pic to show the bit of rust on the battery box,.....but the camera was in use outside of my reach

and away from home when i was doing the work.

.......but then,.....i guess we ALL know what a little rust looks like on these old girls!

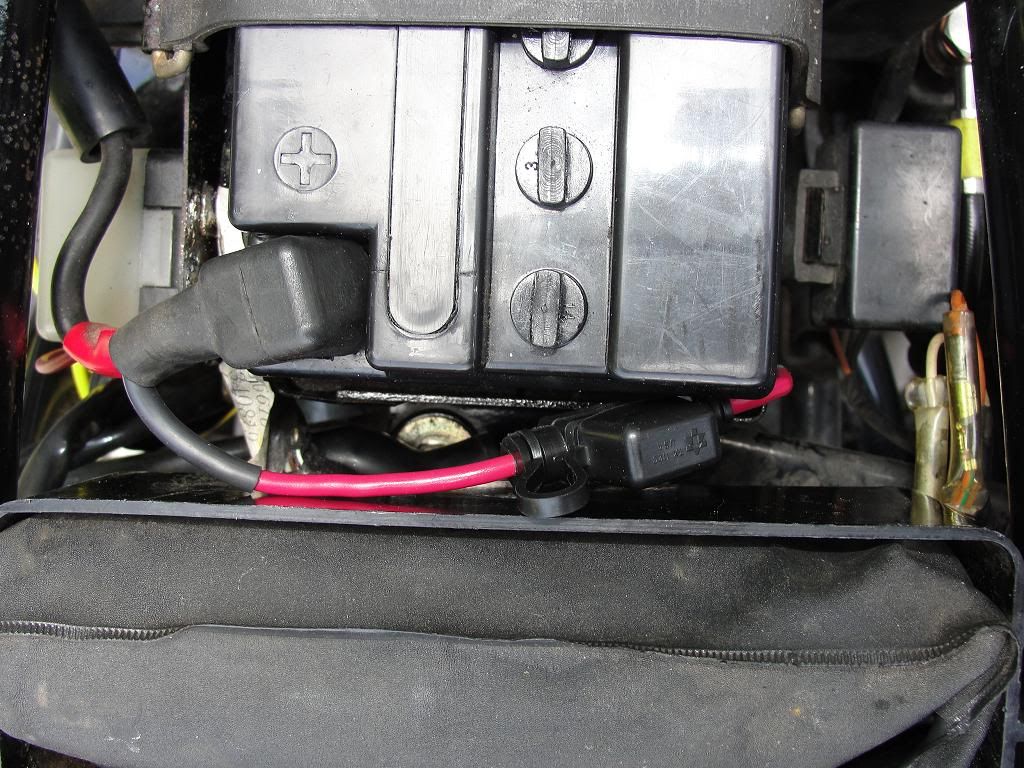

Here is the cleaned up battery compartment, with the "Mini-Fuse" in line on the pos+ lead. I used

a 30A fuse originally, but just changed it to a 15A as i'm thinking it's a bit safer that way. Not sure

why roadstercycle.com uses a 30A auto reset breaker on the pos+ wire in their videos?

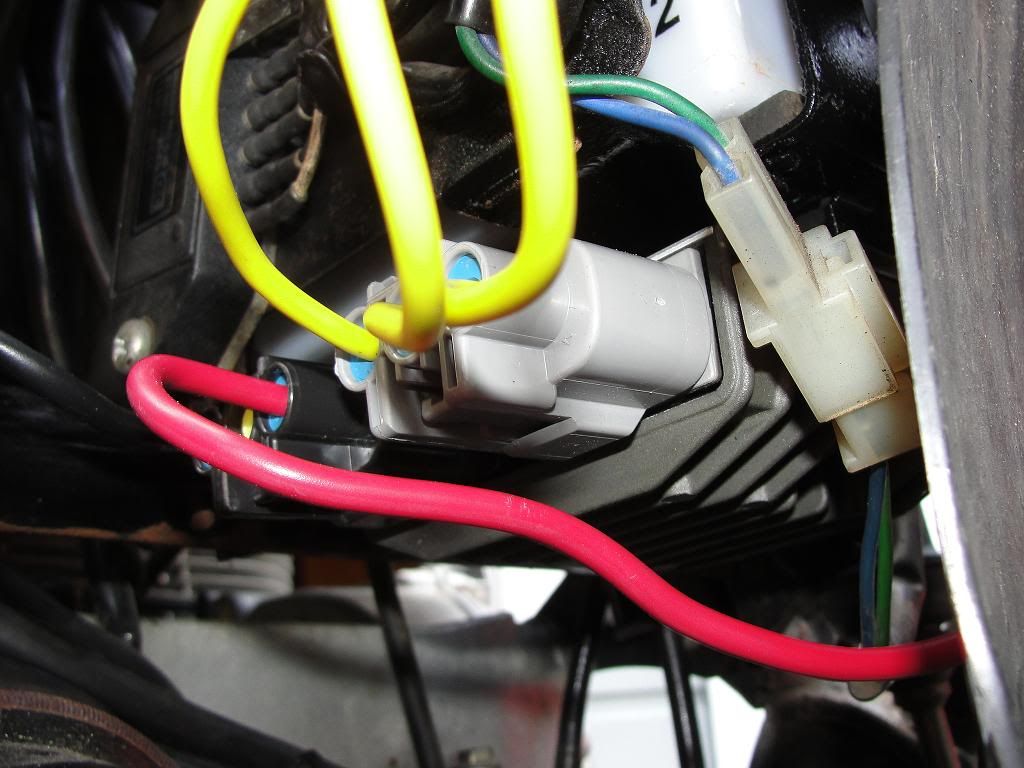

On the 3 stator wire hookups, i used gold plated spade connectors that i soldered BOTH sides on,

....even the stator wire side. In this case they only had the female side connectors with gold plating.

but i'm sure gold plated male connectors are available.

Because the OEM stator wires were much thinner than the 12G i used

on the R/R side, i folded the wires once to get a good crimp on them, and then soldered.

Before folding the wire ends over on themselves, i lightly sanded the old wires with 220 grit

sandpaper between my fingers. Got some copper showing

for a good solder joint. The un-heated shrink tubing (about 5-6" on each stator wire connection),

serves as a rain guard and is a decent friction fit over the connections. (the store didn't have the

weatherproof type) After the pics the cover was slid back over the connection.

....an overall view of the install. (sheath to cover spade connection still not slid back)

Here the protective slide cover back over the connection. I used dielectric grease to protect the connections from oxidation under the pulled over shring wrap, since the ends aren't sealed. Easy to get at the connections should the need arise.

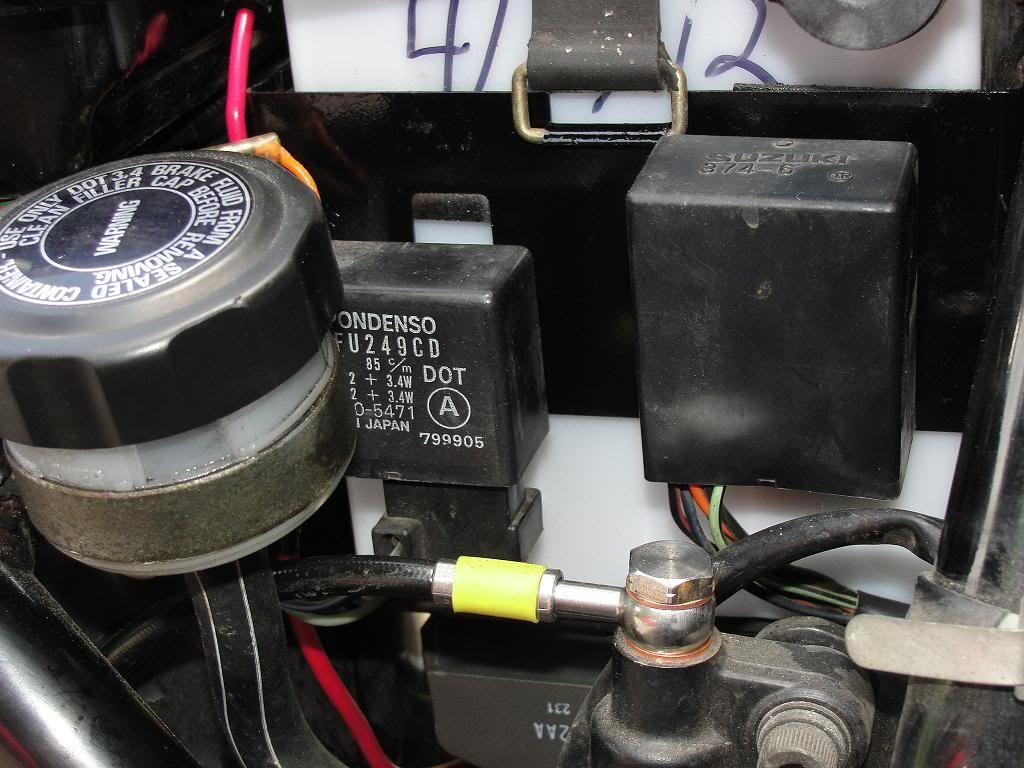

If you have phillips screws holding your OEM R/R onto the bottom of your battery box, i guarantee

you'll have to remove your battery box like i did to get the old R/R off!

This screw on the right side i had to hand saw a slot into, in order to get this entire side plate off.

(so you don't have to remove the electrical parts individually)

It is the screw i'm pointing at with a large flat screwdriver blade. The new screw/bolt combination is

one i had from an old battery connection,.....but any 6 sided bold will work fine.

Avoid the phillips screws,....a real PITA to get off usually!

You can see the other original phillips head on the left side of the starting solinoid,...still frozen but if

the solinoid needs replacing i'll deal with it then.

The 2 rectangular shaped componants under the right side cover just lift off that side of the battery box:

An overall view of the unit installed:

I pulled the red wire down a bit to better show the nice plugs on this unit.....well sealed with the rubber

plugs the wires go through.

......closer view,....really like the removable connections on this FH012AA R/R, and it's NOW mounted

with 6 sided bolts to allow easy removal without having to tear out the battery box next time.

This is where some of the original stator wires connected under the left side cover.....i used heat shrink

tubing on the 2 male bullet connectors, .....the female connector was already protected with it's vinyl

cover. Then used electrical tape to keep them separate. Others will know these are no longer being used.

(especially the crap routing to the headlight area!)

.....and here neatly covered back up with the OEM rubber wire bundle sheath:

.png)

Comment