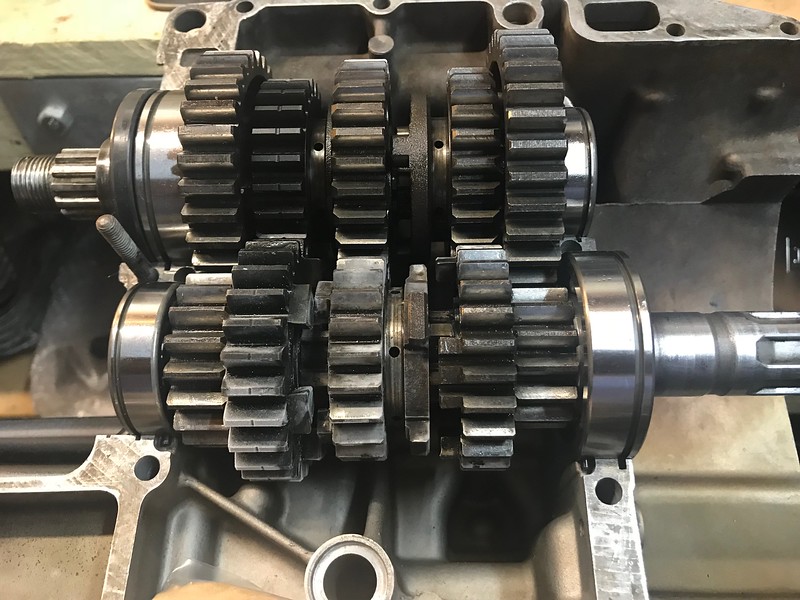

Second gear is a press fit on the countershaft, held in place by friction and high strength thread locker.

They say you can replace the gear twice before having to replace the shaft, and due to first being integral with the shaft, to replace any other gears you need to press second off and back on again, and of course I have no idea how many times that may have been done already. In this case fifth needed replacing, so second had to come off.

When we got second off, we noticed marks/burring on the shaft and inside of second that indicate it may have spun a little already.

So, given all the above, welding was the recommended course of action and is a very common fix to sort the issues.

In my mind it's also part of trying to make sure the bottom end is as solid as can be to avoid needing to pull it apart again any time soon.

Comment