Is there a trick to it?

I'm really hoping this doens't mean my CV Boot is warn out.

thanks,

Required reading for all forum users!!!

Welcome!

Register to access the full functionality of the GSResources forum. Until you register and activate your account you will not have full forum access, nor will you be able to post or reply to messages.

A note to new registrants...

All new forum registrations must be activated via email before you have full access to the forum.

A Special Note about Email accounts!

DO NOT SIGN UP USING hotmail, outlook, gmx, sbcglobal, att, bellsouth or email.com. They delete our forum signup emails.

A note to old forum members...

I receive numerous requests from people who can no longer log in because their accounts were deleted. As mentioned in the forum FAQ, user accounts are deleted if you haven't logged in for the past 6 months. If you can't log in, then create a new forum account. If you don't get an error message, then check your email account for an activation message. If you get a message stating that the email address is already in use, then your account still exists so follow the instructions in the forum FAQ for resetting your password.

Have you forgotten your password or have a new email address? Then read the forum FAQ for details on how to reset it.

Any email requests for "can't log in anymore" problems or "lost my password" problems will be deleted. Read the forum FAQ and follow the instructions there - that's what we have one for...

New users should be sure to read the FAQ as well as the posts in the Announcements forum. This will answer many of the questions you may have about how this forum works.

Before posting questions in the forums be sure to use the forum search function!!! Odds are your question has already been asked and answered before. And when posting, please make sure that you post to the correct forum.

Finally, be sure to check out BassCliff's website here. He has useful information that can't be found on this site. His welcome page containing useful GS information can be found here. Be sure to check it out!

If you are a returning visitor to the forum and can't log in using your old forum name and password, chances are your account is deleted. Just create a new forum account and you should be all set.

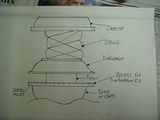

Hi ACR, this diagram shows the best way to put diaphragms back into your carbs,push the rubber down until it looks like an umbrella then put a little grease into the groove in the main carb body that the rubber sits in and grab the stem that holds the needle in place with a pair of pliers, and gently lower the diaphragm into place noting the locating lug moulded into the rubber of the diaphragm is seated correctly in the cut out in the casting-the grease will stop the diaphragm lifting again when you put the spring and cap on.I have used this methop many times and have yet to have a diaphragm lift on me, just be careful that the locating lug is in the correct place as if you nip it off the diaphragm is scrap!. hope this helps. Johnny

Hi ACR, this diagram shows the best way to put diaphragms back into your carbs,push the rubber down until it looks like an umbrella then put a little grease into the groove in the main carb body that the rubber sits in and grab the stem that holds the needle in place with a pair of pliers, and gently lower the diaphragm into place noting the locating lug moulded into the rubber of the diaphragm is seated correctly in the cut out in the casting-the grease will stop the diaphragm lifting again when you put the spring and cap on.I have used this methop many times and have yet to have a diaphragm lift on me, just be careful that the locating lug is in the correct place as if you nip it off the diaphragm is scrap!. hope this helps. Johnny

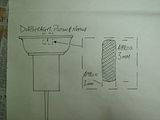

here are the other 2, Redman wanted to know if his diaphragms were holed and I have a set of scrap ones so I did these to show him what the damage looks like.Mabye someone else can find them useful, but they are really rough!!.Johnny

here are the other 2, Redman wanted to know if his diaphragms were holed and I have a set of scrap ones so I did these to show him what the damage looks like.Mabye someone else can find them useful, but they are really rough!!.Johnny

Comment