This is the progress so far.

I decided to pull the cams again and lop the ends off the #1 cyl end of the cams. Too hard to degree them otherwise.

The pictures tell the story.

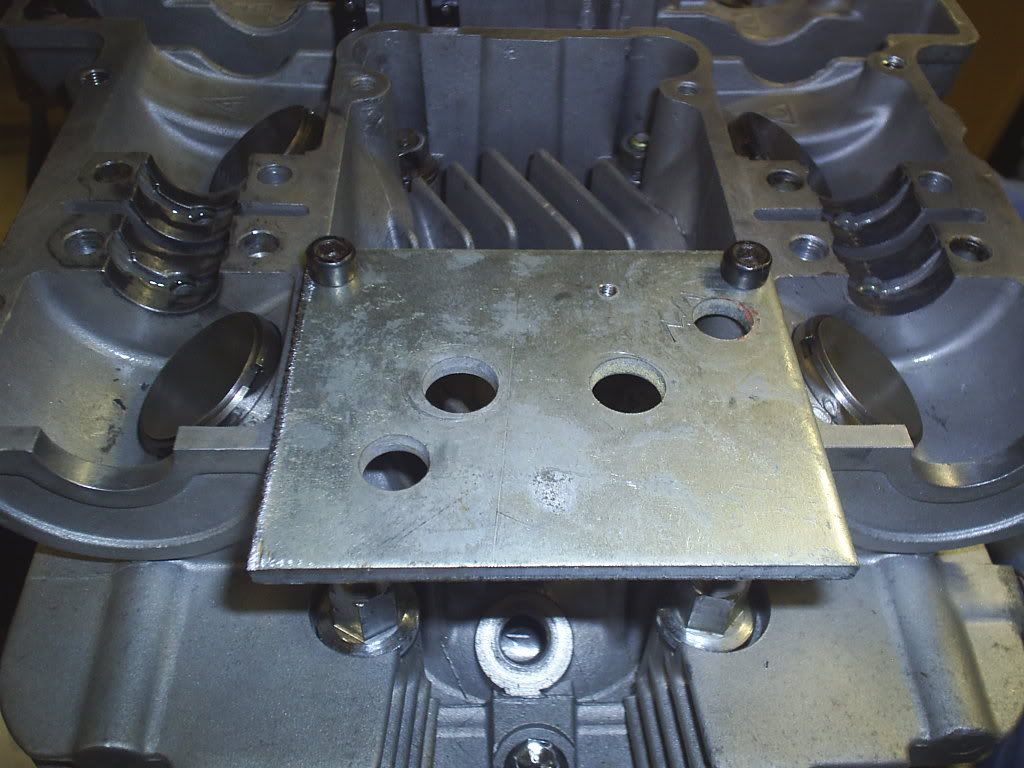

The plate I made up to mount the magnetic dial gauge base to. Turned out to be very solid and did the job very well.

Didn't have a chop saw so the old hacksaw had to suffice. did the job OK. Only about 10 minutes for each cam.

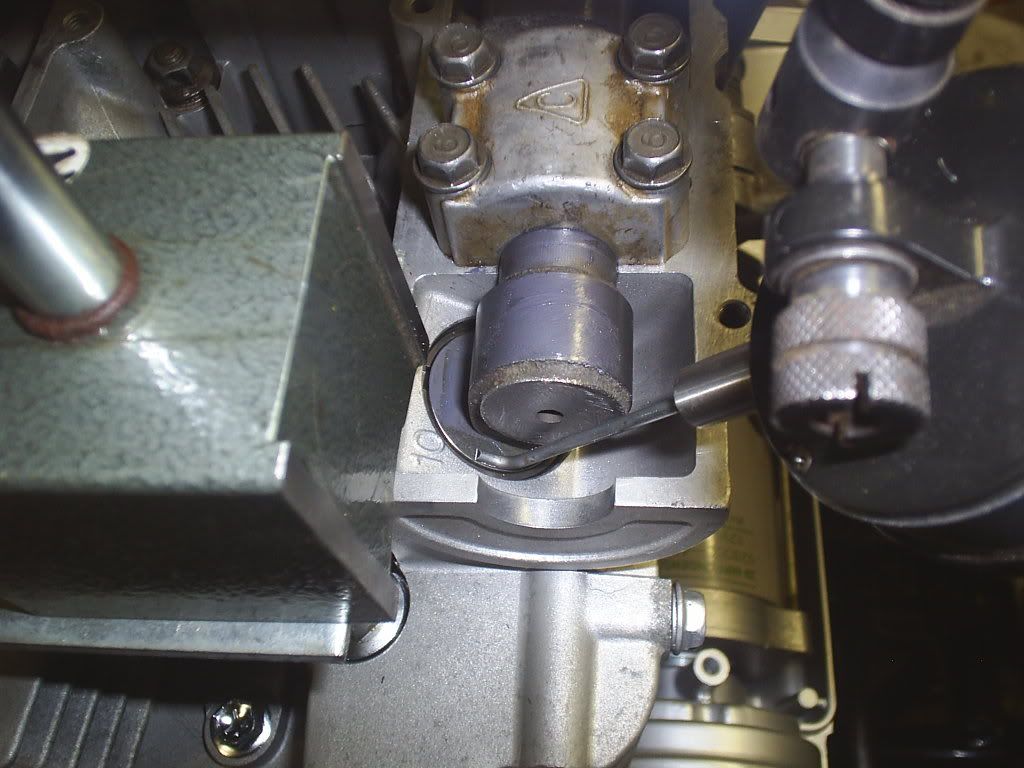

Another close up of cutting process.

End result after end had been cut off the camshaft.

Cam lobes and bearing surface being lubed with moly prior to reassembly.

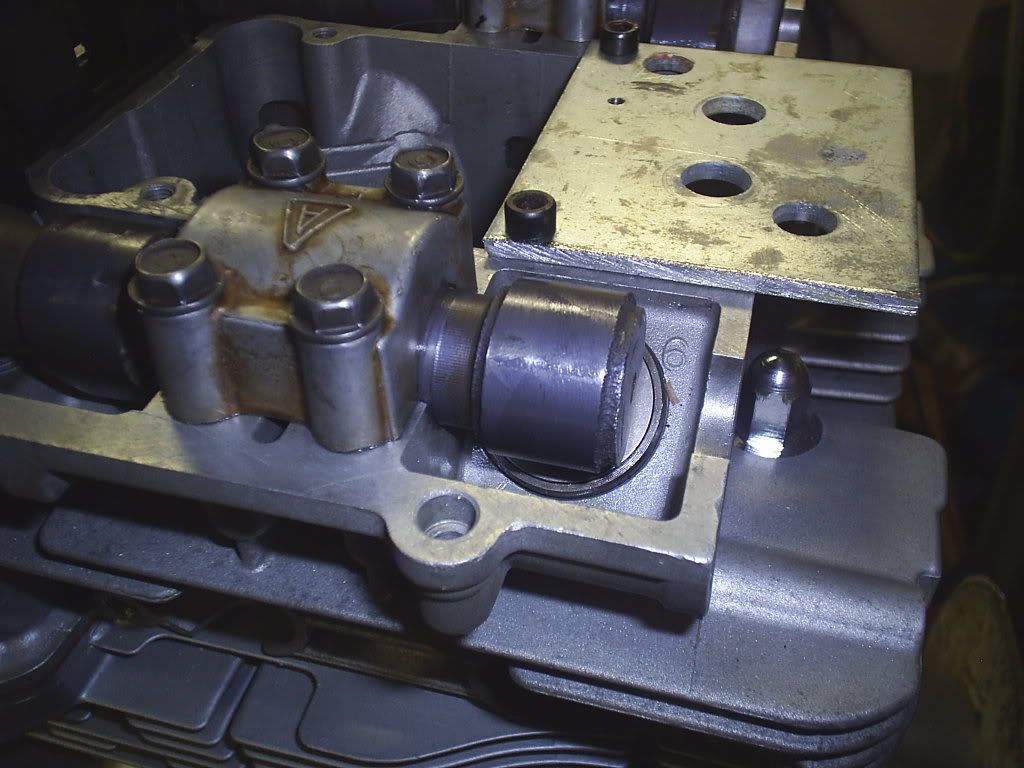

Cam reinstalled with greater distance between the end of cam and where the half moon seal goes.

This pic shows the other end of cam with smaller clearance with half moon seal area for comparison.

The end result shows plenty of room for the dial gauge probe to fit on bucket/shim.

SEE QUESTION NEXT POST !!!!!!!

Comment