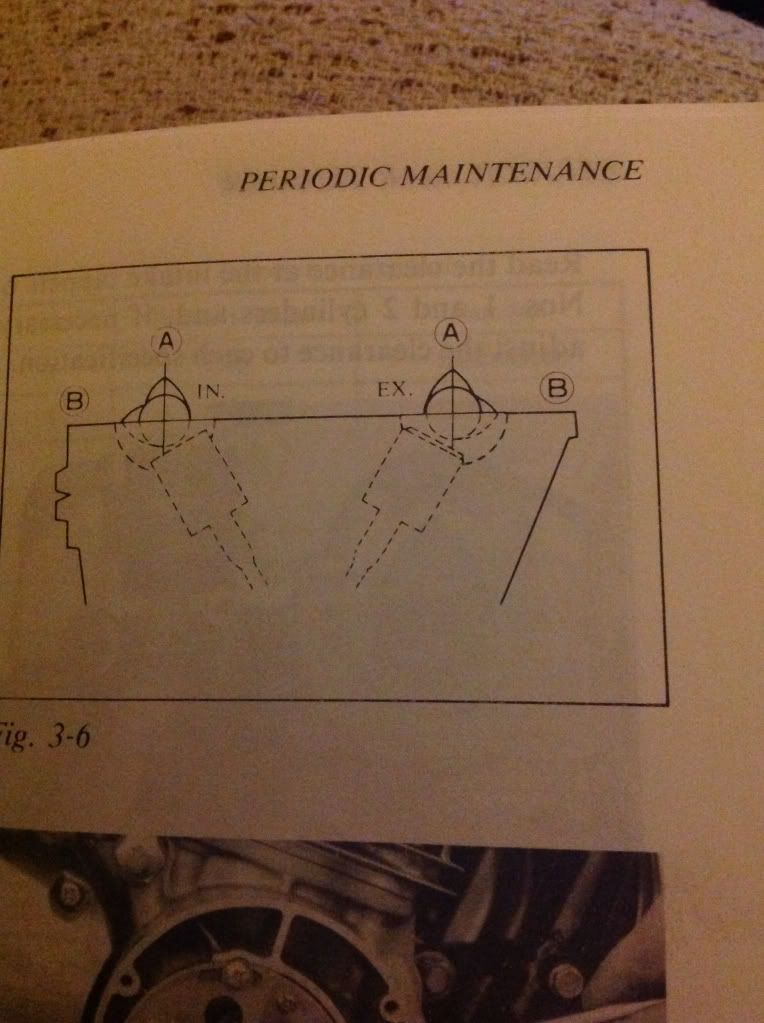

What I would like to know is is the method shown in my Haynes manual the acceptable method for working out the shim sizes required. It stares to select the correct size shim thickness required, subtract 0.03mm from the measured clearance on the fitted shim then add this figure to the size of the shim fitted to the bike, then select the largest available shim whose thickness is slightly smaller than the final figure

hope it's easier in practise.

hope it's easier in practise.I don't have any spare shims at the moment, but if after measuring all inlet/exhaust I find I can swap a few existing ones around what can be used to act as a shim while rotating the engine, read on here someone had used a coin as a substitute shim, appreciate any information.

Comment