Thanks,

Clutch Nut

Collapse

X

-

Clutch Nut

What's everyone do to told the inner and outer baskets so the clutch nut can be tightened? I tried a home made tool, but its not stout enough.

Thanks,Tags: None -

p_s

p_s

If the engine is in the bike, you can put the bike in gear and step on the brake pedal.

I can't remember how I did it with the engine out. I think I used the countershaft nut on the front sprocket. -

Impact gun...

Put a work glove on, grab the hub and Zing! its tight... Bob T. ~~ Play the GSR weekly photo game: Pic of Week Game

Bob T. ~~ Play the GSR weekly photo game: Pic of Week Game

'83 GS1100E ~ '24 Triumph Speed 400 ~ '01 TRIUMPH TT600 ~ '67 HONDA CUBComment

-

Guest

Guest -

rcp

rcp

If you've got a Haynes shop manual, grab that and read it rather than the following paraphrase:

You can also build a clutch holder out of a couple of flat bars of 1/8" steel: bend two L finger-ends in the bars, drill a hole in the middle of both, and hinge them (like a pair of pliers) with a bolt through the holes. This is a poor description, but the idea is a shop-made version of these:

- RichardComment

-

sharpy

sharpy -

CCMcC

CCMcC

The charm

I made a similar tool using rebar and an old clutch plate. A friend welded it together (bless him). It worked beautifully!Comment

-

Wingnut1

Wingnut1

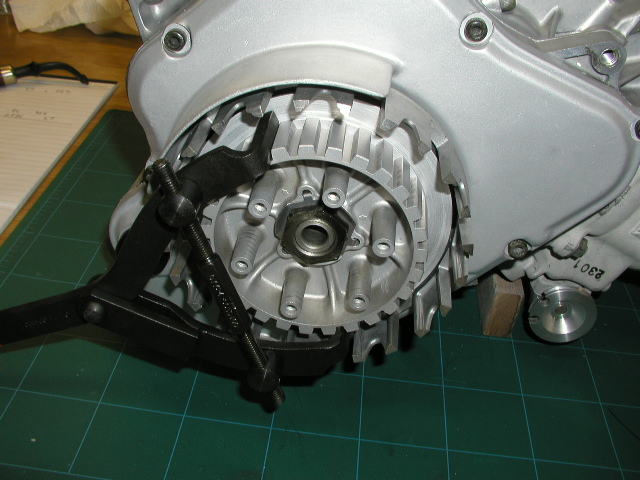

Sharpy, Thanks, Here's mine, it worked great. I used 3 plates to distribute the load, but yours is prettier.

I had read the Haynes manual and made 2 L brackets of 1/8" x 1 1/4 " flat bar stock, but even if they were bolted together, they would have needed to be spread.

Comment

-

Wingnut1

Wingnut1

Comment