What happens is that at idle the guage is relatively stable, but as the engine revs up the guage starts to bounce. I put a scope on the sensor and found that the ignition noise causes bounce and the guage is very responsive to the noise. From the factory the gages had oil in them but they seem to loose that and so you get bounce. Except for the noise they are still accurate so if you can average through the noise no issues

I did check to see if it was vibration induced and it is not. You do this by simply grounding the temp sensor wire and the bounce mostly goes away. But at low temp where there is highest resistance at the sensor the bounce is high.

I have considered electronic filtering and that may be an alternative if I cant get any oil into it. So any body done this successfully? The only opening for getting oil back in is the small space between the shaft and the plastic housing the rotor spins inside. I'm worried about filling with l as if it leaks out it will make a mess.

Please note this is an Air Core gauge and not the Thermal Bimetalic spring type that came on earlier models.

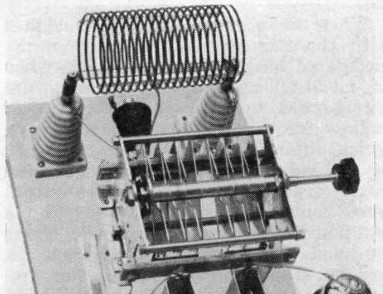

I did find this link using google where an old Corvette guage is improved using oil injection. Unfortunately you can see the back of the guage it is completely covered in wire windings

Some points on “damping” in the gauges - Jason Oliver

The way the dampening is done inside the gauges, fuel and

battery/ammeter especially, is in the air core movement itself.

The way I “fix” this is to inject a non-hardening grease/gel into the air

core movement and it slows the needle “bounce” down quite a bit

without messing with calibration.

There are 2 problems and the 63/64s are worse than others. One is

that the sending units are "bouncy“. Surely someone has a picture of

one taken apart to show how they work. Then, the 63-64 gauges

(fuel and battery) are touchy. The gel I use is injected into the

needle shaft and it helps a lot on the jumpy gauges. This is a GM fix

that has been around for awhile; just not well advertised...same

principle as liquid filled gauges (helps dampen needle bounce).

.png)

Comment