I wasn't able to knock the studs out, I cut the end flush and drilled a 10mm hole right through the middle of the stud to allow bolts to pass through. I used two zinc plated round head bolts that are used on timber (you know the ones with the domed head and square shank that bites into the wood?), dunno what theyre called. They fit perfect into the rubber mount and top yoke, allowing me to keep the rubber mounts.

I flipped the headlight brackets over and dropped the gauges to 15mm above the headlight to allow for any movement in the rubbers. Had to drop the ignition to suit as well.

This is a subtle change to the appearance of the bike but in my opinion, it was well worth it. Cheers for the hints n tips, much appreciated.

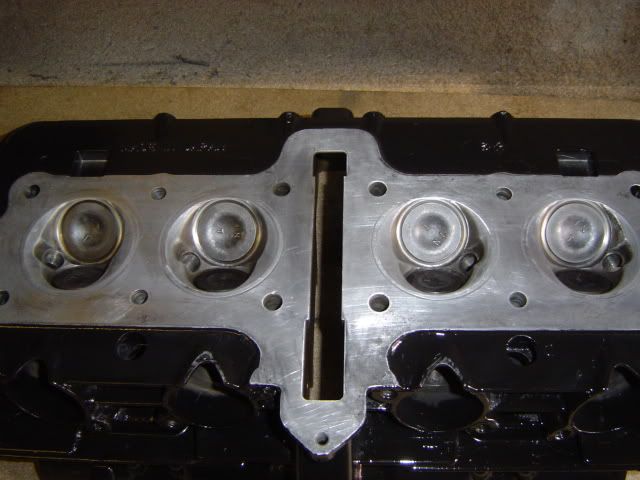

. Custom wiring loom can now progress too. The rebuilt head was at a standstill until my good friend Bribird came to the rescue with the two inner exhaust valves and a full set of springs, he's supplying some bits for the carbs too, ohhh, and a master cylinder (again, hopefully). He's got nearly as much in this project as me now, cheers Bribird, you are a star!

. Custom wiring loom can now progress too. The rebuilt head was at a standstill until my good friend Bribird came to the rescue with the two inner exhaust valves and a full set of springs, he's supplying some bits for the carbs too, ohhh, and a master cylinder (again, hopefully). He's got nearly as much in this project as me now, cheers Bribird, you are a star!

i love how you hid the batt/electrics in the seat

i love how you hid the batt/electrics in the seat

Comment