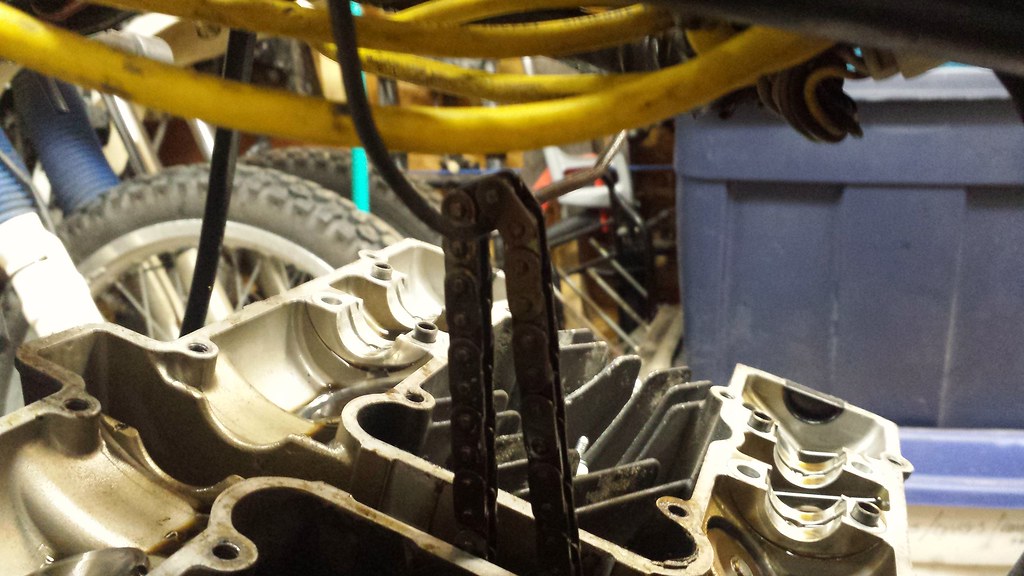

I didn't take too many pictures of the first step of removing all the bits and pieces, the manual describes that well enough. About the only piece of info it doesn't mention is that when you are taking off the cam holders it's best to loosen each of the 4 bolts a bit at a time, criss cross from eachother, rather than one at a time. That way you avoid stripping any of the threads. Make sure you hang up the cam chain as well

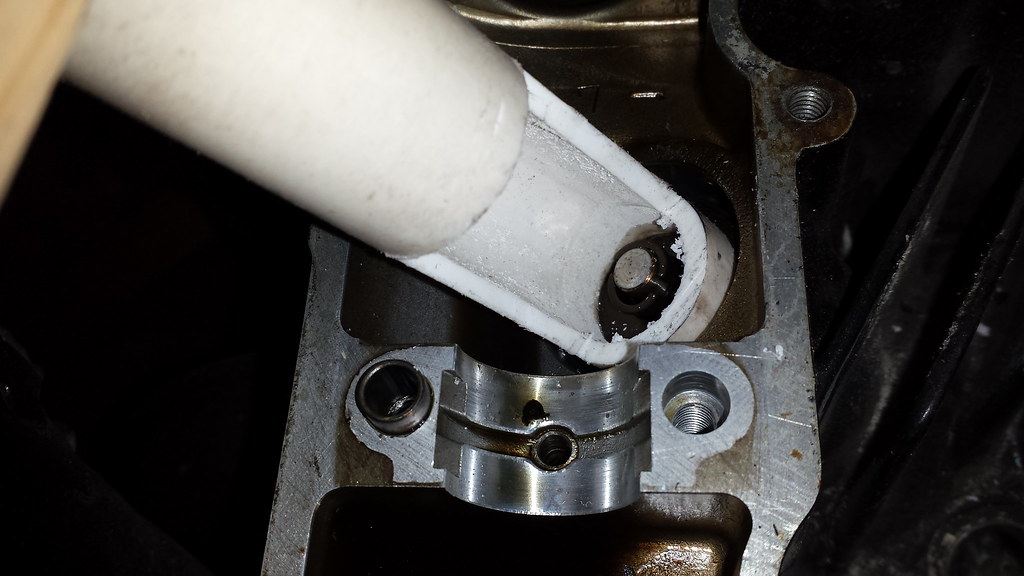

Hang cam chain by Rob Ert, on Flickr

Hang cam chain by Rob Ert, on FlickrI actually changed it from a single wire to a couple of PVC pipes later so that when I was rotating the crank the chain would easily turn as well. You can probably see it in one of the other pictures.

I tell you, getting the shims out once the cams are off is a lot easier

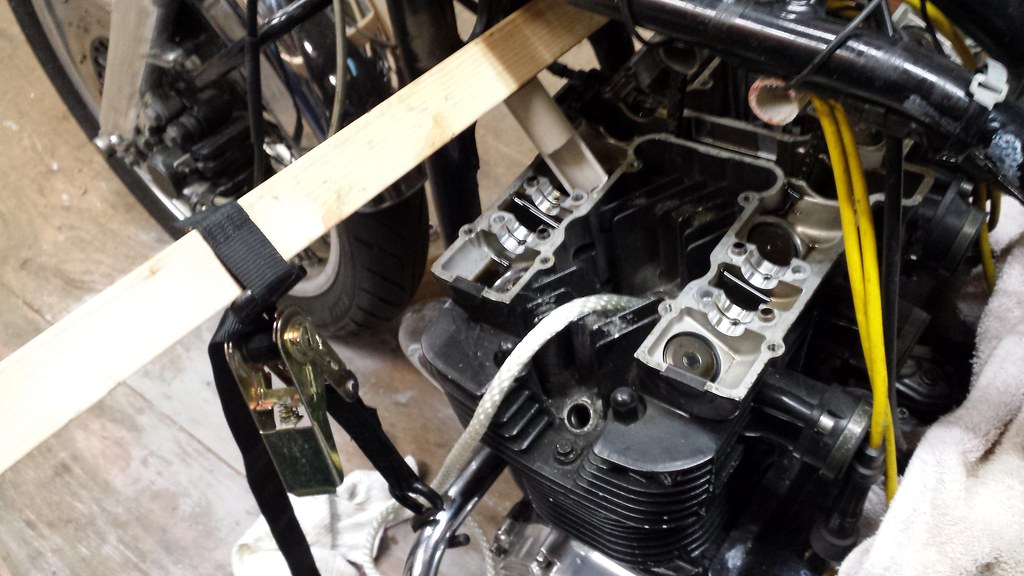

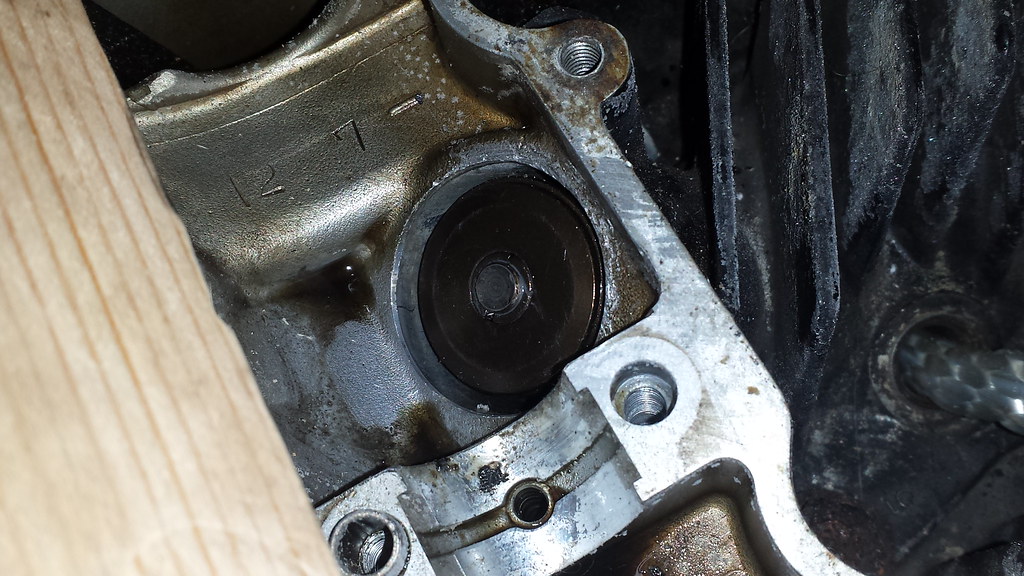

2016-11-14_09-35-33 by Rob Ert, on Flickr

2016-11-14_09-35-33 by Rob Ert, on FlickrAn essential tool to this process is a retractable magnet as seen in that photo. Once all the shims and buckets are out I started trying to figure out how I was going to use a piece of wood as leverage to compress the valve springs.

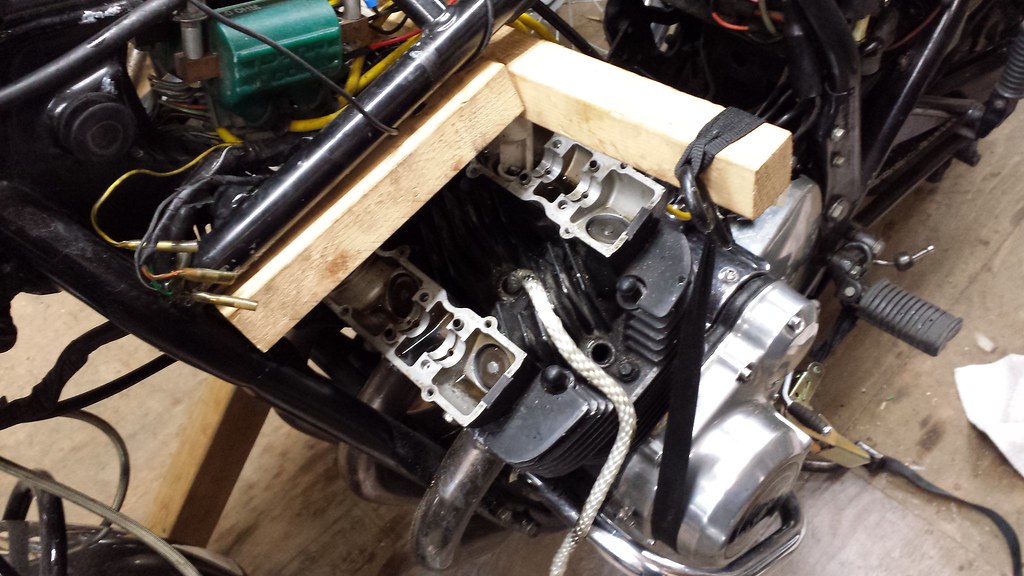

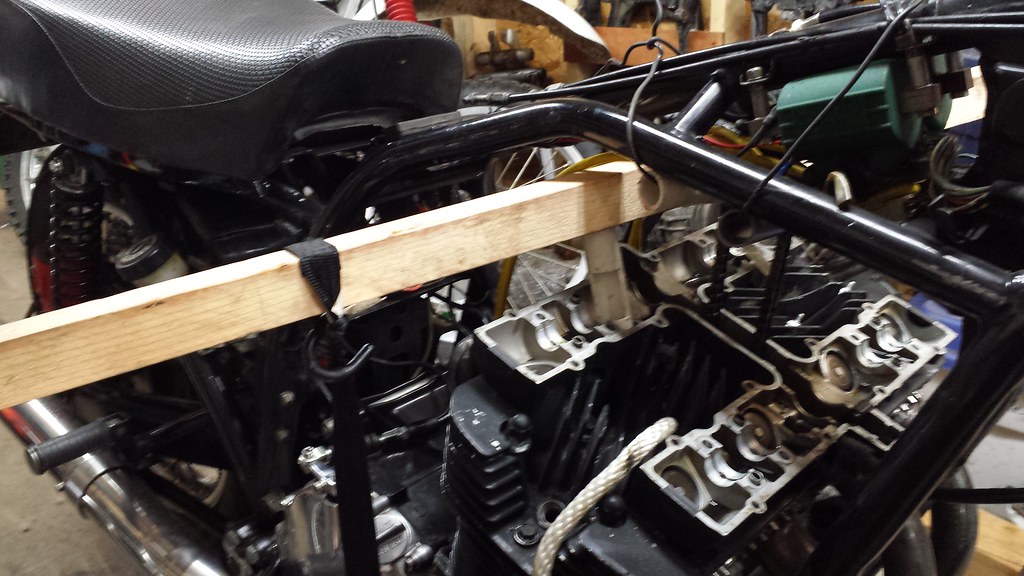

20170105_104323(0) by Rob Ert, on Flickr

20170105_104323(0) by Rob Ert, on FlickrI used the shelving to brace the 2x2 and a 4x4 to support it. I used some nylon rope down the spark plug hole, then turned the crankshaft until it would turn no further and put a 2x6 between the wrench and the case saver to stop it from turning backwards when I compressed the valve springs. I made sure the 2x2 extended well beyond the side of the engine so my ratchet strap would easily grab it. Had to make a couple of different length 'PVC valve clip removal specialty tools' (or what ever the heck it's called) for getting at the clips.

20170105_104323(0) by Rob Ert, on Flickr

20170105_104323(0) by Rob Ert, on Flickr 20170105_104307 by Rob Ert, on Flickr

20170105_104307 by Rob Ert, on Flickr#2 exhaust by far was the worst one to get at but as I went along I figured out which was the best tool to use to get the old valve seal out.

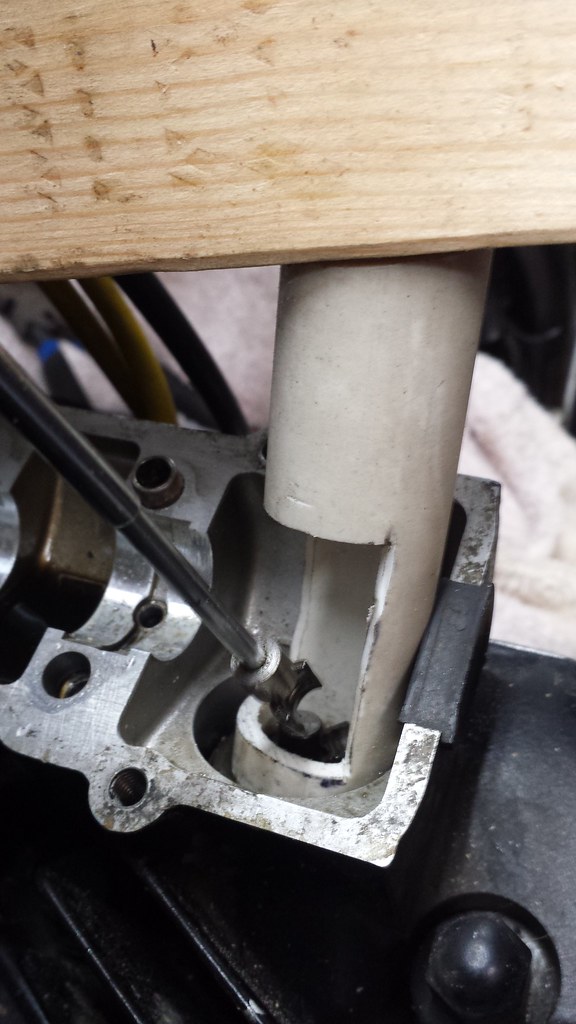

This tool turned out to be great for getting the old valve seals out, and for putting the clips back in

20170105_151734 by Rob Ert, on Flickr

20170105_151734 by Rob Ert, on FlickrA 1/4 inch 10mm deep socket was perfect for lightly seating the new valve seals

20170105_112611 by Rob Ert, on Flickr

20170105_112611 by Rob Ert, on FlickrOnce you have the rope in and the valve remains up while compressing the springs do both the intake and exhaust for the cylinder, better to do both than have to put the rope in twice. I came up with many different scenarios with the ratchet strap to make this all work.

20170105_154607 by Rob Ert, on Flickr

20170105_154607 by Rob Ert, on FlickrI had to use some wedges as well to stop the 2x2 from moving too much while pulling it down so the PVC would stay in place.

20170105_121355 by Rob Ert, on Flickr

20170105_121355 by Rob Ert, on Flickr

.png)

, so in the end I'm one happy camper.

, so in the end I'm one happy camper.

Comment