I have been browsing the forum for some time now and have been extremely impressed with the wealth of knowledge shared by community members. First of all, thank you all for providing this fantastic resource!

My name is Chase, I live in Colorado and am working on a 1980 gs750 that was given to me by my step father. The bike had been sitting in our yard back home for some years.

Project snapshot:

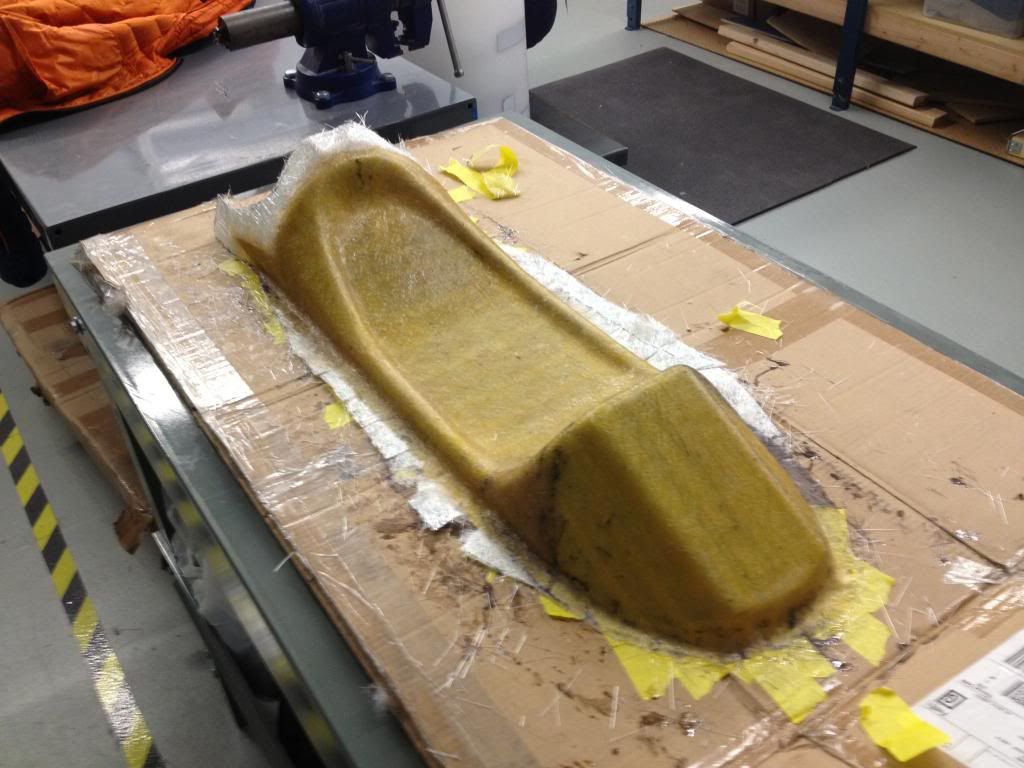

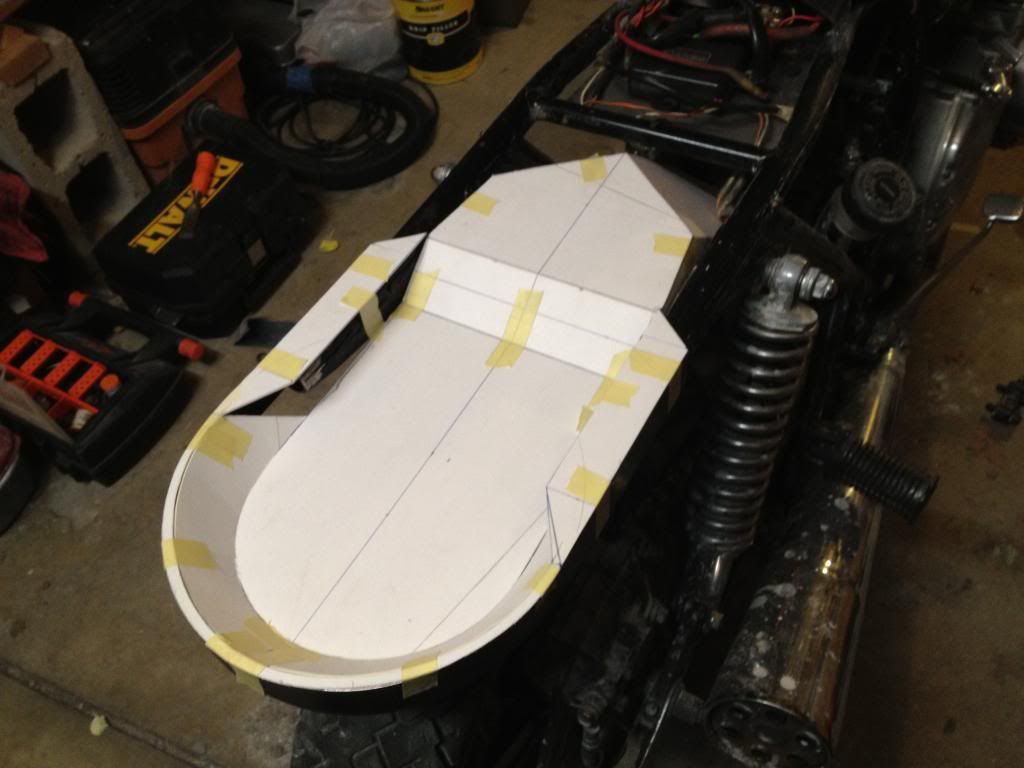

I am making a fiberglass seat pan/rear cowl

Fitted a tank off of a 1980 cb750 super sport

I will be shortening lines and cables

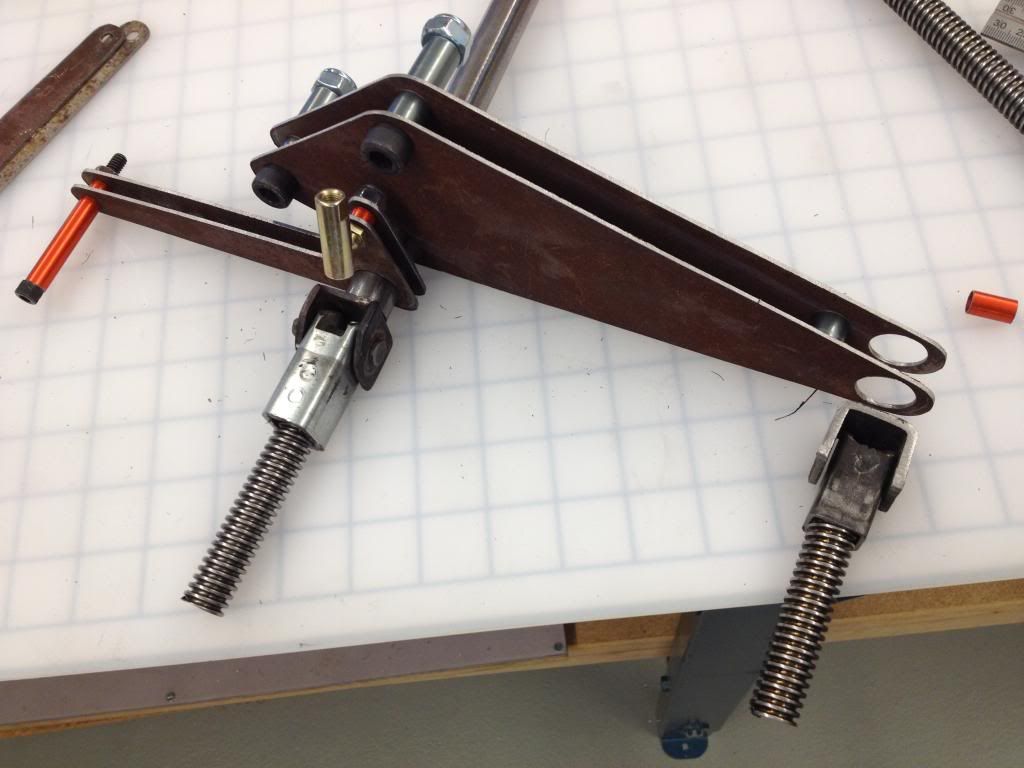

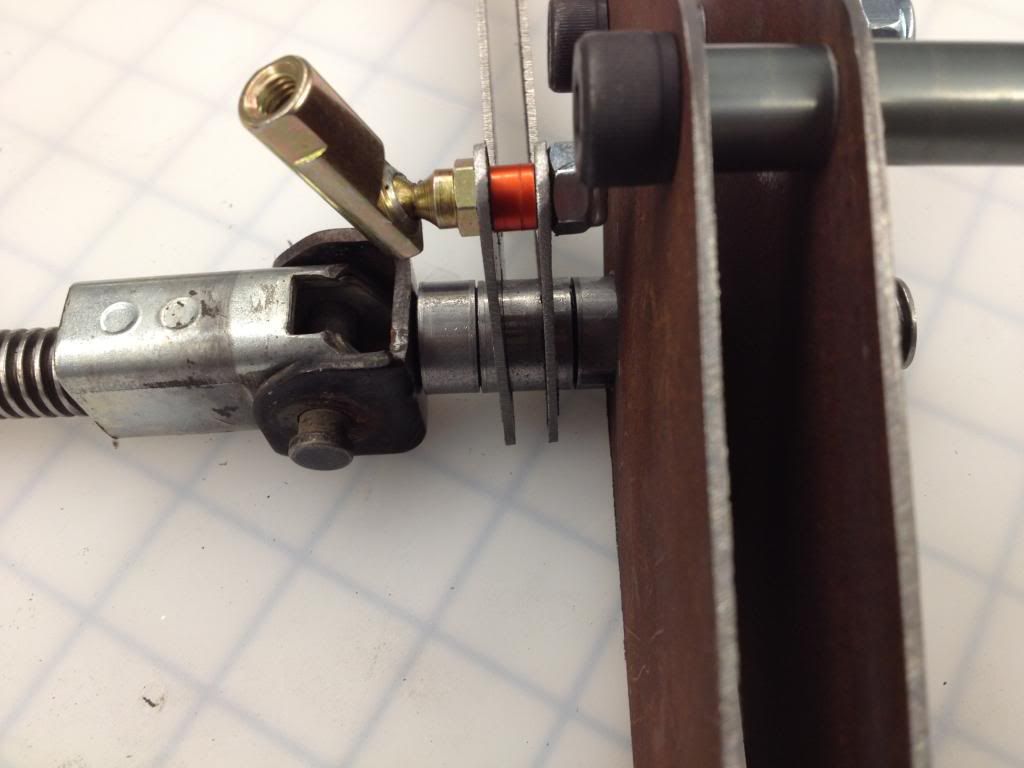

making rear sets

Blending the frame

Painting

Shot of the bike after getting things sorted out

CB750 Tank Fitted

Mockup of the rear cowl

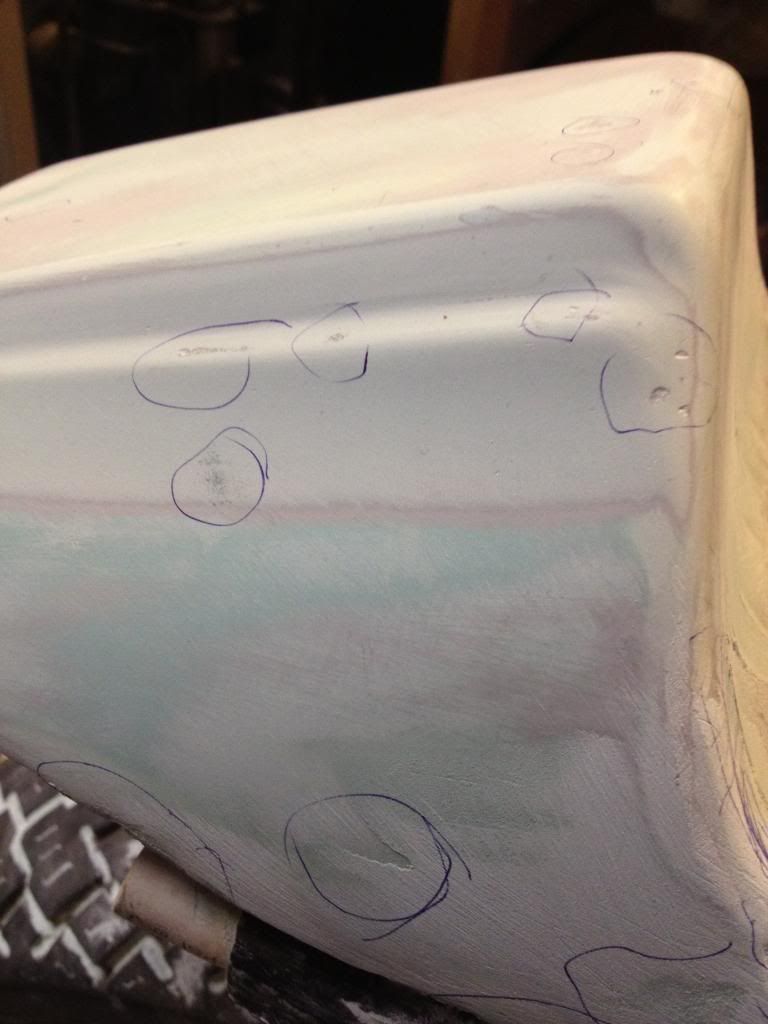

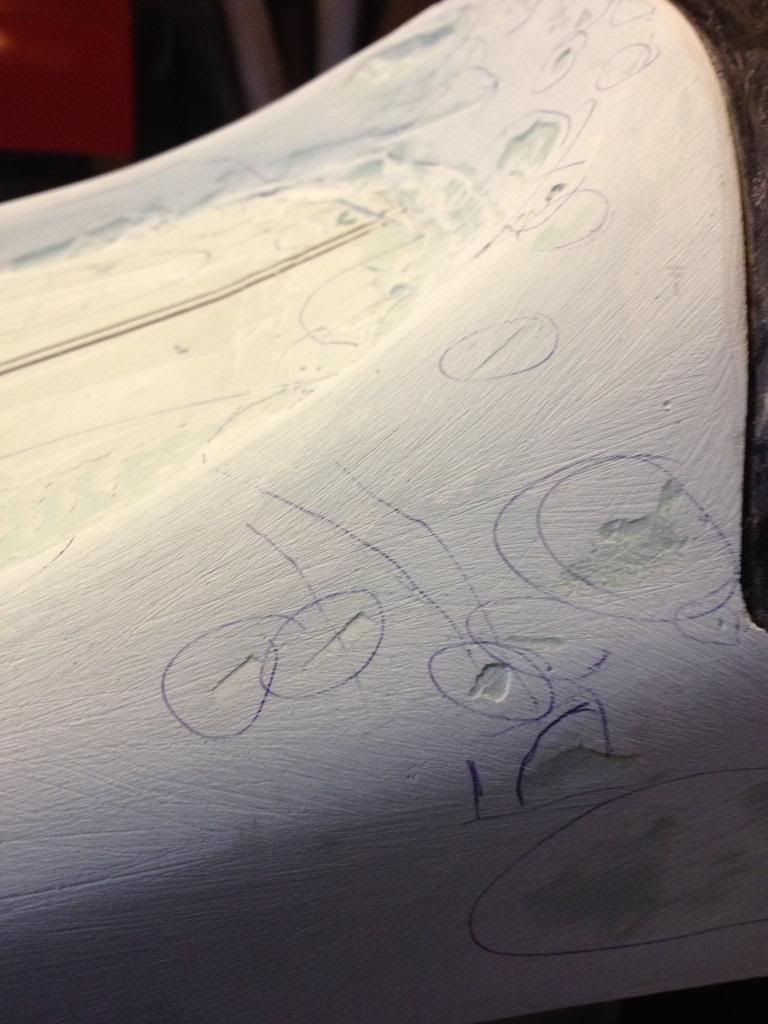

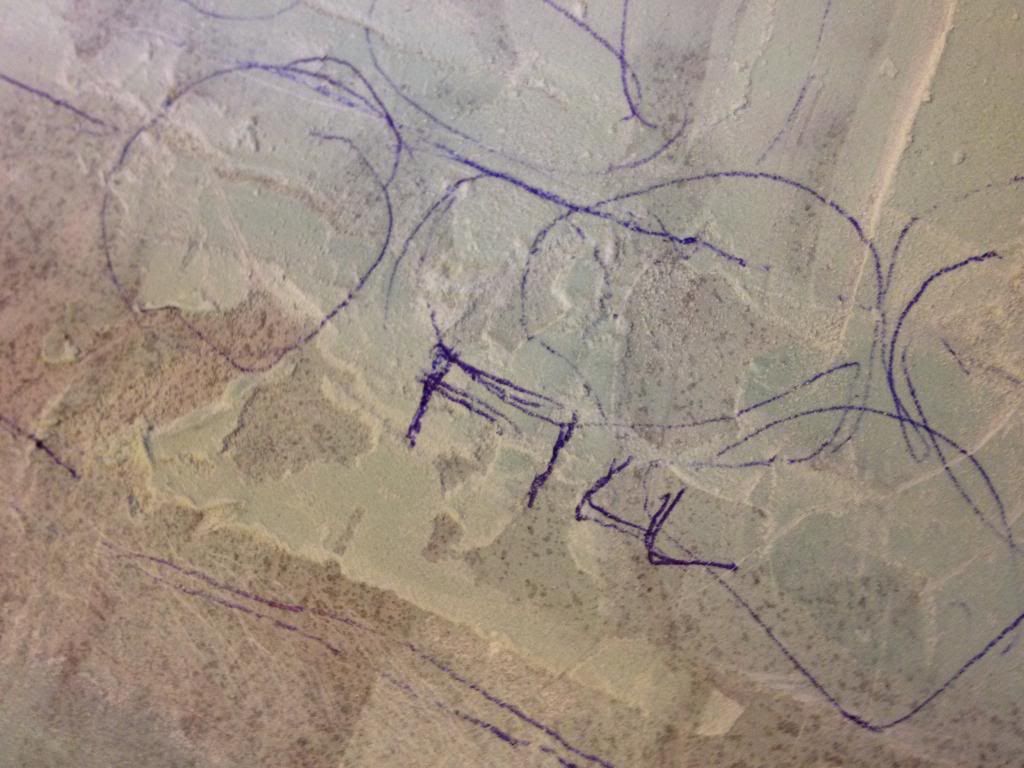

Building up the plug surface

I hope to add pictures to the thread as the project progresses and would love to get feedback/comments. more importantly, I'm looking forward to getting to know all you guys!

Regards,

Chase

Comment