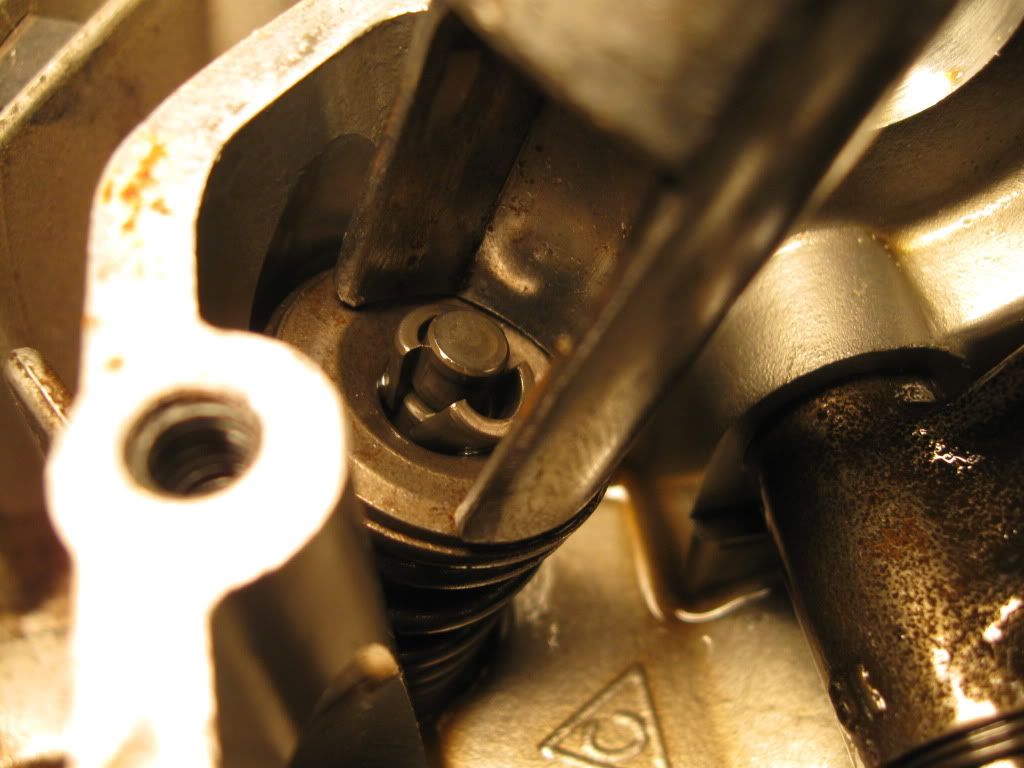

Take one $6.99 harbor freight 8" (200 mm) C-clamp and screw the movable portion down until it tightens against the non-movable side. Scribe a line around the move-able pad and open the clamp fully. Find the center of the circle you made and drill a pilot hole all the way through the non-movable pad. (My drill motor was small enough to drill from the inside) Increase the size of the hole with increasingly larger drill bits until the hole will accept a 5/16"-18 tap (size F-drill bit) and tap the hole. Insert a 5/16" NC allen head cap screw into a 5/8" spark plug socket and tighten securely. Take a cutoff wheel and use it to remove a rectangle from the spark plug socket. Deburr the opening with a file.

** Found the thread. http://www.thegsresources.com/_forum...77&postcount=4

As always the requisite pictures...

OK, I'll take partial credit for that. My original version used a section of PVC pipe coupling, then I used a 24mm deep socket, but somebody else had the idea of bolting the socket to the clamp.

OK, I'll take partial credit for that. My original version used a section of PVC pipe coupling, then I used a 24mm deep socket, but somebody else had the idea of bolting the socket to the clamp..png)

Comment