The first 10 units of the Solid State Power Box with the Rev C PCB's (no red wires) have been completed and delivered. See this video and an overview of the capability and installation.

Solid State Power Box STANDARD INSTALLATION

Collapse

X

-

Status Update 1/17/2014

The first 10 units of the Solid State Power Box with the Rev C PCB's (no red wires) have been completed and delivered. See this video and an overview of the capability and installation.

-

Link says "This video is private". Is it only for people who have purchased the SSPB?

My appreciation of technical innovation and natural curiosity makes me want to view all your videos, even though I have not (yet) purchased a SSPB.1981 GS850G "Blue Magic" (Bike Of The Month April 2009)

1981 GS1000G "Leo" (Bike Of The Month August 2023)Comment

-

Should be fixed now. I intended to make all the videos public.Comment

-

I have a preliminary Install manual completed tonight to complement the YouTube (and hopefully reduce) the number of videos.

Contact me at Solidstatepowerbox@gmail.com if you would like a copy of the install guide. It is a 13 page pdf file.Comment

-

1981 GS850G "Blue Magic" (Bike Of The Month April 2009)

1981 GS1000G "Leo" (Bike Of The Month August 2023)Comment

-

....you forgot website i guess it is not really done yet

i guess it is not really done yet

Sorry this was much more that I originally thought.

Thanks for the mention.Comment

-

I finished assembly on 3 more units tonight and bonded the pcb to the base. Needs a couple of days to harden.

A new development on crimping pins for the 10 pin Molex. You can do an excellent job using a $27 crimper.Comment

-

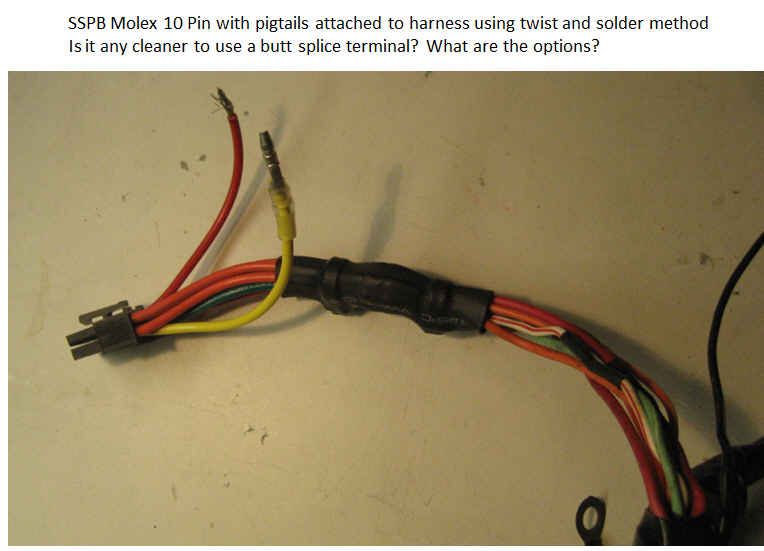

I have never used a butt splice connector; I usually strip back the insulation and intertwine the strands. I'm wondering if a splice terminal would be cleaner than the twist and solder method?

I need to place another Digikey order so if any body has any opinions chime in. The others from ebay are cheap enough and I will probably get some of those as well.

This is a picture of the spare harness with twist and solder heat shrink install.

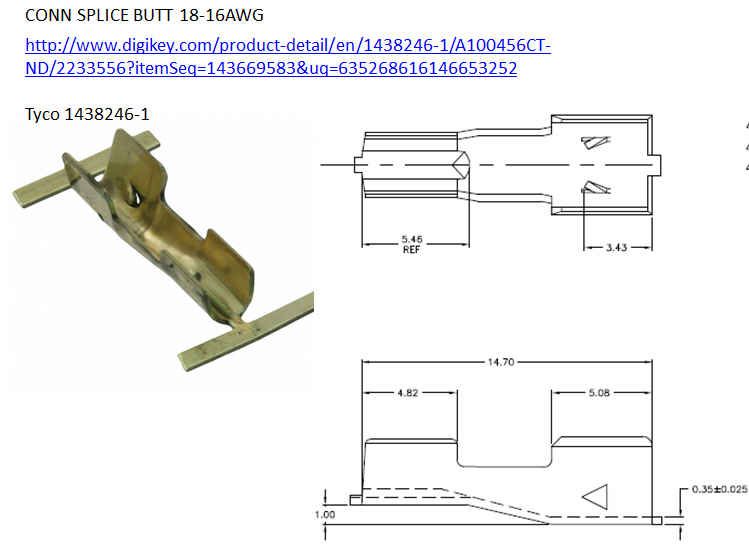

Option #1

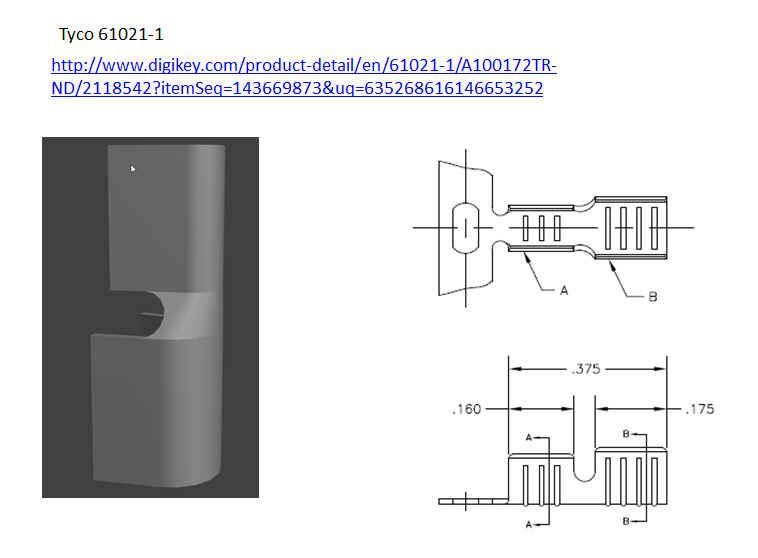

Option #2

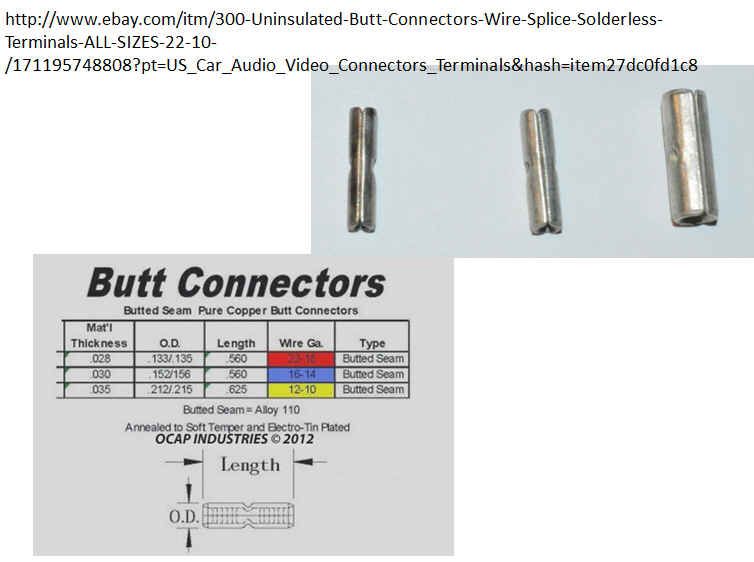

Option #3

Comment

-

The option 3 type are great if you use the correct size for your wire and if you have a real crimper. The one designed for that specific connector. The Walmart crimper or smashing it with pliers not so much.Comment

-

Looking to use one or the other of these.

Both available slightly cheaper on ebay or amazon.

The RTL gives the most leverage for open barrel crimps but the ETC-39 is most flexible,Last edited by posplayr; 02-01-2014, 06:53 PM.Comment

-

Last edited by posplayr; 02-02-2014, 01:20 PM.Comment

-

TooManyToys

TooManyToys

First, Jim I haven't even taken my unit out of the shipping box yet. But I told you I would not install it until the spring.

We used to do a lot of work on vehicle harness systems. The Posi-locks were a great, reliable tool when we need to tap into or extend wires on a temporary basis. Much better then the 3M clamp into splices.

For permanent work we would do either the slice and solder with heat shrink tubing, or go with option 3 butt connectors (sometimes soldered as well) with shrink tube. The soldering decision often came depending if how large an area we could leave stiff as solder spread deep in the wire often was determined by the skill of the person working on the job. I have read that a good pro crimp was a better connection then the twist and solder and most of the newer aircraft wiring connections are now just crimped, no solder.

The decision also was based on if we wanted to reduce the bulge in the harness. I always staggered the connections to minimize the bulge, but when restoring a Mustang or Shelby I would reduce the copper wire stranding on each end by 1/3'd of the strand count, do a light twist then solder. This kept the copper width just a little over the parent wire and with good shrink wrap kept the slice hidden in a wrapped bundle. Never had an issue doing that and I've had the two Shelbys over 35 years and no issues, but the lapping was precise and when soldered did not leave an area thinner then the parent wire.

For solder I've always used Tri or Quad Eutectic solder as from my reading and experience it is the best, originally developed by Bell Labs as I understand it.Comment

-

Thanks Jack,First, Jim I haven't even taken my unit out of the shipping box yet. But I told you I would not install it until the spring.

We used to do a lot of work on vehicle harness systems. The Posi-locks were a great, reliable tool when we need to tap into or extend wires on a temporary basis. Much better then the 3M clamp into splices.

For permanent work we would do either the slice and solder with heat shrink tubing, or go with option 3 butt connectors (sometimes soldered as well) with shrink tube. The soldering decision often came depending if how large an area we could leave stiff as solder spread deep in the wire often was determined by the skill of the person working on the job. I have read that a good pro crimp was a better connection then the twist and solder and most of the newer aircraft wiring connections are now just crimped, no solder.

The decision also was based on if we wanted to reduce the bulge in the harness. I always staggered the connections to minimize the bulge, but when restoring a Mustang or Shelby I would reduce the copper wire stranding on each end by 1/3'd of the strand count, do a light twist then solder. This kept the copper width just a little over the parent wire and with good shrink wrap kept the slice hidden in a wrapped bundle. Never had an issue doing that and I've had the two Shelbys over 35 years and no issues, but the lapping was precise and when soldered did not leave an area thinner then the parent wire.

For solder I've always used Tri or Quad Eutectic solder as from my reading and experience it is the best, originally developed by Bell Labs as I understand it.

I guess there are a smorgasbord of options here. I'm mainly interested in options for people to install the SSPB Molex connector with pigtails to the end of the harness. As you know I did a video showing how to twist and solder with heat shrink. The bundle was pretty clean and not much larger than the original wire harness despite the overlapping splices. Given it is in the end of a service loop connecting to the fusebox the added bulk is really a minor consideration. I was more interested in immobilizing the soldered joints using shrink tubing. I also zip tied them which adds more bulk and is probably overkill. The 16 ga marine wire is relatively stiff especially in a 10 wire bundle with heat shrink.

So I'm guessing the butt connectors brass type butt connector #1,#2 are pretty small and end up being smaller than a twist and solder joint. The #3 option is stronger but probably a little bulkier but it also sounds like your preferred but splice solution.

Yes I'm aware of the great solder debate and yes was recently brought home when I found a soldered crimp nearly broken off of my R/R ground. It really stresses the point to not solder so much that you wick solder way into the wire strands. best to use a hot iron and only wet the ends of the strands at the open part of the crimp away from the insulation.

And if you are wondering what the point of heat shrink is on a ground lug, it is to support the insulation further to avoid unnecessary movement of wire strands. Understanding all of the pitfalls of soldering, I still like the notion that I'm permanently sealing the contact between strands and terminal end even if it is a crimped joint.

For the DIY crowd, with all the various crimpers and wire sizes and terminal ends that exists it is unlikely that a good and proper crimp will result for any combination. In this case a little solder will help as long as not overdone.

The posi-locks are being touted as a kind of semi permanent reusable connection.With some type of anti-corrosion treatment I can certainly see how it might be attractive to someone; but not nessesarily to a pureist

Comment

-

Jim,

Did you ever figure out something on charging back through the accessory port or is this still a No No?

Just so I know, not bothered either way as I will just leave my SAE pigtail connected to the battery if so.

By the way - I've done many thousands of miles on bikes with posi-tite & posi-tap connectors for non essentials (heated grips, relay trigger switches etc) & at this stage I think I'd trust one as a permanent connection for anything... They do waterproof ones now too which should be as good as anything out there....

Last edited by salty_monk; 02-03-2014, 07:35 PM.1980 GS1000G - Sold

Last edited by salty_monk; 02-03-2014, 07:35 PM.1980 GS1000G - Sold

1978 GS1000E - Finished!

1980 GS550E - Fixed & given to a friend

1983 GS750ES Special - Sold

2009 KLR 650 - Sold - gone to TX!

1982 GS1100G - Rebuilt and finished. - Sold

2009 TE610 - Dual Sporting around dreaming of Dakar..... - FOR SALE!

www.parasiticsanalytics.com

TWINPOT BRAKE UPGRADE LINKY: http://www.thegsresources.com/_forum...e-on-78-Skunk/Comment

-

TooManyToys

TooManyToys

There is always a different way .....

You did a good job on the videos and the work in it. For the uninitiated they should have no issue after reviewing them. I was throwing some items out for others information.

My (our) experience with options 1 and 2 was the folding of the sleeve never gave a good solid crimp like the full barrel. With the full barrel even the worst of the guys still had a good connection. I also still apply a light amount of solder to a crimped connection rather then worry about an oxidation issue later on.

For the Posi-Locks we used them under the hood as well as connecting to ABS wheel sensors to acquire wheel speed. They were quite good ..... but if it was a long term test vehicle, the Posi was replaced with a soldered, wrapped joint. We just could not take the chance of bad test data. Behind a dash I've had no problem in considering them as permanent.

If I was splicing into the harness like the videos the only thing I would do differently is not use the wire ties and the overall shrink tube. I would use non-adhesive harness tape (often on eBay) and wrap the bundle with the ends tied off. It would permit the bundle to bend a little better, although it takes some skill to do that well.

But well done, Jim. Very well done.Comment

Comment