Suzuki GS1000e/s/gs1100/gsx1100 project...

Collapse

X

-

I noticed you fitted the "Salty-Monk" front brake upgrade.

What are the exact disks and calipers you used?

I understood SV 650 and CBR 600 but there are so many variants that I'd like to make sure I buy the right ones.

Congrats on the build!Leave a comment:

-

Yep, you're not the first to see this problem. Maybe the 3rd most common GS problem behind the charging system and clutch... Loc-tite and a little extra torque and hope for the best.Leave a comment:

-

One of the benefits of owning and maintaining our old bikes is you tend to know all the little noises the engine makes. On idle there has been a ticking noise that had started to get louder, not to the point it was a loud metallic noise but enough to hear it with my helmet on, raise the revs off idle and the noise went.

We all know that ticking noises are notoriously difficult to pin the location down and I thought it was a shim. The cam cover was removed, clearances checked and found to be spot on.. I started to think I had an internal problem until I went to fire the old girl up and it just spun up and rattled. I removed the stator cover and found...

I managed to get the broken ends of the bolts out and you can see the cause of the ticking noise was the loose cap heads rattling around in the starter ring., luckily there was no damage and the small amount of filings were on the magnets for the stator.

A top tip for removal of the rotor assembly, you can use the swing arm pivot bolt instead of trying to find a puller that will never fit properly. As you tighten the bolt tap the free end with a hammer and it will pop off without damage and no use of Anglo Saxon words, and yes they are safety crocs.

Last edited by bobtail84; 12-17-2022, 06:48 AM.

Last edited by bobtail84; 12-17-2022, 06:48 AM.Leave a comment:

-

Update time.

One of the biggest challenges with our bikes after the motor has been modified is making sure the air fuel ratio (AFR) is correct. One option and possibly the most popular is dyno time which no matter which country you are in is expensive so I am looking at an alternative for my bike.

I have bought an Innovate MTX-L Plus wide band AFR gauge with a Bosch LSU 4.9 wideband lambda sensor. I have also had a grown up weld a TI lambda boss into the TI exhaust.

_20220313_161745.jpg?width=960&height=720&fit=bounds)

I have tuned fuel injection engines using WB lambda sensors and tuning carbs will be fun. I can data log the sensor and the main difference is I will be riding the bike instead of sitting on a dyno, I will see how that goes.Leave a comment:

-

Wheelie school? Excellent!

Nice to use someone else's equipment to learn.Leave a comment:

-

Thanks Glen, I would rather say it how it is than miss lead folks into a conversion that was not a real benefit to the bike or person riding it.

My bike is ready to ride all year which mean road tax, MOT and insurance must be done but that means if I wish to throw my leg over the bike I can. ��

One other thing I will be 57 this week and I have booked myself a day at a wheelie school on 10 October 21. I will take the car as the temptation will be too great on the way home if you get my meaning.. I have never been any good at wheelies so I figured it would be fun to try in a controlled environment with an instructor and bikes that have a system to stop you going over the back, I will keep everyone informed about the day.Last edited by bobtail84; 09-05-2021, 08:19 AM.Leave a comment:

-

Nice. Thanks for the honest assessment of ?because you can?.

I?ve been quietly watching this thread. I dig your bike and the fact that you?ve done track days with it.Leave a comment:

-

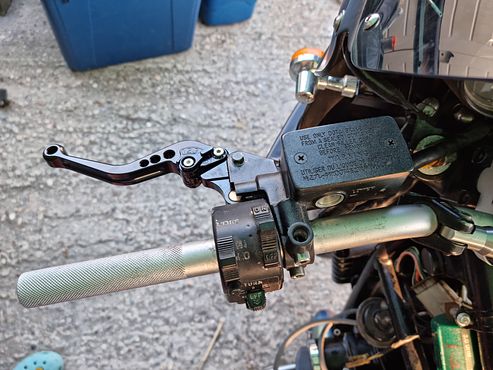

Hydraulic Clutch Conversion

There have been a few threads around the pros and cons to the hydraulic clutch conversion for the GS1000 and I have been mulling the idea over for a number of years and for no other reason than the fact I can I have done the conversion.

Parts needed.

I have used a GSF1200 Bandit master cylinder sourced 2nd hand from eBay ?20, 1m or 3'3" of Goodridge braided stainless PTFE hose with 1 M10 90deg 3/8 banjo ad 1 straight extended neck M10 3/8 banjo ?35.95, 1 Chinese slave cylinder with rod ?17.99 and 1 clevis fork end 5mm ?2.99. The whole lot was ?76.93 or $105.

I realise that a new cable is considerably less but I was collecting the parts over time and I was not worried about the cost.

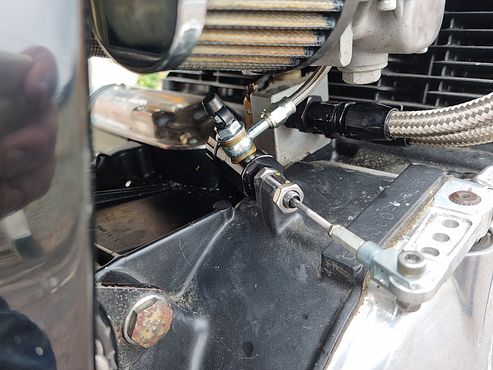

Next I offered up the slave cylinder to make sure it was lining up ok and did not foul the carbs.

Then I added the hose with the banjo fitted to get the best angle for the blead nipple and plan the route for the pipe between carbs 3 & 4.

Next the master cylinder was fitted

Then the hose was run up to the master cylinder

The hose was offered up to the 90 deg banjo on the master cylinder and marked for cutting to length, I could have left the extra on the hose but it would not be right.

Then the hose was fitted and tightened up

This is a short vid of the conversion in action after bleeding which only took 10 minutes.

https://youtu.be/USBIIe2pVsc

I was really pleased with the final fitment and the force to operate the clutch is slightly lighter compared with the OE cable, probably not a conversion to replace the cable for a big reduction in leaver force but for a because you can conversion it is worth it in my opinion.

Last edited by bobtail84; 10-28-2021, 01:38 PM.

Last edited by bobtail84; 10-28-2021, 01:38 PM.Leave a comment:

-

Thanks Rick, to be fair the tail and fairing are a different black and the fairing is satin.. I will get around to painting the bike and it's on the list...

Leave a comment:

-

Guest repliedVery nice Bike Jeff,

Guest repliedVery nice Bike Jeff,

If it was mine I would paint the fairing and tail the same colour as the tank, it's a lovely build whatever you decide,

Cheers,

RickLeave a comment:

-

Hi Tom, a picture would be fantasticThe brake torque arm on my GS1100 is modified, sometime in the distant past someone cut a couple inch section out just where the tire would rub and welded it back together with a patch, very clean. But I have no idea if such a mod would give you enough clearance. If you want a picture let me know.

Leave a comment:

-

The brake torque arm on my GS1100 is modified, sometime in the distant past someone cut a couple inch section out just where the tire would rub and welded it back together with a patch, very clean. But I have no idea if such a mod would give you enough clearance. If you want a picture let me know.Leave a comment:

-

Leave a comment: