Announcement

Collapse

No announcement yet.

Potential Group Purchase - Wiseco GS650 741cc pistons

Collapse

X

-

Guest repliedHow doesn't surfacing the head affect squish band? If you take material off the surface of the head it will move the pistons closer to the head chamber. How is it different than surfacing the cylinders?

Guest repliedHow doesn't surfacing the head affect squish band? If you take material off the surface of the head it will move the pistons closer to the head chamber. How is it different than surfacing the cylinders?

-

If you want to build more compression by not losing it with head gasket bore volume (thicker head gasket, gasket bore is larger than our 65mm cylinder bore), then it **might** be a better idea to run a 1.3mm head gasket and add .3mm to the base gasket thickness.

That would give you the same quench height as stock OEM base + 1.6mm ordered / 1.5mm compressed head gasket.

I am really needing to get this Wiseco 610cc GS550 rebuilt and out of my shop space so I can tear into the 77 550 donor engine and measure my deck height!!! Almost there... I want to get the block skimmed more than .003" just in case, which is about all I'd skim yours Andy if you order the 1.6mm head gasket.

.1mm head gasket thickness additional means .1mm or about .004" to skim off the block if mine is the same as Andy's block height and installed deck height.

So If those were my measurements, I'd go 1.7mm (stock base gasket or equivalent head gasket using .8mm base) so that I could have .040" quench distance and be able to mill .007" off the top of the block deck if necessary.

Thoughts????

Leave a comment:

-

.006" off of the head does not affect the squish band at all. it only affects cam timing and piston to valve clearance.Originally posted by Ace07 View PostSo for me. If I was to get the stock base gasket thickness which compresses to .019", and I was shooting for .04" for a squish band.

Then, I would originally needed a head gasket that would compress to .057", but I had .006" taken off the head to smooth it. In the end, I would need:

A head gasket that compresses to .063" and a stock base gasket that compresses to .019".

Does that sound right?

So, Andy has:

Deck height = +.036" max (piston out of hole, no base gasket, bock torqued)

wants approximately .040" squish band quench height with gaskets compressed

stock base gasket compressed = .019"

.036" - .019" = .017"

.017" + .040" = .057"

.057" x 25.4 = 1.4478mm compressed (1.45mm)

1.45mm compressed head gasket = order a 1.55mm head gasket.

they come in in 0.1mm increments. So you're either going to have a 1.4mm/.055" compressed (1.5mm ordered) head gasket,, or a 1.5mm/.059" compressor (1.6mm ordered) head gasket.

.055" - .017" = .038" squish band

.059" - .017" = .042" squish band

how tight are your crank bearings (mileage on engine? Well cared for? I often measure cam chain stretch to determine how cared for an engine is. Measure the crank bearing tolerances (rod big end / crank pin being the most critical - fastest wearing on these long life roller cranks)

Either would work in a tight engine. 1.5mm compressed (1.6mm ordered) giving you .042" squish band is still a great number, but not the ultimate ultimate race bike maximum performance seeking quench, but rather a nice but minimal safety margin.Last edited by Chuck78; 11-27-2017, 10:00 PM.

Leave a comment:

-

Guest repliedYeah sorry about the first attempt. It was sloppy. I was not in the right mind set last weekend.

Guest repliedYeah sorry about the first attempt. It was sloppy. I was not in the right mind set last weekend.

I did not use any calipers this time.

Yes all my measurements were taken without a base gasket, and as far as I know nothing has been done to the cylinders.

In terms of the bolt, I know I was about 3/4" engaged threads. I went to the local hardware store and bought new bolts for measuring the deck height. I also tried to find some aluminum washers, but they didn't have any.

So for me. If I was to get the stock base gasket thickness which compresses to .019", and I was shooting for .04" for a squish band. Then, I would originally needed a head gasket that would compress to .057", but I had .006" taken off the head to smooth it. In the end, I would need:

A head gasket that compresses to .063" and a stock base gasket that compresses to .019".

Does that sound right?

Leave a comment:

-

So about .036" max with NO BASE GASKET??? This is more what I was expecting based on Suzuki_Don & Sci85 550-650 builds. They needed .3mm more deck height to use stock 650 head gasket

Did you compare this method using a caliper at the wrist pin axis of the pistons? Evenly torqued is much better to ease my mind vs your 1st attempt! I like the one stud method plus 1/2" copper pipe as spacers as a torquing method though, bolts won't be 100% full thread engagement unless you get them long and measure and cut them down very precisely.

Aluminum or brass washers on deck surface would be very nice on the 4 corner studs if not planning to have block milled.

I'm trying to get this gs550-610cc out if my shop this week to make the owner happy and get on to my dirt bike/gs550 projects FINALLY.

Ready to order head gaskets after some calculations and emails to all of you (no one has been replying here...)

I'll crunch some numbers tomorrow. Bedtime here.Last edited by Chuck78; 06-16-2017, 06:15 AM.

Leave a comment:

-

Guest repliedHey Guys,

Guest repliedHey Guys,

I went ahead and ordered a feeler gauge off of amazon, and received it last Wednesday. Today was the first time I got a chance to take any measurements on the decking. I will go ahead and say that the first measurements I took were not very good, because I took them with a set of calipers. The measurements I took with the Feeler gauge came out alot more consistent. Hey Chuck, please take a look and see if these measurements seem a bit more realistic.

To start off I went ahead and bought bolts to torque the cylinder down completely.

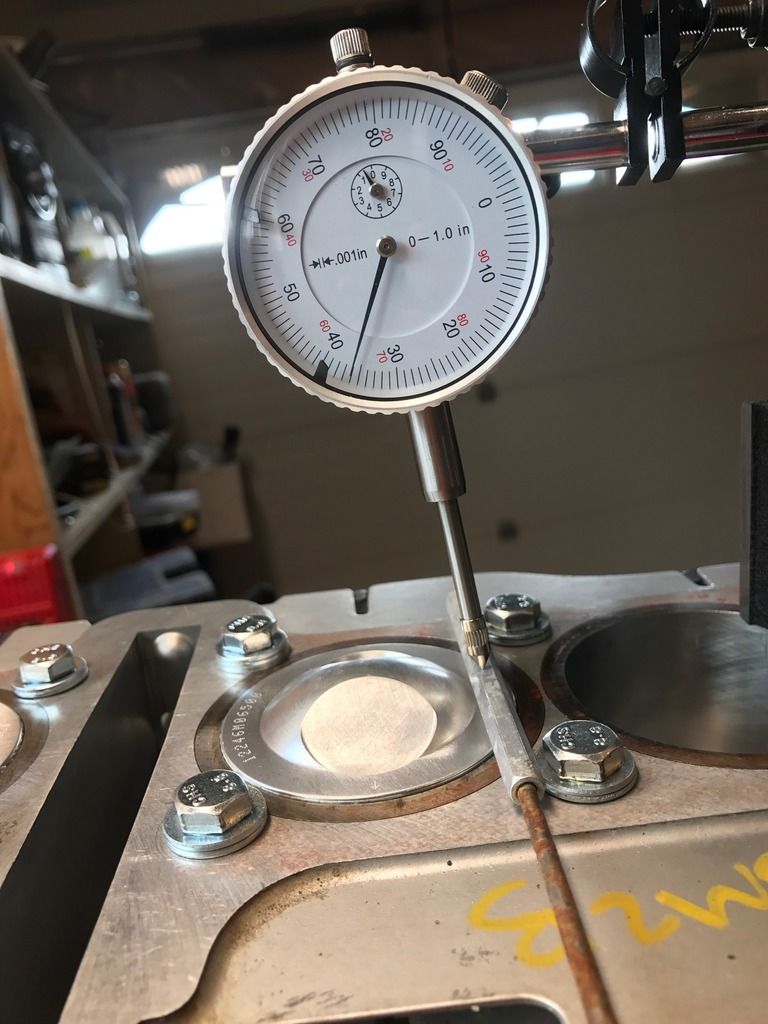

Here is the deck height measurement for piston 1. It looks to be about .035" for a deck height

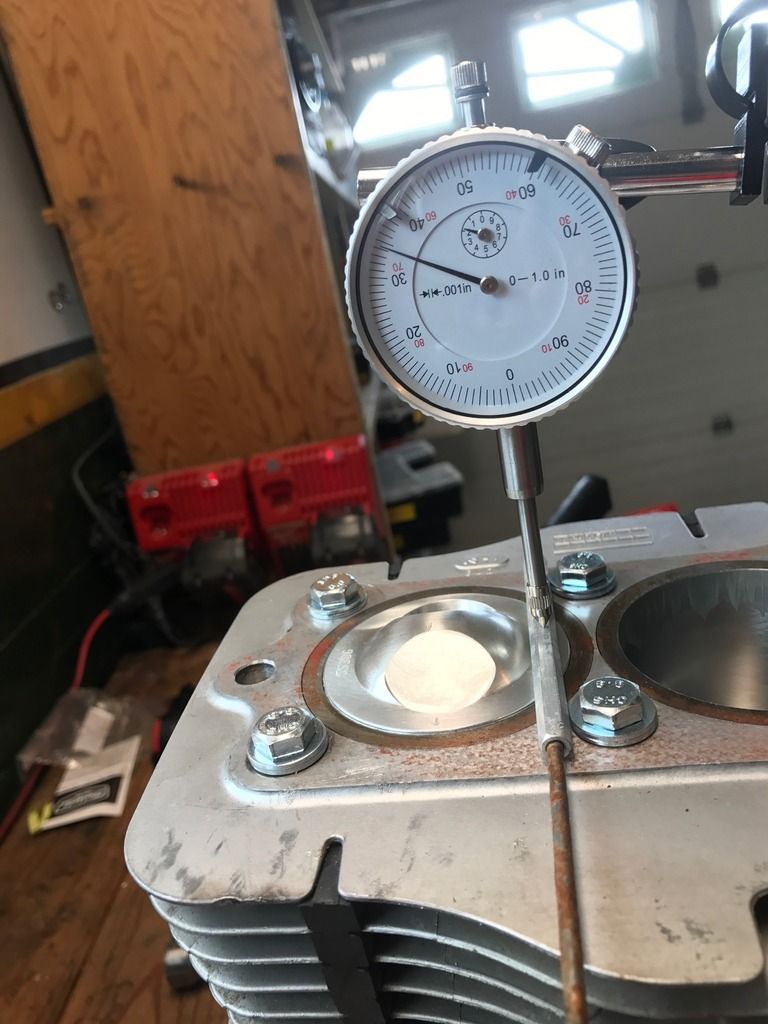

Here is the deck height measurement for piston 2. It looks to be about .036".

Here is the deck height measurement for piston 3. It appears to be about .034".

Here is the deck height measurement for piston 4. It appears to be between .034" and .035".

The thing that the feeler gauge is sitting on is the handle of a metal pick. I laid it across the cylinder sleeve to start off, and then raised the piston out of the cylinder. As the piston raised out of the sleeve, the pick handle would lay flat on the piston surface. This allowed me to measure off a surface that is constantly parallel to the piston surface (assuming the sleeve surface and piston surfaces are parallel). this in turn allowed me to measure the vertical distance between the cylinder and the top of the piston when it is at top dead center.

P.S.: to start off I measure the circularity of the pick handle by laying it flat on the cylinder surface and measuring every surface in the same place. It was .001" or less all the way around. Just to be sure I always measured from the same spot on the same surface on every piston.

How does that sound? Does it make sense?

Thanks,

Andy

Leave a comment:

-

Guest repliedI will get some better measurements

Guest repliedI will get some better measurements

Leave a comment:

-

Guest repliedI will probably take and have my cylinders resurfaced, but I have already had .006" taken off of my head. When does a gasket get to thick?

Guest repliedI will probably take and have my cylinders resurfaced, but I have already had .006" taken off of my head. When does a gasket get to thick?

Leave a comment:

-

Guest repliedOh man thanks for checking my math.

Guest repliedOh man thanks for checking my math. its been too long of a weekend. So what you are saying is that if we order a 1.3mm head gasket it will compress to 1.2mm?

its been too long of a weekend. So what you are saying is that if we order a 1.3mm head gasket it will compress to 1.2mm?

Leave a comment:

-

You will be at an average of .038" quench distance. Your highest piston measurement will be at only .034" quench height assuming it will be the same when block is torqued. I would not have only torqued just the 4 corner studs if I were measuring.

We can get stock oem .5mm, or custom .8mm or 1.0mm base gaskets. We can get head gaskets in 1.3mm (~1.2mm compressed, etc), 1.4mm, 1.5mm, 1.6mm, 1.7mm, etc. I think based on this we should order 1.3mm and 1.4mm head gaskets, maybe 1.5mm for those that may need the block decked more. This all depends on individual deck height, but a resurfacing job is a good thing, & a good machinist can take off a very exact amount off the block to help us dial in the quench distance perfectly for our setup. 1.3mm or 1.4mm seems like be a good bet, & if anyone wants to deck their block more than .07mm (or more than .17mm with 1.5mm head gasket), then they can get a .8mm base gasket made as well.

I'm doing carbs and charging system.upgrade on a K610 Wiseco equipped 77 GS550B-610cc run the next 2 evenings or so, & more soon on that bike for a good friend, but now I am able to get these cylinders mocked up so I can clearance the 550 cases and build my first 740 engine. Should be able to get my own measurements here shortly.

I FINALLY was able to get my more recently acquired rust-seized junkyard 650 cylinders back from the part time / semi-retired hot rod / race engine builder & machinist Bobb Jacobs Friday with the help of a friend. 9-3 shop hours don't work well with my day job! Nice job boring though. He actually chamfered the bottom of the sleeve for me! Most automotive machine shops here don't do that even if I tell them to!

Leave a comment:

-

Guest repliedHey Chuck,

Guest repliedHey Chuck,

Sorry about the late reply, I have been working on a lot of other projects. The way I measured the deck height is by torquing down the 4 corner bolts to 20 ft-lbs, which is what the head is normally torqued too. Then I took several different measurement of the distance between the top of the flat part of the piston, and top of the cylinder sleeve. Most of the measurements I got were .027". With that being said, my total range was from .0265"-.031 thousands. The .031" only showed up in two spots consistently.

To measure the distances I was only using a set of calipers. If we need to be exact, then I will need to buy a feeler gauge and do some really fine measurements. How important is this distance? Is +/-.002" ok, or is +/-.004" ok? I just need to know what kind of tolerances I would need to deal with.

I did my own calculation for my gaskets and here is what I came up with:

With a stock base gasket thickness of (.019" when compressed), .028" for the distance the pistons are above the cylinder without any gaskets, and shooting for a squishband of .04", I would need a base gasket that is 1.24mm (.049") thick when it is compressed. Since I should have plenty of distance before I got to the minimum .035" squishband, I would just go with a 1.2mm head gasket when it is compressed.

Like I said, I am not sure how much a couple thousands distance change will affect how the engine will run, but with the numbers I just gave you for my calculations, I am confident that with a Stock base gasket, and a 1.2mm head gasket, that should keep me within the range of extreme high performance squishband (.035") and stock squishband (.043") as long as the gasket company can maintain their tolerances.

Leave a comment:

-

Andy, upon a quick examination if your numbers, your deck height is a very slight bit higher than Suzuki_Don and a few others have had. .028" above deck + factory .019" or .020" compressed base gasket = piston .008" above deck, + 1.1mm / .043" compressed factory thickness head gasket = .035" quench height which us the bare minimum and is pushing it with any crank bearing / rod bearing big end crank pin wear in my novice opinion.

to get 1.1mm or .043" compressed, you'd need to order 1.2mm thickness. To get a safer quench height, I'd go 1.3mm thickness on the head gasket.

For some reason based on Suzuki_Don and Sci85 etc's findings, I was thinking we'd need to go a bit thicker than that, but part of that was accounting for resurfacing the block deck.

was your block torqued down to very well cleaned crankcase and block mating surfaces?

perhaps we could do a standard run of 1.3mm gaskets (1.2mm compressed) & then have the option to order 0.8mm (.3mm/.012" thicker than OEM) base gaskets for those that end up decking a slight bit, & option to also order 1.0mm base gaskets (.039" thicker than OEM base gaskets) for those that need to deck more? Those are the next 2 sizes up in base gasket materials that we have to choose from. I'd be leery myself of going as thick as 1mm on a base gasket I am now thinking.

Is everyone still tuned in to this? Can I get some opinions? I'm afraid to make the call completely on my own for an order of 16 gaskets for several of us. Hence why I have been timid toward going ahead and ordering until we have some more hard numbers.

Thoughts, please???? Or more mock up dimensions from you all? I would like to get these ordered soon, & we can do an order as small as 5 for the time being and get the same price each, but it would be nice to nail it all now, & I am sitting on PayPal funds for nearly the whole lot currently. 1.3mm seems the best candidate for now. Old Colt is going racer thin on his for max quench and doing machining of the piston to make up for tall deck height. More measurements from you all would really help.

Thanks,

Chuck

Leave a comment:

-

FYI John said base gaskets take no time to tool up for but MLS head gaskets will take a bit in terms of lead time.

Leave a comment:

-

EXCELLENT INFO ANDY!!!

Many apologies for the long delays since I realized there was a compression height difference between 550 and 650 pistons. I just got back from a mountain riding vacation several states away in Western NC. I have all the gasket money in my PayPal balance still, but am struggling, with riding season garage time upon me (my bike and several friends'), to get the time to clearance the 550 cases to mock this up.

I also want to send John/GasketsToGo.com a 650 base gasket so we can have thicker versions made (.8mm?) instead of 1.6mm (massive) thick head gaskets which would drop compression a bit. I am thinking we will want 1.2mm compressed head gasket with a .8mm compressed base, so order 1.3mm head gaskets to allow for a very slight block decking. I will review Ace Andy's numbers tomorrow and see how they jive with my previous best guesswork. It's way past my bedtime here. Thanks for the patience!

ChuckLast edited by Chuck78; 05-29-2017, 11:10 PM.

Leave a comment:

.png)

Leave a comment: