The past few months I've been collecting parts for my build. I wasn't planning to do anything at all but I was able to trade some parts for head work and that got the ball rolling. Since I needed to remove the head I then compromised the base gasket and because I had to take the engine down for new gaskets I knew it'd be a good time to do additional work to the bike.

Up to about 6 months ago my bike has had some basic mods including a 4-1 V&H pipe, VM33 smoothbores, accel coils, dyna 2000 ignition, marzocchi shocks, fork brace, braided steel lines, and 1150 cams. This fall I was able to score a cheap wet nitrous setup for a 4 cylinder engine. I bought a 2.5lb bottle and kinda got wrapped up in it. Now I own a nitrous transfer pump and two 50lb nitrous cylinders which I also scored on and actually made money on after I sold off the 5 other tanks that were included. I kept an extra tank and the pump and also some accessories.

Anyway, I've been running a 48hp shot this fall and had some clutch slipping problems so I put in some stiffer springs. I was ready to put the bike away when I was able to make the trade with Terry for the head work. So I pulled my head - got the itch - and started gathering parts.

What my plan to do was to build a bang for your buck bike. Mostly using good used parts without being too invasive. Ideally I wanted to go with a 1229 kit because the cases would not have to be modified to fit that combo. I later found that it was very hard to source a used kit with 18mm pins for the 1100 crank. After some searching I wound up sourcing a 10.25:1 Wiseco -- 1166 kit from a member on this site. I would've like to go a little bigger but the price was right and i was only giving up a few cc's.

For cams I decided to go with G4's. They seem to be the best cam that fit without messing with guides, however it is recommended to grind the oil bumps down on the rocker arms. The lift on G4's is 0.355". I picked up a few sets but they seem to be in pretty sad shape... as seen here and here

I have talked to several members on the site and some have used these cams without HD valve springs. Rather than getting HD valve springs or using stock springs I have decided to shim my valve springs 0.060" to increase the pressure a little. Cost - $7.

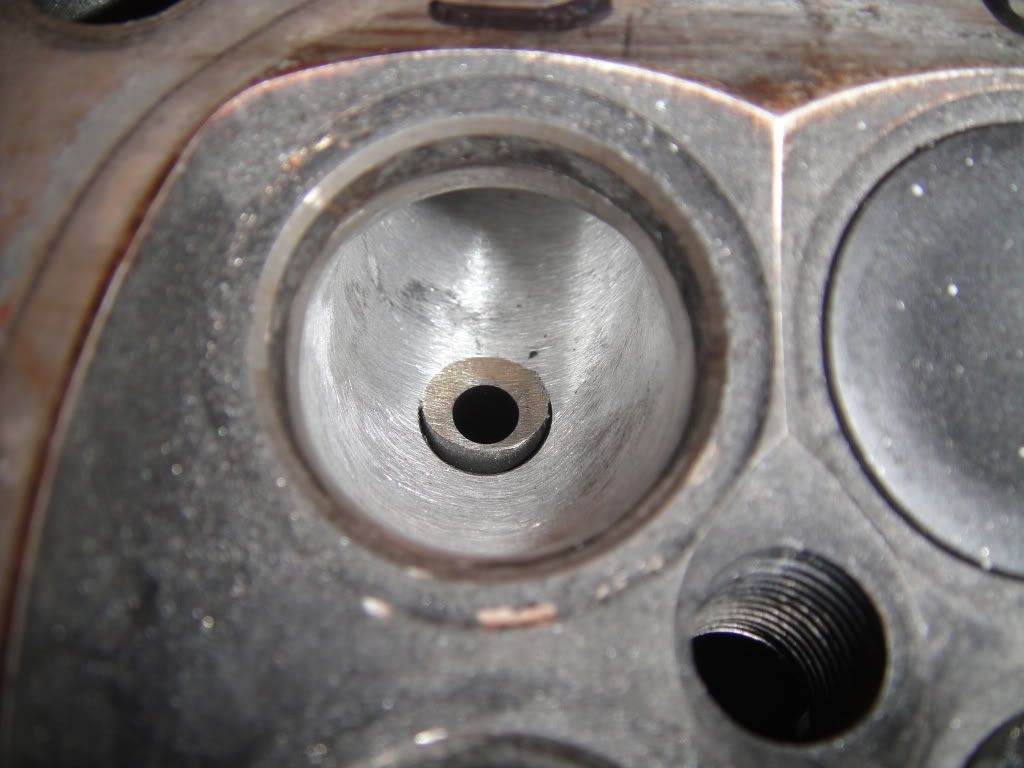

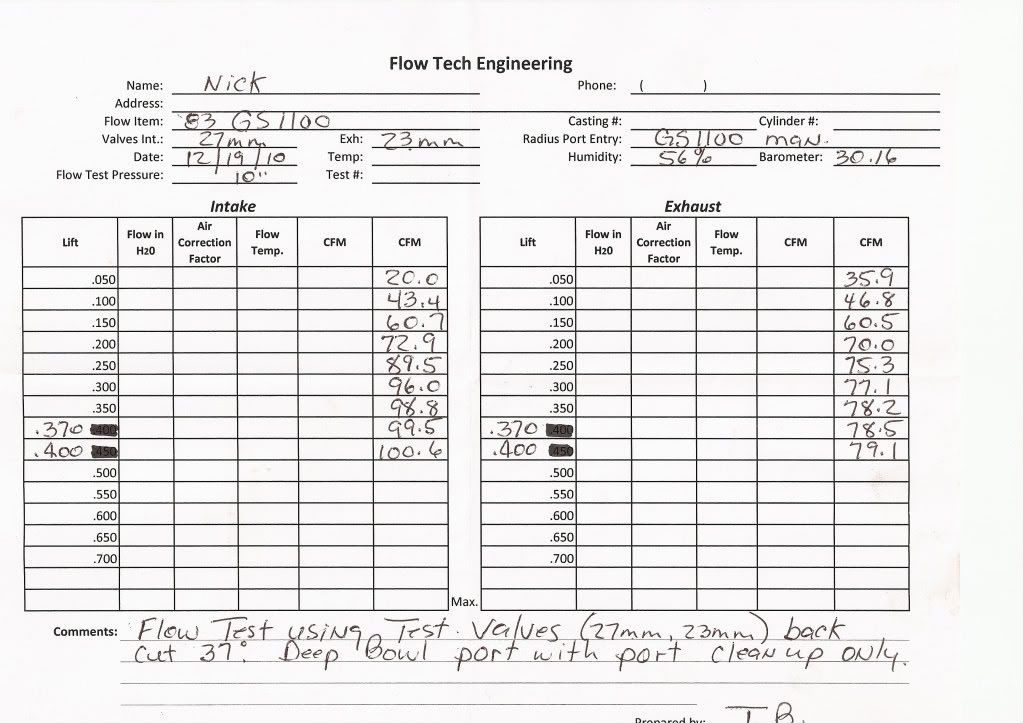

As far as headwork goes Terry built me a very fine head which I am excited to use. He has also been very helpful answering my many questions in great detail. The intake flows ~100CFM and the exhaust flows ~80CFM at 0.4" of lift and at 10" vacuum.

You can see very nice graphs, pictures and comparisons between different heads Terry has done along with the flow of a stock head:

While I have the head down I am also going to replace the valve guide seals.

Up to this point I have the 1166 bock and pistons, some G4 cams along with my ported head. I am ordering the gaskets, valve guide seals, and various other parts this week.

My crank is welded and my clutch basket is built a little; it's been welded but no HD springs or backing plate. I have the helical crank gear which is going to be my limiting factor. According to Ray I should be putting out around 140hp at the rear wheel. I am planning to reduce the nitrous from a 48 shot to a 36hp shot. I rigged up a relay system to retard the ignition timing when the nitrous is activated. because my bike doesn't have blinkers i wired the arming switch into the left turn signal. That way i have the controls at my finger tips and I have a light on my dash to tell me that the system has been/ is armed. When armed my horn button then switches to become the firing mechanism for the nitrous (with the WOT switch inline of course).

I'd like to thank Terry, Posplayr, Rapidray, Racing Jake, Rosco15 among others for their help with answering questions and helping me.

Here are some pictures of everything so far:

.png)

Comment