They either have no oil hole where they should, have an extra oil hole, or have an oil groove where there shouldn't be one.

What I'm most concerned with are the new rod bearings which no longer have oil holes in them. All the rod bearings from my original crankshaft have oil holes in them, and the diagram on the ordering form show them with oil holes, and the crankshaft itself has oil passages in it to feed the rods. I spoke with Corey from PartsOutlaw.com and he called Suzuki for me but couldn't get confirmation as to why the parts were changed. Apparently some parts are modified over the years. Suzuki insists these are all the correct parts for my bike and should work in the bike just fine. I'm a little nervous about putting the rod bearings in without an oil hole. Corey said I could return them for no restocking fee if I want. That's pretty cool.

I've noticed a few other threads on this issue on the forum but none had a resolution. Anybody have a clue what I should do?

I'm thinking of returning them and checking on ebay for replacement parts with the original part number and if all else fails, I'll machine my own holes where necessary.

The new bearing is on the right, and the old one with the oil hole is on the left in the photo.

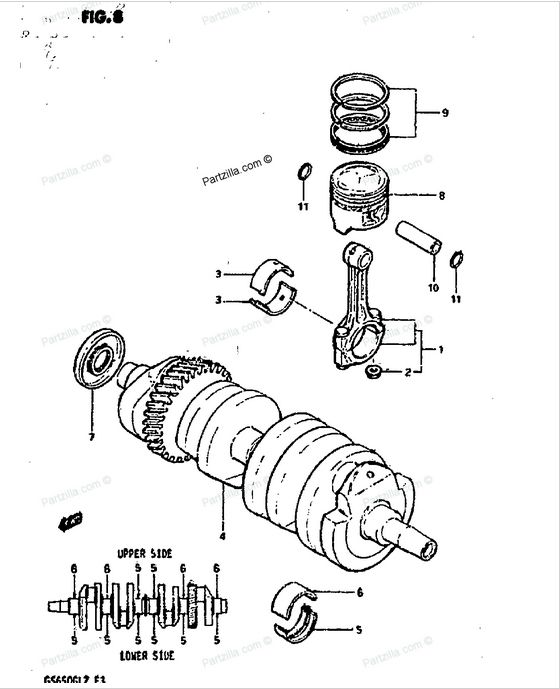

As far as my understanding six of the eight upper crankshaft bearings should have no oil grooves or holes. Whereas the the inner two upper bearings are the same as the lower bearings with both a groove and two holes. Again, just like in the diagram below.

But the upper crankshaft bearings I received have oil grooves. The original bearing is to the left while the two in plastic are new. I'm not as worried about these. So there's a little more oil distribution along the crank. Seems fine, but I'm no mechanic. Should I be worried?

And the one lower bearing I received so far has three holes, but the original bearing below it only has two. The new one is in plastic. Also seems like not a big deal, but I'm new at this and don't want to ruin my engine.

Any help is appreciated.

Comment