Announcement

Collapse

No announcement yet.

Potential Group Purchase - Wiseco GS650 741cc pistons

Collapse

X

-

Guest repliedI want to head and ordered a new one. I got it for $86. Those are not casting flowmarks. They actually go down into the aluminum. And they run from one bearing to the other. I guess if you guys think that it's good enough to run I will always have an extra just in case I mess up again. Ha ha ha thanks a lot for all the advice though guys. It's nice to know that there's a group of people out there that have my back.

Guest repliedI want to head and ordered a new one. I got it for $86. Those are not casting flowmarks. They actually go down into the aluminum. And they run from one bearing to the other. I guess if you guys think that it's good enough to run I will always have an extra just in case I mess up again. Ha ha ha thanks a lot for all the advice though guys. It's nice to know that there's a group of people out there that have my back.

-

I'd run that engine. The bearing saddles just hold the bearing races in place. Pretty sure that missing material won't matter.

Leave a comment:

-

That's very surprising, I had to grind away a ton of metal. What year 550 cases did you use?Originally posted by Old Colt View Post

On my engine case the 650 cylinders fit, tightly but they fit the 550 case. I did clean up some casting flash a bit so the cylinders set down easier is all mine needed.

Leave a comment:

-

Since it's a roller bearing engine I would agree it's OK, I might be concerned if it was going to be a highly stressed engine abused in racing or something but I bet for normal use it will be OK. Hell it's probably OK anyway, the 550s are extremely overbuilt, as indestructible as any engine ever made.

Leave a comment:

-

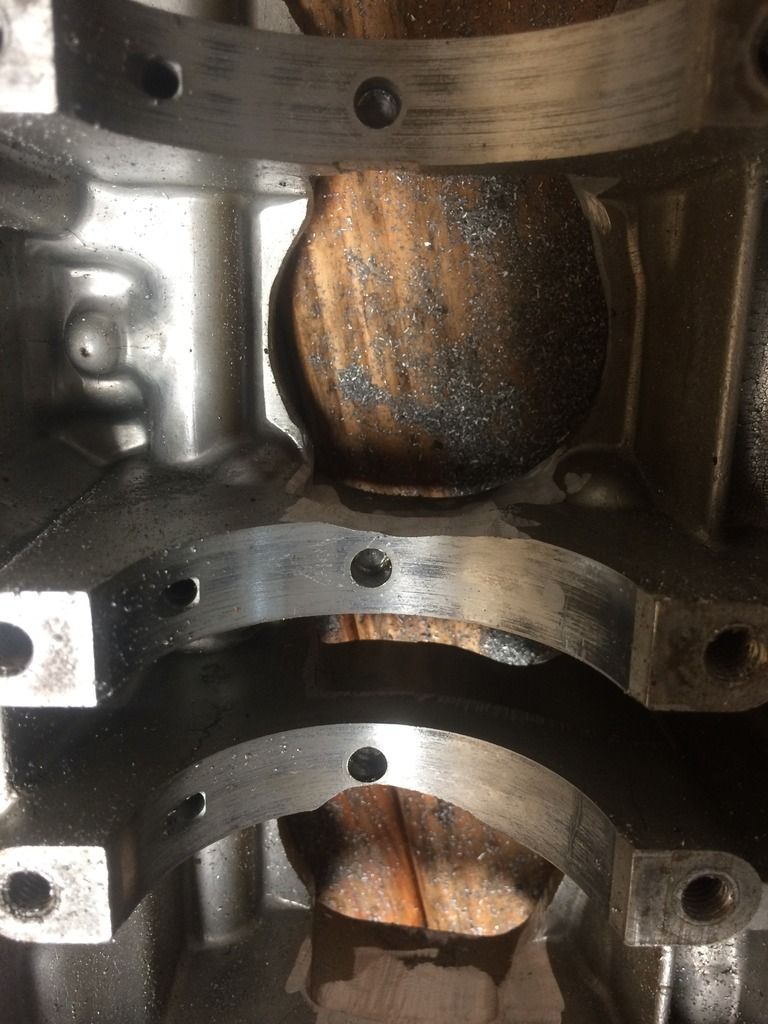

What he said. Grinding the bearing saddle down like that, I'd be a little concerned about however. That's pretty deep on one and looks like you cut into the side all the way to the bearing on another.Originally posted by Old Colt View PostThat will not hurt the engine. The lines you point to are casting flow, not cracks. You did grind one bearing saddle in pretty deep though.

Doing this type of work you are much better off to do trial assemblies and let the parts talk as to what is needed to be done. The areas you ground, neither the pistons nor the cylinders go there.

On my engine case the 650 cylinders fit, tightly but they fit the 550 case. I did clean up some casting flash a bit so the cylinders set down easier is all mine needed.

The "cracks" are just casting lines as said. Not cracks at all.Last edited by Chuck78; 07-03-2016, 09:24 AM.

Leave a comment:

-

Guest repliedThat will not hurt the engine. The lines you point to are casting flow, not cracks. You did grind one bearing saddle in pretty deep though.

Guest repliedThat will not hurt the engine. The lines you point to are casting flow, not cracks. You did grind one bearing saddle in pretty deep though.

Doing this type of work you are much better off to do trial assemblies and let the parts talk as to what is needed to be done. The areas you ground, neither the pistons nor the cylinders go there.

On my engine case the 650 cylinders fit, tightly but they fit the 550 case. I did clean up some casting flash a bit so the cylinders set down easier is all mine needed.

Leave a comment:

-

Click on the image code, paste on the post and this will appear.Originally posted by Ace07 View PostI have never used photo bucket before, but I am sure it is not to hard. I will try to post some pictures. I just can't believe I did something that stupid. It was just one of those days for me

I also found some hair line cracks.

so I will probably just order a different case

Last edited by Charlie G; 06-19-2016, 02:08 AM.

Last edited by Charlie G; 06-19-2016, 02:08 AM.

Leave a comment:

-

Guest repliedI have never used photo bucket before, but I am sure it is not to hard. I will try to post some pictures. I just can't believe I did something that stupid. It was just one of those days for me

Guest repliedI have never used photo bucket before, but I am sure it is not to hard. I will try to post some pictures. I just can't believe I did something that stupid. It was just one of those days for me

I also found some hair line cracks.

so I will probably just order a different caseLast edited by Guest; 06-19-2016, 12:21 AM.

Leave a comment:

-

Post some good photos. Use photobucket or similar and post up the IMG code. Hopefully it's not too bad.

Leave a comment:

-

Guest repliedHey guys I think I messed up on grinding out my top case to make the 650 cyclinders fit. I was dumb enough to grind part of the case where the crank sits. If I found in half way will the case still work? I am such an idiot sometimes. I cut about a quarter into it.

Guest repliedHey guys I think I messed up on grinding out my top case to make the 650 cyclinders fit. I was dumb enough to grind part of the case where the crank sits. If I found in half way will the case still work? I am such an idiot sometimes. I cut about a quarter into it.

Leave a comment:

-

I think it's the opposite. To be able to be sold in places with very hot climates they need enough cooling fins to keep the engines from burning up in the hottest conditions they would encounter anywhere. These GS engines were fine going up steep hills in desert heat, were sold in tropical places for years and I don't recall them ever having problems from getting too hot. Mine were fine in Death Valley in summer, the Arizona desert, stuck in traffic in Phoenix, just never heard of problems from running too hot. The later 16 valve engines got hotter around the heads, some needed oil coolers, but the 8 valve engines were always fine. This gives them way more than enough cooling fins to stay cool in more normal temperatures. I bet if you were to measure the temperatures in more normal operating conditions you would find them quite cool compared to similar water cooled engines.Originally posted by Chuck78 View PostCould be that these air cooled engines that run much hotter (270 degrees vs 210 water cooled) need more quench/squish band height due to different operating parameters? Heat of compression and latent heat combined is what causes detonation (like how a diesel operates intentionally).

I will research this more.

Leave a comment:

-

Guest repliedYeah those prices for those gaskets sound good to me. I have heard anything back from wiseco. I called them Friday and found out my contact, Ale, is gone until Tuesday. I always hate waiting. Ha ha ha

Guest repliedYeah those prices for those gaskets sound good to me. I have heard anything back from wiseco. I called them Friday and found out my contact, Ale, is gone until Tuesday. I always hate waiting. Ha ha ha

Leave a comment:

-

Guest repliedThe engines I build which are considerably smaller than that old big iron are run considerably tighter clearance. Common practice is around 0.030 clearance. Most of my engines are in the 0.015 to .020 range.

Guest repliedThe engines I build which are considerably smaller than that old big iron are run considerably tighter clearance. Common practice is around 0.030 clearance. Most of my engines are in the 0.015 to .020 range.

With this piston setup the clearance up in the chamber needs to be checked as well as the outer squish area.

Those prices are good. Obviously there are other costs involved such as shipping in and out.

Leave a comment:

-

Here ya go!

I recall the gs750/850-920cc I built a few years ago having the piston about .016" in the hole @ TDC after a very light skimming of the block deck surface to mill it smooth. I was told that the GS1100G MLS gasket I was using had a compressed thickness of .040", and that would put me at an ideal quench height to help ward off any detonation (pre-ignition/"pinging").Originally posted by John @ GasketsToGo.comHi Chuck,

Cost to make your gasket as a 1.3 or 1.4mm MLS head gasket would be as follows:

1-4 pcs: $119.95/ea.

5+ pcs: $79.95/ea.

Lead time is 3-4 weeks at the moment.

We can work from a scale scan you make (more info: www.gasketstogo.com/scans)

Or you can send your pattern to me (www.gasketstogo.com/mailing)

If you decide to order I would send you a PayPal invoice you can pay by credit card once we are ready to proceed.

I will attach an info sheet for MLS gaskets to this message.

Regards,

John

--

Regards,

John M. Baker

Owner

In my hot rod/musclecar days with my GTO fanatic dad, I had learned in that community that in a water cooled small block chevy v8, .039"-.045" quench height was preferred to keep you clear of detonation concerns. Could be that these air cooled engines that run much hotter (270 degrees vs 210 water cooled) need more quench/squish band height due to different operating parameters? Heat of compression and latent heat combined is what causes detonation (like how a diesel operates intentionally).

I will research this more.

Leave a comment:

-

Guest repliedIt would be nice to get a clay imprint between the head and piston just to see what the chamber looks like at TDC and what the true squish is.

Guest repliedIt would be nice to get a clay imprint between the head and piston just to see what the chamber looks like at TDC and what the true squish is.

At an estimate of $80 for Cometic the Gaskets to go might be very competitive, might be damn nice gaskets too and for me much less work than making an O-ringed copper gasket.

I am thinking I should get my azz in gear and assemble the bottom end of this motor. I am thinking I am glad I never contoured the chambers to fit the OEM 750 pistons.

Leave a comment:

.png)

Leave a comment: