's way.

The posters, so far, in order of appearance:

Dogma - Dale

First timer - ??

Posplayr - Jim

Nessism - Ed

Steve - Steve

TheCafeKid - Josh

Chef1366 - Bill

Dreef1999 - ??

Tkent02 - Tom

Dave8338 - Dave

I seem to be the only "Steve" so far, and all I suggested was smaller pictures.

But, ... since you are under the impression that I suggested wire wheels, let me confirm that impression.

This is how we cleaned the pistons in #2 son's 850 last summer:

.sigpic

mine: 2000 Honda GoldWing GL1500SE and 1980 GS850G'K' "Junior"

hers: 1982 GS850GL - "Angel" and 1969 Suzuki T250 Scrambler

#1 son: 1986 Yamaha Venture Royale 1300 and 1982 GS650GL "Rat Bagger"

#2 son: 1980 GS1000G

Family Portrait

Siblings and Spouses

Mom's first ride

Want a copy of my valve adjust spreadsheet for your 2-valve per cylinder engine? Send me an e-mail request (not a PM)

(Click on my username in the upper-left corner for e-mail info.)

Comment

-

TheCafeKid

TheCafeKid

I have a spare set I am about to send back because they werent the right ones for the 550 i just did. They WILL work on your 850 tho. Changing the fork seals takes me about an hour, Ive got lots of practice in this week...lol Let me know if you need them, if you can by tomorrow, and I wont send them back. I take it you DID get ahold of Pearsons after all?Originally posted by Dogma View PostArright. I had a couple little wire wheels so I did it Steve's way. I can see the T-shirt now: "GS riders do it Steve's way". Anyhow, the results are the same as his, so I didn't take a picture.

I also got some inspecting done. Piston diameter at the skirt, ring to groove gap, and free ring gap were all easily within normal limit, not even the service limits (according to Clymer). Consistent across all four, too. Basically, it's like new in there, except for the carbon. I didn't take the rings off and stuff them up the bore to check the gap there though. Not looking forward to that chore. How easy is it to accidentally break rings removing them? I'm thinking I should use snap ring pliers to expand them.

I also picked up ingredients for a valve spring compressor. I hope to get the valves out before I take the head to Pearson's on Saturday. I sure hope he can get it done on Saturday. I'll be in great shape if I can get the seals and valves back in this weekend.

Speaking of seals... the left fork seal decided to make a puddle sometime in the last 24 hours. Just wonderful. Well, Jim predicted those pitted tubes would cause an early failure. Time to swap on the new set, I suppose. That'll give me something to do if I don't get the head back this weekend. Let's hope those seals are still good.

Comment

-

An hour for fork seals? That sounds about right, if you hustle. Yeah, hang on to those for me please. We can do the new forks, seals and progressives at the same time. But some time after it has a whole engine again.Originally posted by TheCafeKid View PostI have a spare set I am about to send back because they werent the right ones for the 550 i just did. They WILL work on your 850 tho. Changing the fork seals takes me about an hour, Ive got lots of practice in this week...lol Let me know if you need them, if you can by tomorrow, and I wont send them back. I take it you DID get ahold of Pearsons after all?

Yeah, I did get hold of Pearson's. I'll drop the parts off with the man himself Saturday morning.Dogma

--

O LORD, be gracious to me; heal me, for I have sinned against you! - David

Skeptical scrutiny is the means, in both science and religion, by which deep insights can be winnowed from deep nonsense. - Carl Sagan

--

'80 GS850 GLT

'80 GS1000 GT

'01 ZRX1200R

How to get a "What's New" feed without the Vortex, and without permanently quitting the Vortex

Comment

-

Them's the pics I saw somewhere. I thought it was here. Maybe they were posted in one of hte linked threads on wlanut shells? Thanks for clarifying for those who must have been wondering.Originally posted by Steve View PostMY way??? What are you talking about???

The posters, so far, in order of appearance:

Dogma - Dale

First timer - ??

Posplayr - Jim

Nessism - Ed

Steve - Steve

TheCafeKid - Josh

Chef1366 - Bill

Dreef1999 - ??

Tkent02 - Tom

Dave8338 - Dave

I seem to be the only "Steve" so far, and all I suggested was smaller pictures.

But, ... since you are under the impression that I suggested wire wheels, let me confirm that impression.

This is how we cleaned the pistons in #2 son's 850 last summer:

[pics deleted]

.Dogma

--

O LORD, be gracious to me; heal me, for I have sinned against you! - David

Skeptical scrutiny is the means, in both science and religion, by which deep insights can be winnowed from deep nonsense. - Carl Sagan

--

'80 GS850 GLT

'80 GS1000 GT

'01 ZRX1200R

How to get a "What's New" feed without the Vortex, and without permanently quitting the Vortex

Comment

-

It must be easier on the 16V. I just walked out to the garage to try it, and the valve didn't even budge with anything that felt like reasonable force. Or maybe I'm a wimp.Originally posted by p_s View Post+1 but also stuff some paper towel in the socket. I also used my hands to put them back on instead of a home-made compressor--but I'd guess that's much easier on a 16-valve 550.Dogma

--

O LORD, be gracious to me; heal me, for I have sinned against you! - David

Skeptical scrutiny is the means, in both science and religion, by which deep insights can be winnowed from deep nonsense. - Carl Sagan

--

'80 GS850 GLT

'80 GS1000 GT

'01 ZRX1200R

How to get a "What's New" feed without the Vortex, and without permanently quitting the Vortex

Comment

-

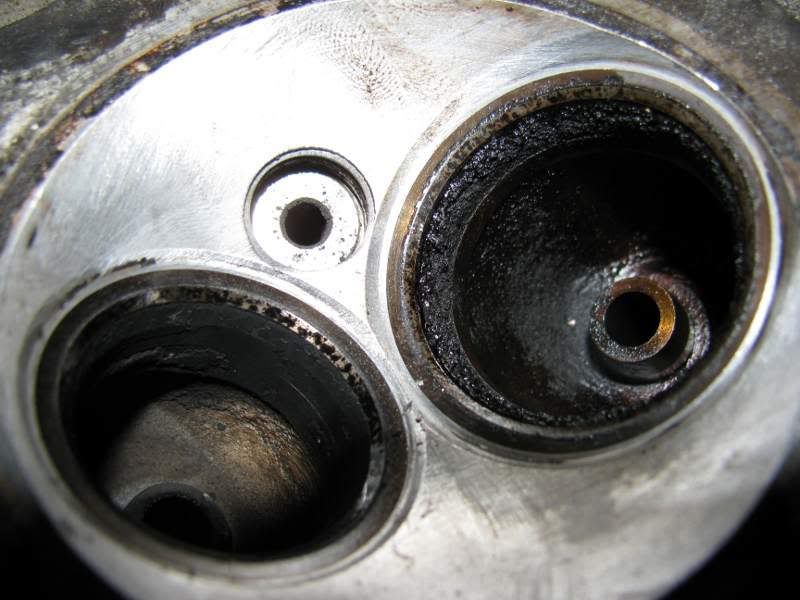

The results of tonight's efforts... Cleaned the chambers and valve faces, made the spring compression tool, got the valves out and inspected everything I could. Not a bad evening's work.

Not sure what the camera was focusing on here, but that's a 1" galvanized pipe nipple all carved up with a washer taped on top. A half inch shorter would have been perfect for my 6" C-clamp. It took almost as long to make this thing as it took to use it. The bottom end looks burnt because I ground almost a mm off the diameter to make sure it was smooth and would fit easily into the head. The fit was too close for comfort.

Here's the #1 chamber with the fitting stuck in it. Much cleaner! More wire wheel work. I cleaned the valves at the same time, but didn't get a pic.

I took 9MP macro shots of all 4 chambers to look for pits. Basically using the camera as a magnifying glass.

Well, all the valve stem diameters are within standard limits, maybe just outside. I'm not going to argue tenths or microns with a Harbor Freight micrometer. Anyhow, easily within service limits.

The inner springs are smack in the middle of the standard tolerances. The outer springs are a little tired, but easily within service limits.

Everything was very consistent across all cylinders except valve shake. The valves in #1 had almost no shake. I may have imagined that I felt it. The valves in 2, 3, and 4 had visible shake. I guestimated it at about .13[.005]. Really. Service limit is .35.

So, everything is like new or within service limits. The only thing I haven't measured is the ring gap in the cylinder. Go ahead and ask me if I still think this thing was blowing oil out the crankcase breather.

Josh, that gasket kit turned out to be a Vesrah. Looking at the head gasket as closely as I can without unpacking it, and comparing it to what's left of the original, construction seems to be of the same type. Not different like some reports I've read here (Or was that Cometic?). If someone else was asking me though, I know I'd tell them to spend the money and not worry about it while in WV. Any tips on where to find an OEM kit, or at least the head gasket? I'm not having much luck. Anyone have recent success stories with the Vesrah?

Oh, and what's the best way to get the valve seals off? Tenacious little devils. Go after 'em with side cutters first?Dogma

--

O LORD, be gracious to me; heal me, for I have sinned against you! - David

Skeptical scrutiny is the means, in both science and religion, by which deep insights can be winnowed from deep nonsense. - Carl Sagan

--

'80 GS850 GLT

'80 GS1000 GT

'01 ZRX1200R

How to get a "What's New" feed without the Vortex, and without permanently quitting the Vortex

Comment

-

TheCafeKid

TheCafeKid

Carefully on the valve seals, but dont be dainty. They're tenacious, yes, but the stems are pretty tough. Just try not to go ape sh1t on em...

The bad thing is, getting an OEM Suzuki headgasket from BB or where ever is likely going to cost you more than that WHOLE Vesrah kit. I think the last time i priced one it was 95 bucks just for the head gasket. However, I bit the bullet and bought one and the base gasket because i wasnt chancing it to another Vesrah kit. Worst case scenario, the Vesrah kit leaks, you have to replace it. Couple hours, you'll have lots of practice at least

That's pretty sweet you got ahold of Pearson. Like I said, Ive not taken anything yet, simply because i havent had to, but come this winter when i get into the guts of my ES, EVERYTHING will be going there....he comes HIGHLY recommended...

Comment

-

Forum LongTimerGSResource Superstar

Past Site Supporter

Super Site Supporter- Mar 2006

- 35291

- Torrance, CA

The service limit for valve to stem clearance is .090 mm (.0035") for intake and .100 mm (.0039") for exhaust. It doesn't take much valve and guide wear to throw this measurement out of spec. If you are estimating .13mm [.005"] (which is out of spec), I recommend you get the proper equipment and measure it. I did this on three different GS1000 heads before finding one that was still within the service limit. Unfortunately, servicing the head with new guides and a valve job costs several hundred dollars; finding a clean used head off ebay is far cheaper, even if you have to buy more than one before you get a good one.Originally posted by Dogma View PostEverything was very consistent across all cylinders except valve shake. The valves in #1 had almost no shake. I may have imagined that I felt it. The valves in 2, 3, and 4 had visible shake. I guestimated it at about .13[.005]. Really. Service limit is .35.

Photo below shows how to check with a dial indicator. To get a proper measurement you need to lift the valve off the seat to a point near the full open point for the valve, about .400" in the case of our GS engines.

Last edited by Nessism; 06-26-2009, 11:46 AM.Ed

Last edited by Nessism; 06-26-2009, 11:46 AM.Ed

To measure is to know.

Mikuni O-ring Kits For Sale...https://www.thegsresources.com/_foru...ts#post1703182

Top Newbie Mistakes thread...http://www.thegsresources.com/_forum...d.php?t=171846

Carb rebuild tutorial...https://gsarchive.bwringer.com/mtsac...d_Tutorial.pdf

KZ750E Rebuild Thread...http://www.thegsresources.com/_forum...0-Resurrection

Comment

-

Ed, thanks for auditing my results. Apparently, things are different for the 850. According to my copy of the factory service manual, standard specs for "valve guide - valve stem clearance" is 0.025-0.055 with a service limit of 0.35 for intake and 0.040-0.070 / 0.35 for exhaust.

Am I misinterpreting the whole standard / limit thing? If so, I'll bust out my indicator and take a more accurate reading for sure.Dogma

--

O LORD, be gracious to me; heal me, for I have sinned against you! - David

Skeptical scrutiny is the means, in both science and religion, by which deep insights can be winnowed from deep nonsense. - Carl Sagan

--

'80 GS850 GLT

'80 GS1000 GT

'01 ZRX1200R

How to get a "What's New" feed without the Vortex, and without permanently quitting the Vortex

Comment

.png)

Comment