My cylinders are bored and waiting for my pickup at the machine shop now, however I am frantically trying to get my GS750 ready for a cross country trip and trying to dodge the rain coming through. I will be returning May 21st Sunday evening. Hope to have my wife pick up the 650 cylinders Monday May 22nd.

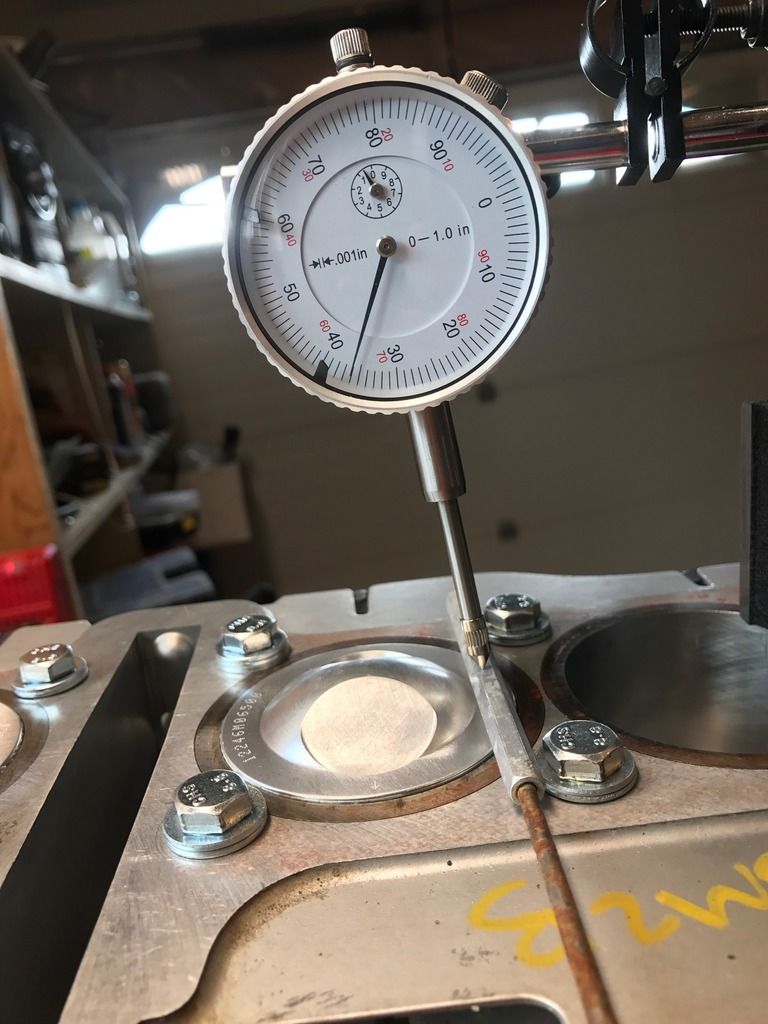

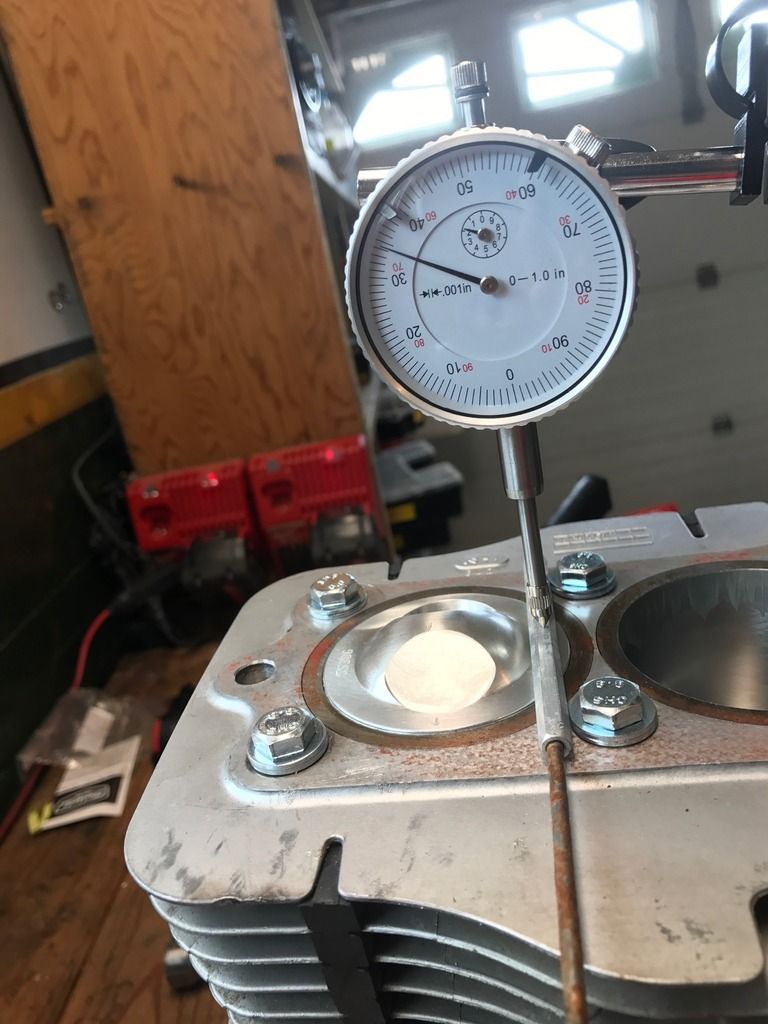

If anyone else has their cases clearanced, cylinders bored, and ready to do a mockup for deck height with or without a stock base gasket in there, please do. This is the main thing we are waiting on. If any of you can get a definitive answer on deck heights, more than one would be best (and nice to know if it is likely if your block is stock deck height or if it has been milled before), please let me know. I have all but one member's gasket funds in my paypal account awaiting to be invoiced once we tell John what thickness we need.

I am really thinking we should go with custom 0.8mm base gaskets from Gaskets To Go as well, and then 0.1mm thicker than an OEM gasket compressed for the head gasket, so I believe that would be 1.2mm or 1.3mm. That leaves a little room for milling the block, but not much. 0.8mm base and stock head gasket thickness is the bare minimum for ultimate quench distance on a factory deck height, i.e. never resurfaced aka milled.

There is no .9mm base gasket material available, and I am not sure if the next step up was 1.0mm or 1.2mm base gasket.

I feel comfortable ordering .1 or .2mm thicker than stock, as we can resurface the block more to dial in the squish band / quench height. should be fine running .1mm thicker than stock on an un-decked block as well, but max efficiency and power is to be had at .8mm base and stock head gasket thickness. That supposedly equates to around .038" quench from Suzuki_Don and Sci85's builds.

Also I have not been able to send John a GS650 gasket as a template. Can anyone else here volunteer their time to send one in to him? If you have an unused OEM gasket, that would be preferred, as they have some sort of rubber coating at the cam chain tunnel area to enhance the sealing. I am not sure if John can do this or not, but it would be nice to illustrate that to him firsthand rather than trying to describe it over email. If anyone wanted to just use the stock 650 base gasket, you can simply go 0.3mm or 0.4mm thicker than stock on the head gasket and your deck height will be the same. You will just lose a slight bit of compression due to greater gasket opening volumetric area from the increased thickness.

Let me know if anyone can do these things faster than i can make time to get to them.

Thanks,

Chuck

.png)

its been too long of a weekend. So what you are saying is that if we order a 1.3mm head gasket it will compress to 1.2mm?

its been too long of a weekend. So what you are saying is that if we order a 1.3mm head gasket it will compress to 1.2mm?

Comment