I currently own a 1981 GS550T (aka Shaniqua). I bought it almost 4 years ago and it has been an awesome bike up until 2 years ago. I started having a lot of troubles with it running rough and not wanting to start, so I decided a year ago that I am going to do a complete overhaul on the bike. I started doing research on how to overhaul one of these bikes, and that is how I stumbled across this forum. The further I dug into this forum the more excited I got about doing the overhaul, because I got to read about the different upgrades people have made to their GS bike. One day I came across a thread called “GS550 bored 740 finally done”. It was started by a gentleman named Ryan, in Kansas City, which so happened to be near where I grew up. I read the thread probably 20 times and decided that is what I am going to do to my bike. I emailed him a couple times to get information about the build. I found out that he had turned his GS550 back to stock, because he was having trouble with the engine overheating. To make a long story short, I got the chance to meet him and he sold me the cylinders and head that he used on his 740 build. Now I am going to take a crack at it.

Here is a list of things I am planning on doing to the bike:

1. Bore the engine from 550cc’s to 740cc’s

2. Change out all the seals in the engine

3. Buy a gas tank that has a sending unit in it

4. Completely redo the wiring system and add a micro controller

5. Create a new dashboard with an OLED screen

6. Upgrade the Rectifier to a Compu-fire

7. Upgrade the stator

8. Create a variable oil cooling system

9. Upgrade the front brake to the Salty dual disc setup

10. Upgrade the suspension (not sure how to do this yet)

11. 3-d print a new air box system

12. 3-d print a new storage compartment for under the seat

I have been working on the bike for about 4 months now and here is what I have done so far:

1. Bought the 650 big bore kit from wisco

2. Strip the bike down completely

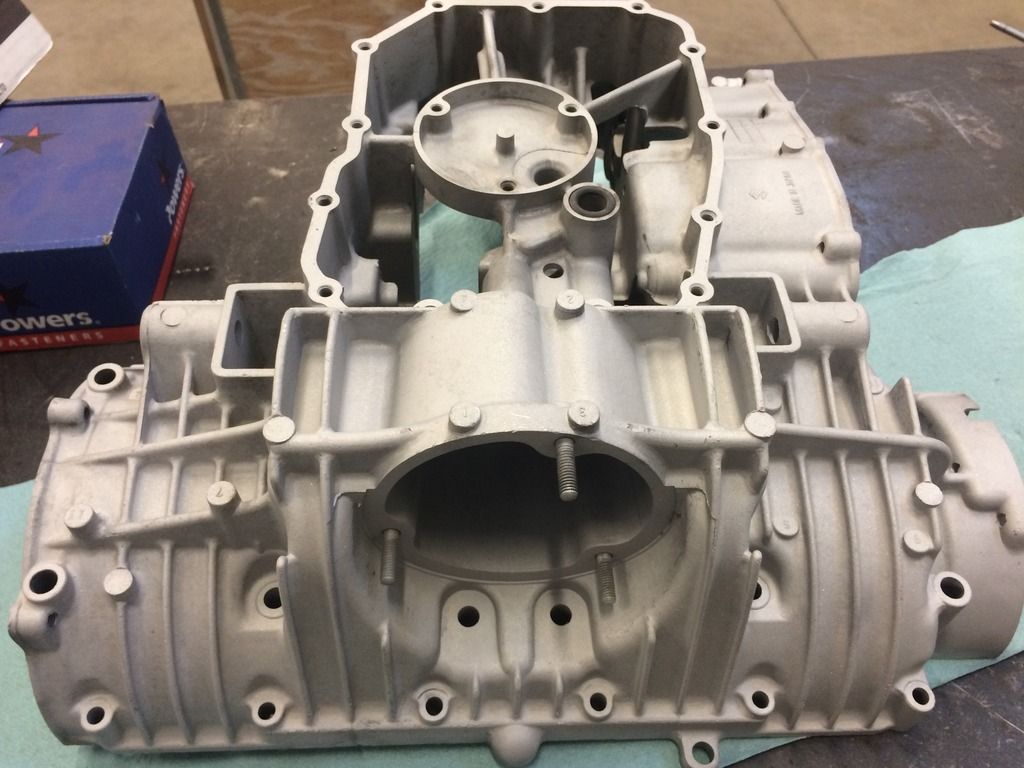

3. Split the transmission cases and ground out the cylinder holes so the 650 cylinders can fit in the cases

4. Put the transmission cases back together and put all new seals in them

5. 3-d printed a few prototype parts

6. Figured out how I am going to do the variable oil cooling system

7. Bought new (to me) gs650 front forks for the brake upgrade

By the end of this build I want the bike to look as stock as possible, and have a little more kick as well. Like I said earlier I am new to rebuilding bikes, so I will be asking a lot of questions. Once I get home tonight, I plan on posting pictures of what I have done so far. I hope you guys enjoy my thread.

Thanks,

Andy

.png)

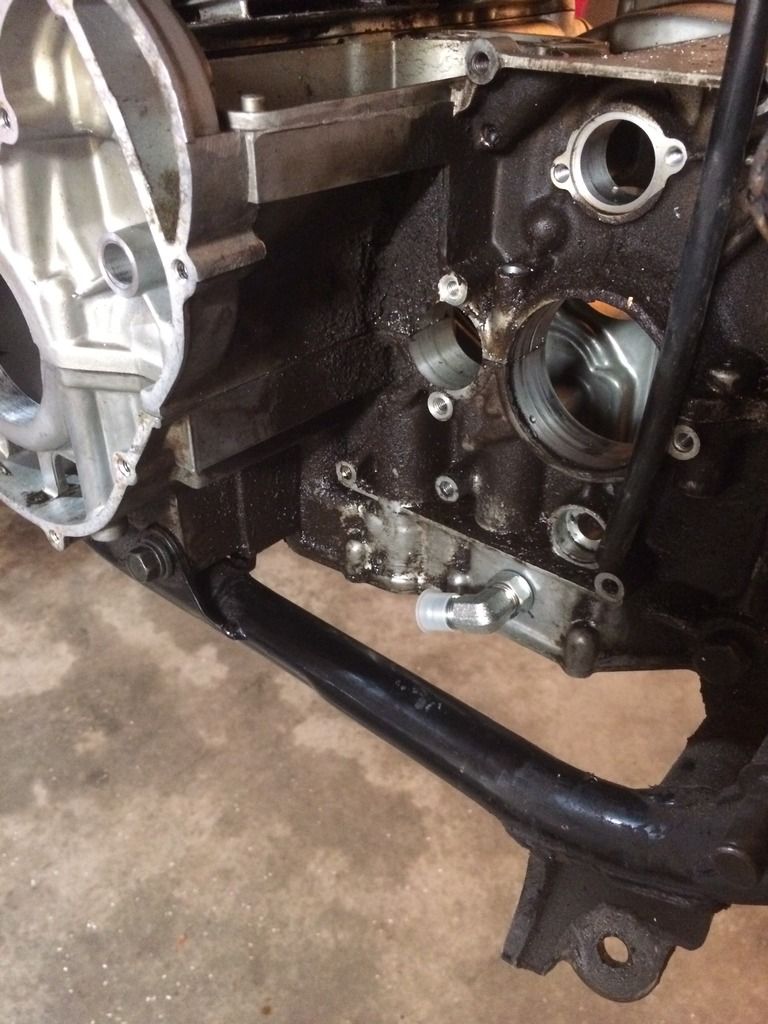

You really only need a smear along the faces - most of what you have there is going to be squeezed out into the engine....which isn't good.

You really only need a smear along the faces - most of what you have there is going to be squeezed out into the engine....which isn't good.

Comment