I've primarily followed the advice in this youtube-video:

But first i had to google how to thread the sewing-machine

I tried to find something to draw on vinyl with that would both be clearly visible and easy to remove. Didn't find anything, so I ended up using masking tape.

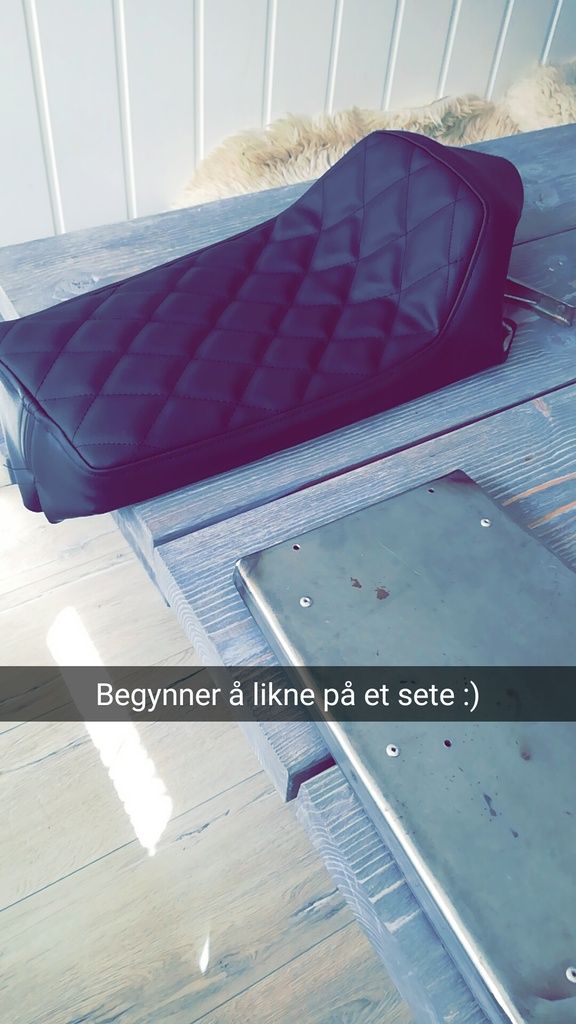

This was the result:

I chose the longest diagonal to be 1.61 times the length of the sides to take advantage of the golden ratio. I've also used the golden ratio to decide the lengt of the seat and cushing in relation to the tank.

Used a large sheet of paper to make a template for the surrounding vinyl:

Sewed the parts together like they show in the video:

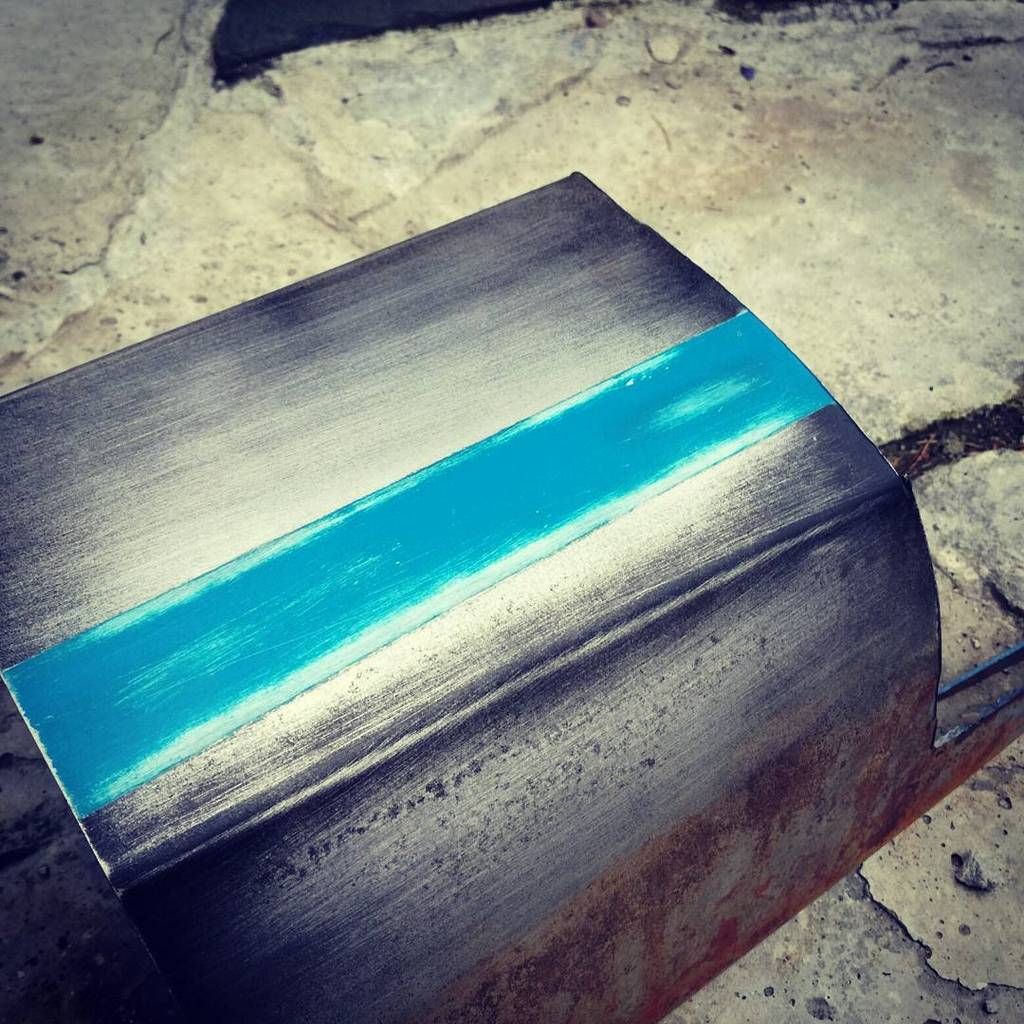

Used spray-glue on the back of the metal and on the inside of the vinyl. Then I stretched the vinyl until the markings lined up. This wan't the smartest way I noticed, as I hadn't been accurate enough with the sewing. I should have flipped it over and lined the vinyl up on the topside av the seat instead. But in the end the result was OK.

Screwed the two pieces together, and this is the result:

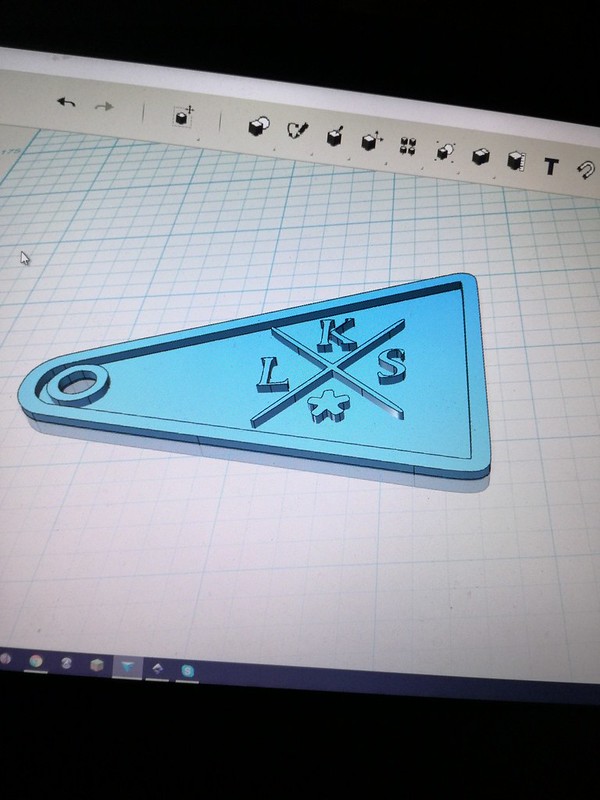

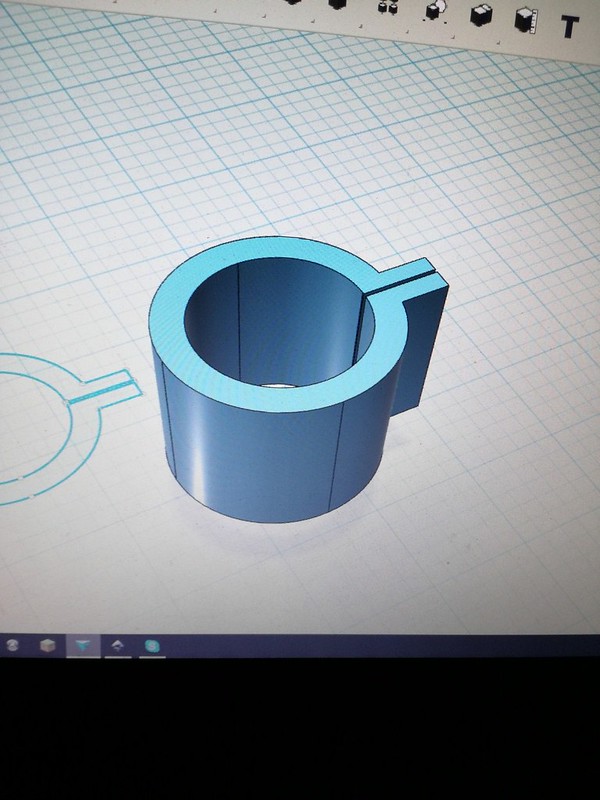

Anyhow, I wanted to test the consept and designed a couple of headlight brackets with my logo on. I found a local guy with a printer through 3dhubs.com and he is printing them in ABS plastic for about 25$. Pretty cool

Anyhow, I wanted to test the consept and designed a couple of headlight brackets with my logo on. I found a local guy with a printer through 3dhubs.com and he is printing them in ABS plastic for about 25$. Pretty cool

Comment