Announcement

Collapse

No announcement yet.

Camshaft Top End Rattle

Collapse

X

-

You can change the initial advance (& thus the ultimate advance) by slotting the carrier on some GS's.

You can also modify the spring carriers on the advance unit to alter the total advance given. Lastly you can change springs to get the advance earlier or later.

It's all experimental stuff though, not sure how many have done it although I've seen the odd post on here. Shouldn't be too hard to figure out with the parts in your hand.

-

Guest repliedSo you want exhaust to be advanced another couple degrees?

Guest repliedSo you want exhaust to be advanced another couple degrees?

From where you are sitting, you would turn the cam clockwise.

Leave a comment:

-

Guest repliedWhich Wat to Turn Cam Sprocket

Guest repliedWhich Wat to Turn Cam Sprocket

If I were to decide to open up the exhaust timing a bit so it had a 2 degrees lead over the inlet cam which way would I turn the exhaust cam sprocket to make the number larger? Say going from the current 104.5 degrees to 106 or 107. To clarify more I would be working from the right hand side of the bike, need to be on that side to turn the large 19mm nut on ignition advance unit if required, also the two bolts that hold the sprocket are on that side as well and need to be loosened, tightened at the appropriate moments. So looking at the exhaust sprocket from the right hand side of the bike which way would it turn to increase the centeline number?

Leave a comment:

-

Guest repliedDon, this will give me a bit more top end. With the longer duration and the larger overlap, I will lose a bit of midrange, but gain a bit up top.

Guest repliedDon, this will give me a bit more top end. With the longer duration and the larger overlap, I will lose a bit of midrange, but gain a bit up top.

email is mlinder (at) hondatwins (dot) com

Thanks

Leave a comment:

-

Guest repliedLinder this back to front setup you plan to run is the way the 650 timing was originally. When I checked my original 650 cams before I slotted the sprockets the exhaust was 103 and the intake 108 centeline. What effect do you think this has running the cams this way as opposed to the more normal setup of having the exhaust number larger by about 2 or 3 degrees?Originally posted by mlinder View PostDon, I'm actually going with 106 intake and 103 exhaust, with the 550 exhaust cam for a bit more overlap. I'm looking for a little more top end. Required to dethrone my friends crazy cb550 build.

Guest repliedLinder this back to front setup you plan to run is the way the 650 timing was originally. When I checked my original 650 cams before I slotted the sprockets the exhaust was 103 and the intake 108 centeline. What effect do you think this has running the cams this way as opposed to the more normal setup of having the exhaust number larger by about 2 or 3 degrees?Originally posted by mlinder View PostDon, I'm actually going with 106 intake and 103 exhaust, with the 550 exhaust cam for a bit more overlap. I'm looking for a little more top end. Required to dethrone my friends crazy cb550 build.

I documented the original setting up and degreeing of my cams, if you would like a copy then send me your email address, it is a Word document so I cannot put it on this site.

Thanks for ALL feed back.

Leave a comment:

-

Guest repliedBilly I am using the original 550 advance unit which has initial advance at 17 degrees. It has the cam on it to open the points. The 650 advance unit I have has the two lobes to activate the electronic system. Although I may be able to swap parts between both units to alter the advance curve. You say the timing is easily adjusted at a later date if the noise is still there. How is this done?Originally posted by BadBillyB View PostWhich advance unit did you use. One has (going by your figures) 20 degrees of mechanical advance, the other has 30.....Over advancing ignition timing can cause pinging in any engine. I doubt if 7 degrees is enough to cause a problem though, but is easily adjusted later if the noise is still there. I was hoping that your noise would be gone by correcting the deck height. If you run the piston too close to the head, even a small amount of carbon in between could cause a nasty knock....Billy

Guest repliedBilly I am using the original 550 advance unit which has initial advance at 17 degrees. It has the cam on it to open the points. The 650 advance unit I have has the two lobes to activate the electronic system. Although I may be able to swap parts between both units to alter the advance curve. You say the timing is easily adjusted at a later date if the noise is still there. How is this done?Originally posted by BadBillyB View PostWhich advance unit did you use. One has (going by your figures) 20 degrees of mechanical advance, the other has 30.....Over advancing ignition timing can cause pinging in any engine. I doubt if 7 degrees is enough to cause a problem though, but is easily adjusted later if the noise is still there. I was hoping that your noise would be gone by correcting the deck height. If you run the piston too close to the head, even a small amount of carbon in between could cause a nasty knock....Billy

I too hope the noise is gone when I restart the motor.

Leave a comment:

-

Guest repliedDon, I'm actually going with 106 intake and 103 exhaust, with the 550 exhaust cam for a bit more overlap. I'm looking for a little more top end. Required to dethrone my friends crazy cb550 build.

Guest repliedDon, I'm actually going with 106 intake and 103 exhaust, with the 550 exhaust cam for a bit more overlap. I'm looking for a little more top end. Required to dethrone my friends crazy cb550 build.

Leave a comment:

-

Guest repliedHey Don, I looked at your lobe center calculations and it looks good to me. Changing the exhaust lobe centerline will not affect the intake as you are only moving the cam not the chain. I would go with the numbers that Ray gave you (106 on the exhaust) as this will reduce the valve overlap and give you really good bottom end. Which advance unit did you use. One has (going by your figures) 20 degrees of mechanical advance, the other has 30.....Over advancing ignition timing can cause pinging in any engine. I doubt if 7 degrees is enough to cause a problem though, but is easily adjusted later if the noise is still there. I was hoping that your noise would be gone by correcting the deck height. If you run the piston too close to the head, even a small amount of carbon in between could cause a nasty knock....Billy

Guest repliedHey Don, I looked at your lobe center calculations and it looks good to me. Changing the exhaust lobe centerline will not affect the intake as you are only moving the cam not the chain. I would go with the numbers that Ray gave you (106 on the exhaust) as this will reduce the valve overlap and give you really good bottom end. Which advance unit did you use. One has (going by your figures) 20 degrees of mechanical advance, the other has 30.....Over advancing ignition timing can cause pinging in any engine. I doubt if 7 degrees is enough to cause a problem though, but is easily adjusted later if the noise is still there. I was hoping that your noise would be gone by correcting the deck height. If you run the piston too close to the head, even a small amount of carbon in between could cause a nasty knock....Billy

Leave a comment:

-

Guest repliedIgnition timing wouldn't cause a rattle.

Guest repliedIgnition timing wouldn't cause a rattle.

Could easily have been camchain noise from unsynched carbs, could have been valve clatter from 'loose' clearances (someone said once, a noisy engine is a happy engine), who knows.

Leave a comment:

-

I have run GS750 & GS1000 street bikes with both cams set at 105. The throttle response was outstanding and the bikes felt powerful at cruising speeds. Dar

Leave a comment:

-

Guest repliedIgnition Problem Maybe

Guest repliedIgnition Problem Maybe

Seeing as I have not found anything wrong with my motor to cause the noise that was so apparent before i have been looking elsewhere for a solution. There are a couple of things I have been considering.

1. Ignition timing is one thing that comes to mind. The 550 specs indicate ignition timing (with points @ condensers) below 1500 rpm is 17 degrees BTDC. The 650E is only 10 degrees BTDC (transistorised ignition) below 1650 rpm. For comparison the 1000 from '79 is 17 degrees below 1500 rpm. The 550 and 1000 (both with points) top out at 37 degrees at higher revs and the 650E at 40 degrees. Could it be that the 650 with different shape quench combustion chambers requires a more retarded ignition timing at idle and the extra 7 degrees advance I have been running is causing this noise. Or is it just that transistorised ignition can run with less advance.

Any thoughts please?

2. The other thought was that maybe the carbs being out of synch was causing some imbalance and creating this noise because the cylinders were getting differing amounts of fuel at idle?

Any thoughts.

Leave a comment:

-

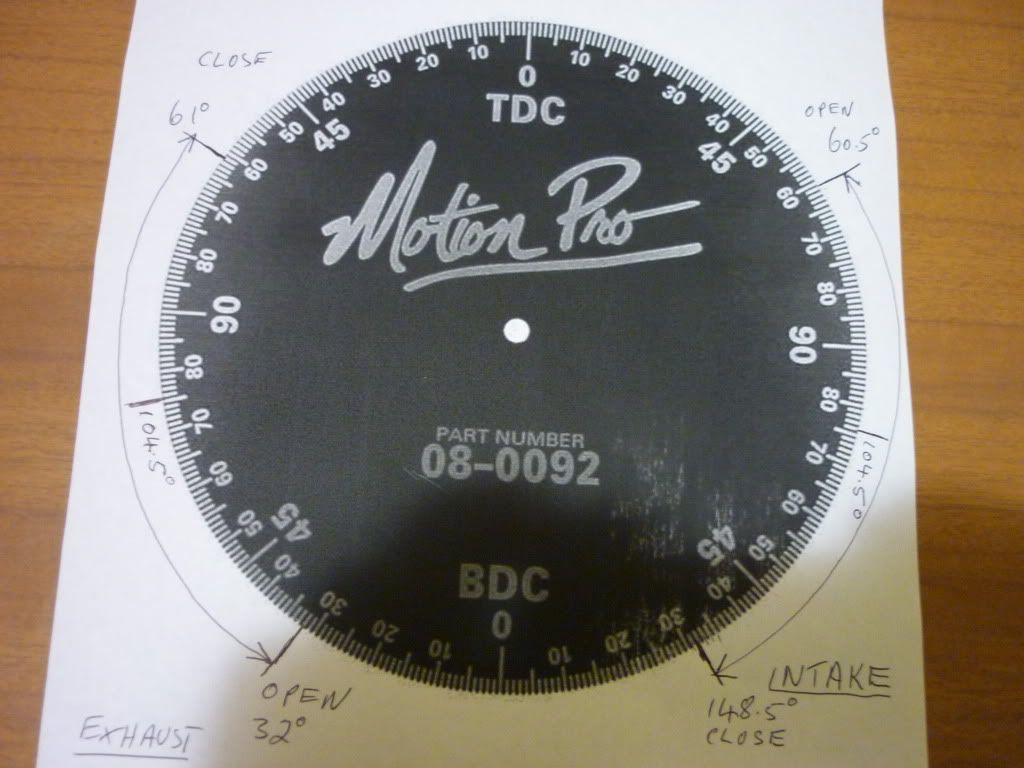

Guest repliedBilly I re-checked the timing using your alternative method (checked it three times) and came up with 104.5 degrees on the intake.Originally posted by BadBillyB View PostForgot to mention there is another way to do this and I prefer it with performance cams.

Guest repliedBilly I re-checked the timing using your alternative method (checked it three times) and came up with 104.5 degrees on the intake.Originally posted by BadBillyB View PostForgot to mention there is another way to do this and I prefer it with performance cams.

Find max lift with the dial indicator

Zero indicator

Turn motor backwards a bit, then forward and stop at .050" before max lift

Mark degree wheel

Roll motor past max lift stopping at .050" after

Mark wheel

1/2 way between the marks is your lobe center

Billy

Then I did a check on the exhaust #1 cam lobe using Billy's altenative degree checking method. This figure came out at 104.5 degrees as well. Degree wheel readings were 32 ABDC and 61 BTDC -- I think my maths is right.

Below is my degree wheel with details of my degreeing process.

One more question, what would performance be like if I ran the cams as they are with 104.5 degrees on both cams.

Also if I alter the lobe centre on the exhaust cam (by moving the slotted sprocket) will that alter the lobe centre on the intake cam?Last edited by Guest; 10-19-2010, 06:16 AM.

Leave a comment:

-

Guest repliedThanks Billy, I will do the intake again when I get home tonight using your other method. Should not take long. The time is spent setting things up, degree wheel, dial gauge, etc.Originally posted by BadBillyB View PostHey Don, thanks for the pic from the right side showing the camshaft cut outs to cylinder head relationship. Just making sure there is no gross error. I forgot to ask you if you used a piston stop tool to find TDC. They are easy to make with an old spark plug. I also see now where the confusion is. The formula used to find the lobe center is based on whether the intake opens before or after TDC. This is directly related to what number lift you measure at. .030", .040", .050" .....In some cases you add the small number and in other cases you subtract the small number....Thats why I prefer the alternate method I described in my earlier post. Theres less room for error. Anyway heres a nice page to use for a guide.....Billy http://www.webcamshafts.com/pages/degreeing.html

Guest repliedThanks Billy, I will do the intake again when I get home tonight using your other method. Should not take long. The time is spent setting things up, degree wheel, dial gauge, etc.Originally posted by BadBillyB View PostHey Don, thanks for the pic from the right side showing the camshaft cut outs to cylinder head relationship. Just making sure there is no gross error. I forgot to ask you if you used a piston stop tool to find TDC. They are easy to make with an old spark plug. I also see now where the confusion is. The formula used to find the lobe center is based on whether the intake opens before or after TDC. This is directly related to what number lift you measure at. .030", .040", .050" .....In some cases you add the small number and in other cases you subtract the small number....Thats why I prefer the alternate method I described in my earlier post. Theres less room for error. Anyway heres a nice page to use for a guide.....Billy http://www.webcamshafts.com/pages/degreeing.html

Yes I did use a piston stop tool and found TDC on the degree wheel and then checked the factory TDC mark over on the ignition end of crank. It was out by a couple of degrees so I elongated the holes and moved the plate to correct it for future use. I also used the piston stop to hold the motor while I loosened the generator rotor bolt so I could mount the degree wheel. Worked OK.Last edited by Guest; 10-25-2010, 04:23 PM.

Leave a comment:

-

Guest repliedHey Don, thanks for the pic from the right side showing the camshaft cut outs to cylinder head relationship. Just making sure there is no gross error. I forgot to ask you if you used a piston stop tool to find TDC. They are easy to make with an old spark plug. I also see now where the confusion is. The formula used to find the lobe center is based on whether the intake opens before or after TDC. This is directly related to what number lift you measure at. .030", .040", .050" .....In some cases you add the small number and in other cases you subtract the small number....Thats why I prefer the alternate method I described in my earlier post. Theres less room for error. Anyway heres a nice page to use for a guide.....Billy http://www.webcamshafts.com/pages/degreeing.html

Guest repliedHey Don, thanks for the pic from the right side showing the camshaft cut outs to cylinder head relationship. Just making sure there is no gross error. I forgot to ask you if you used a piston stop tool to find TDC. They are easy to make with an old spark plug. I also see now where the confusion is. The formula used to find the lobe center is based on whether the intake opens before or after TDC. This is directly related to what number lift you measure at. .030", .040", .050" .....In some cases you add the small number and in other cases you subtract the small number....Thats why I prefer the alternate method I described in my earlier post. Theres less room for error. Anyway heres a nice page to use for a guide.....Billy http://www.webcamshafts.com/pages/degreeing.html

Leave a comment:

-

Guest repliedWell Billy if your maths is correct and I believe it is as I'm only a learner on this cam degreeing thing then 105° is the same as my original cam timing for the intake. So I should not have to alter anything. I have done cam timing previously only by following a formula, i.e. 5 + 180 + 35 / 2 = 110 - 5 = 105° and so on. I now understand what is actually happening in practical terms. Thanks Billy.

Guest repliedWell Billy if your maths is correct and I believe it is as I'm only a learner on this cam degreeing thing then 105° is the same as my original cam timing for the intake. So I should not have to alter anything. I have done cam timing previously only by following a formula, i.e. 5 + 180 + 35 / 2 = 110 - 5 = 105° and so on. I now understand what is actually happening in practical terms. Thanks Billy.

I will check the exhaust when I get home tonight.

BTW here are the numbers from the initial cam degreeing exercise when I slotted the sprockets.

FINAL CAM SPECIFICATIONS: (Using Dial Gauge Method – measured @ 0.030”)

EXHAUST CAM:

Opens: 35.25° BBDC

Closes: 2° ATDC

35.25° + 2° + 180° = 217.25° DURATION

217.25° / 2 = 108.625° - 2° = 106.625° LOBE CENTER

INTAKE CAM:

Opens: 5° BTDC

Closes: 35° ABDC

5° + 35° + 180° = 220° DURATION

220° / 2 = 110° - 5° = 105° LOBE CENTER

Last edited by Guest; 10-18-2010, 03:44 PM.

Leave a comment:

.png)

Leave a comment: