GS1000G mods- big bore and fuel injection

Collapse

X

-

GS1000G Shopper

GS1000G Shopper

Yep, it's definitely the F-word. I've flagged the project as non-viable on the first post for now. -

coombehouse

coombehouse

A bit hasty with the non viable bit as it works for me & many others. Just a thought have you tried your single pickup with the largest wheel with ms extra firmware rather than the b & g firmware. That's what I used successfully after a bit of messing with the air gap. Please don't give up.Comment

-

GS1000G Shopper

GS1000G Shopper

I wouldn't call 6 months of work exactly hasty. Take a look at some of the other FI threads here & see how far they got & how well documented the project was. They just gave up & never had the courtesy to warn others of the non-viability.

I need some more time to cool down & save up some $ for the next attempt.

I'm going to sandwich all 3 of the 12-1 wheels I had made onto the shaft, they are .125" thick and the sensor is wider than that. It's a free mod, so I'll see if it makes a difference, need to reload the MS Extra FW so I can post the trigger output on the other forum.

I have the air gap down to about .035" the last time I checked.

I've been using MS Extra ever since I realized the B&G forum was a ghost town.Comment

-

Pulse to pulse timing accuracy issues are a classic problem but mainly if you do it wrong.

As Coomebehouse is ."hammering home" get better software/firmware.

You should be able to calculate the variation tooth to tooth in your mag pickup and come pare that to your measured variations; see if it makes sense.Last edited by posplayr; 06-21-2013, 09:16 PM.Comment

-

GS1000G Shopper

GS1000G Shopper

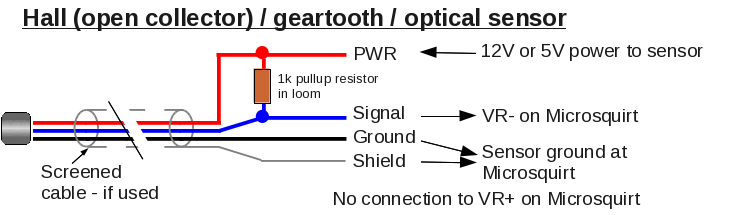

Did some reading here, and there may be a semi-magic bullet. Pamco makes a Hall effect ignition for the CB750 that can be adapted to the GS (see post #13). Apparently they made one for the GS but sales didn't support it. It looks like they focus on the Yamaha XS market.

The gurus at MS Extra say this will work by locking out the mechanical advance (already done), using a spark driver (already done), and adding 1K pull-up resistors (cheap since I have a bin full of them). At $120 + shipping it's almost as cheap as trigger wheel machining cost.

Last edited by Guest; 06-21-2013, 11:19 PM.

Last edited by Guest; 06-21-2013, 11:19 PM.Comment

-

GS1000G Shopper

GS1000G Shopper

Consistent lack of being able to accept an input. It should have worked from the coil, to include the GSXR wiring variations I tried that were supposed to "fix" the problems.

It may just be the input, as the readout I'm seeing on the tachref program is supposed to be from the trigger itself, but it seemed odd that it didn't work via several input variations. Now that I think about it more, when I loaded the OEM FW, my coolant sensor reads way low- like 20 below 0. It works properly with the MS2 Extra FW. All other sensors read correctly.

I'm going to try the Pamco and if that doesn't do the trick, I'll keep it and reinstall the carbs.

Still have a head gasket job to occupy some time.

Comment

-

Guest

Guest

Up?

Hiya GS-G

I have an opinion here so please don't be offended. Why spend the time with making a small trigger wheel? I think they are just too small. With a larger wheel, you get a stronger signal as the teeth move past the pickup faster. And maybe try to reverse the wires on the pickup?

Just get a newer trigger wheel off of Ebay for a 2003+ GSXR1K or 2004+ GSXR750/600. And maybe get yourself a GSXR pickup as well. Move the pickup further out on the plate to clear the new wheel and then start. Dump the voltage reducer for the fuel pump as well as right now, nothing is seeming to work. And after all this, I had GPZ1100 F.I. on my Katana running very well many years ago so I don't see why such the trouble.

As for prices, how much for all the trigger wheels? And the special parts when you could have picked up MY GPZ 11 stuff for $150 and not have had to mess with anything? Yes, it's not programmable but it was workable. And my latest adventure is using the newer GSXR F.I. on a GSXR1127. ECU Hacking forum has a few guys doing this with great results.

Please, don't take offense because of my opinion but I think you have severely over complicated this.

Thanks for listening.

GregComment

-

GS1000G Shopper

GS1000G Shopper

I'm not offended, but if you read page 1, one concept here was for this project to be repeatable so others could do it. Let's say I get a super deal on some GPz parts. What then does the guy 6 months or a year from now do when they want to convert their GS?

One thing that really bugs me on forums is when member "A" says I have problem "X". You have the same problem some time later and find their thread. As you read it, member "A" then follows up and says they figured out how to fix it- but doesn't say how. After this happened to me several times, I thought I'd always try to write threads so others could benefit from them, be it replacing the lights on a Vetter trunk or converting to fuel injection. In my day "job" I deal with a lot of complaining. I complain also, but try to offer a solution when possible.

I wouldn't know if the small trigger wheels would work until I tried them. Engineering parts is at times a trial and error method, I researched info and measured/remeasured and they fit as designed the first time (a rarity for me). I reckon Mr. Suzuki went through this process a time or ten before the first GS was built. If they had worked as designed, then there would have been a very cheap means of ignition triggering. Also, regardless of the wheel size, the teeth move at the same speed since they are at a 1:1 ratio with the shaft upon which they are mounted. I agree resolution was an issue with the first set of wheels, but see no reason why the 12-1 wheel would not work, there was plenty of space between the teeth and they were nearly as tall as the OEM single tooth. If nothing else, I learned how to design a new part I had never designed before. I can now make trigger wheels of any tooth count/thickness or size as needed. I even designed a one piece replacement w/ wheel for the entire advance unit that would bolt on. Price for 1 was sky high though.

The fuel pump will sort itself out. I really think it just needs a reset, but it's currently disconnected until I get the trigger worked out.

As it stands, the Pamco setup looks workable and nearly bolt-on (always a concern). The same cannot be said for the GSXR trigger setup, the wheel must be adapted to the shaft, and then the pickup mounted. The GSXR wheels I looked at on eBay had 8 teeth with no missing tooth. I'm not sure this would be compatible with Microsquirt input options. Even if the Pamco does not work for the Microsquirt, it's an improvement over the stock setup and can be used with carbs if need be.

This process is a PITA, but once it is completed, that makes it 1,000 times easier for the next person. This week is one of the low points in the project.Last edited by Guest; 06-22-2013, 11:38 AM.Comment

-

coombehouse

coombehouse

My input yet again.

The Gsxr pickup is identical to the gs . The GS just has 2 that's all. I know because I have 1 which I managed to break! Agreed that I do think you have made this install a little more complicated than necessary but hey like you say, you now know what not to do from personal experience. That said I did take the easy route & go with accepted practice of a 36-1 wheel & single OEM pickup which works great & fits easily with a little fabrication. I think too that we all know that this type of mod never will be an easy bolt on. You need to have fabrication skills & equipment.

Incidentally the air gap between tooth & pickup that works for me is 0.004". I would think yours is much too large at 0.035".

NickComment

-

GS1000G Shopper

GS1000G Shopper

That's the most valuable info I've learned all day. When I tried to find what the gap should be, the numbers I found ranged from .030 to .080. No one seems to publish this info for bikes.

MSD for example says to use .050 (and no less) to .080.

Crane Cams says to use .045 to .060.

Aerospace components say to use .060 to .080.

Porsche crank trigger .030 to .035 (what I used).

I'll try & tighten it up to see if this makes a difference, thanks for the info.Comment

-

coombehouse

coombehouse -

coombehouse

coombehouse

Comment

-

GS1000G Shopper

GS1000G Shopper

I got the gap down to .010, as tight as it would go. I was still getting an inconsistent pattern.

I noticed after reloading the MS2 Extra FW, I was not getting an RPM reading on the dash. I reversed the wires from the pickup and got an intermittent RPM reading. I then saved a "trigger log" which is a csv file, so the gurus at the other forum can analyze it.

EDIT- screencap with trigger pattern

Last edited by Guest; 06-22-2013, 04:25 PM.

Last edited by Guest; 06-22-2013, 04:25 PM.Comment

Comment