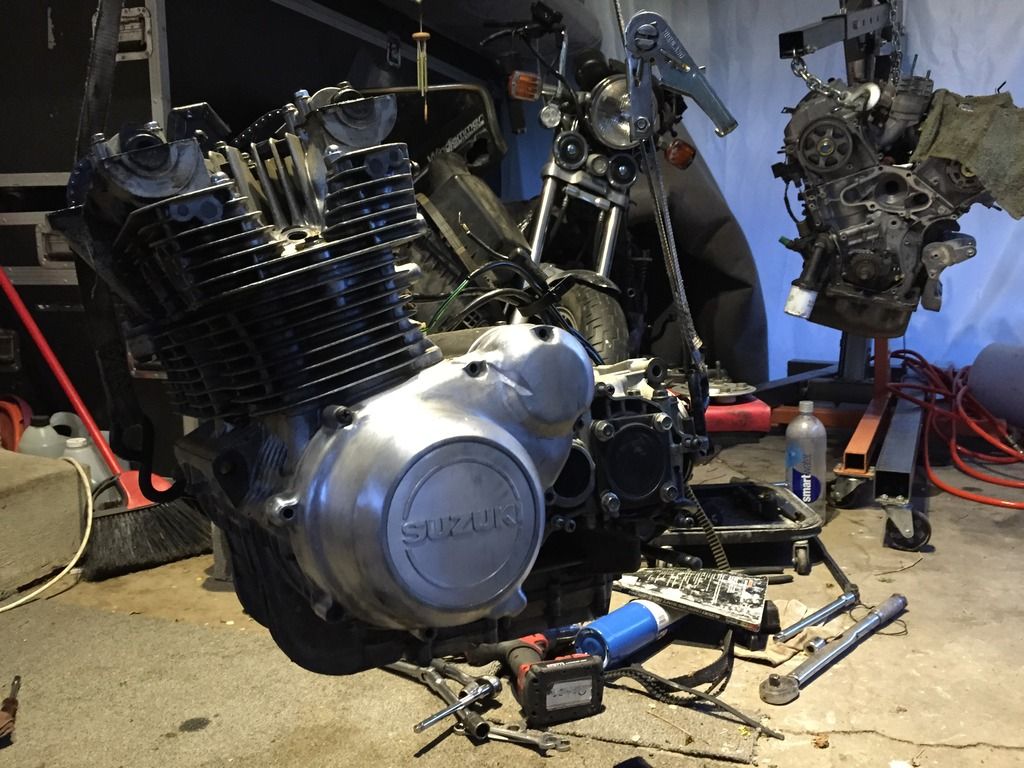

78 750 bottom end, 78 750 cams, 83 850 cylinders ( stock bore, de-glazed on sunnen machine), 83 850 head surface milled 0.020"

Engine is completely dis-assembled, going to be checking piston to valve clearance with degree wheel and dial indicator. (no play-dough, lol)

Questions are...

Does anyone's know the stock, or acceptable piston to valve clearance on an 83 850? (no info in FSM)

Does anyone know the compressed thickness of the OEM GS 850 headgasket? (do not have the old one to re-assemble, only the stock 750 one)

Are their any other metal head gasket's available for the 850 with different thickness's? (i.e. cometic, wiseco, etc.)

At what degrees's should I check (and be worried about) for intake valve ATDC and exhaust valve BTDC contact?

Cheer's everyone,

Darren

Comment