I'm probably in over my head but I've got the time and want to learn.

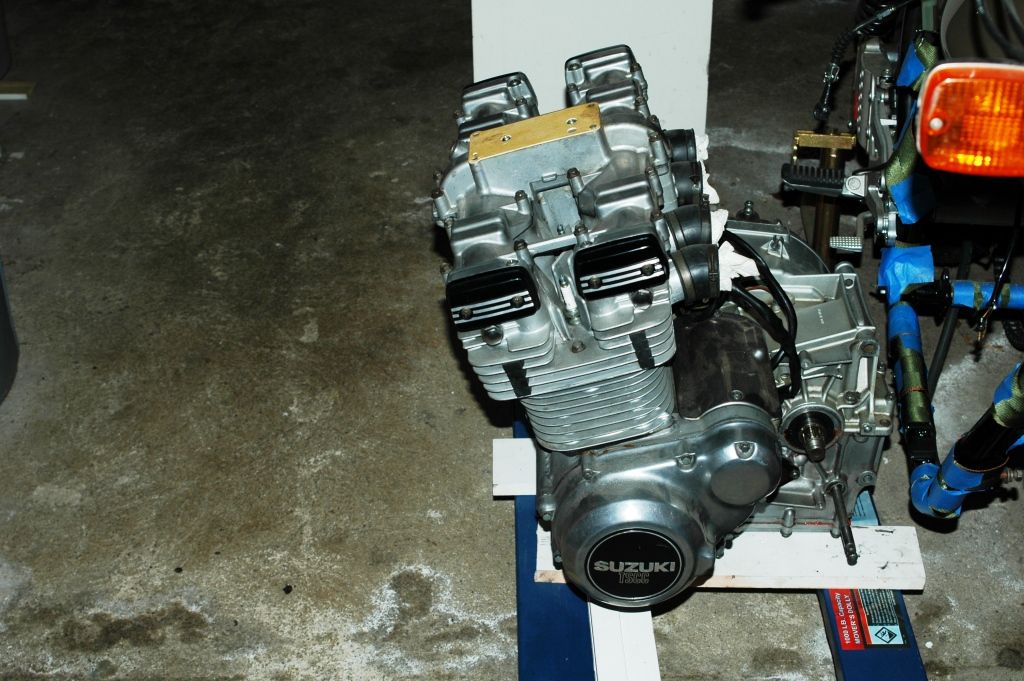

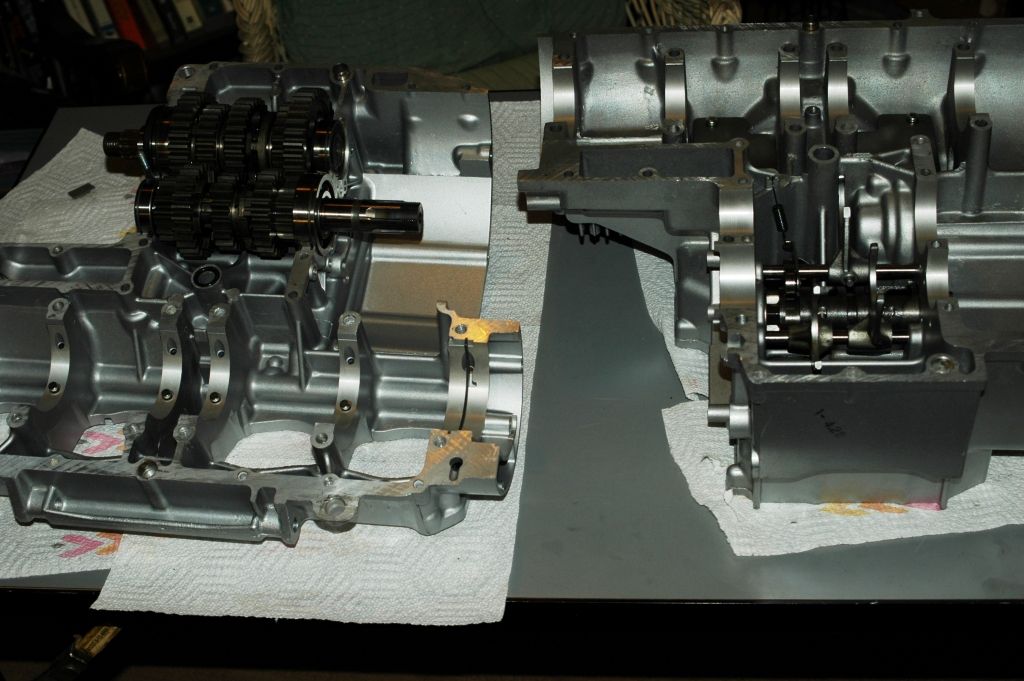

I'll start a project thread soon when I have more photos. I've started assembling the new lower cases but haven't torn into the old engine yet.

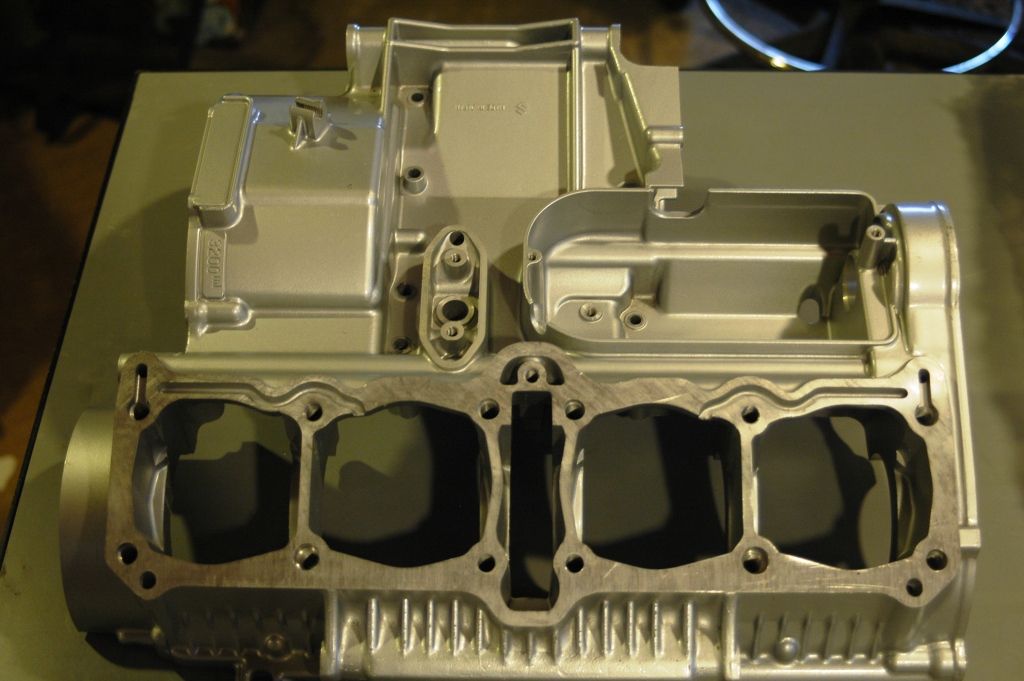

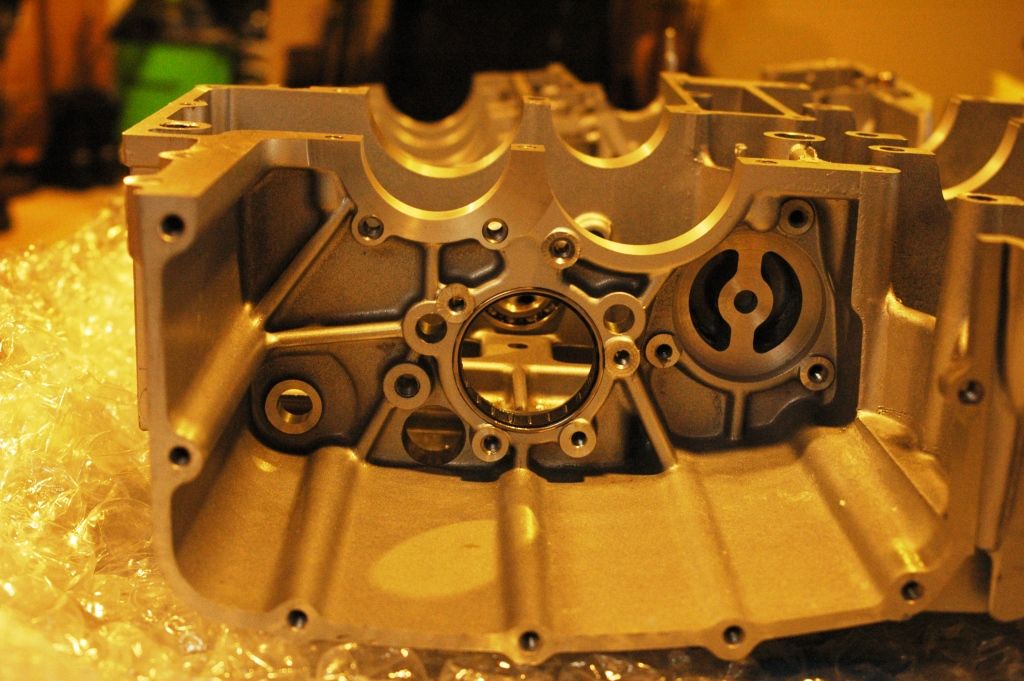

I have a set of NOS silver cases with no serial numbers. It came with a oil spray nozzle already installed in the upper case.

Why is there only one nozzle? Seems like there should be one for each bearing. I plan to install high volume 750 oil pump gears, do you still use the nozzle with the higher flow? Thought I read something about possibly not using it.

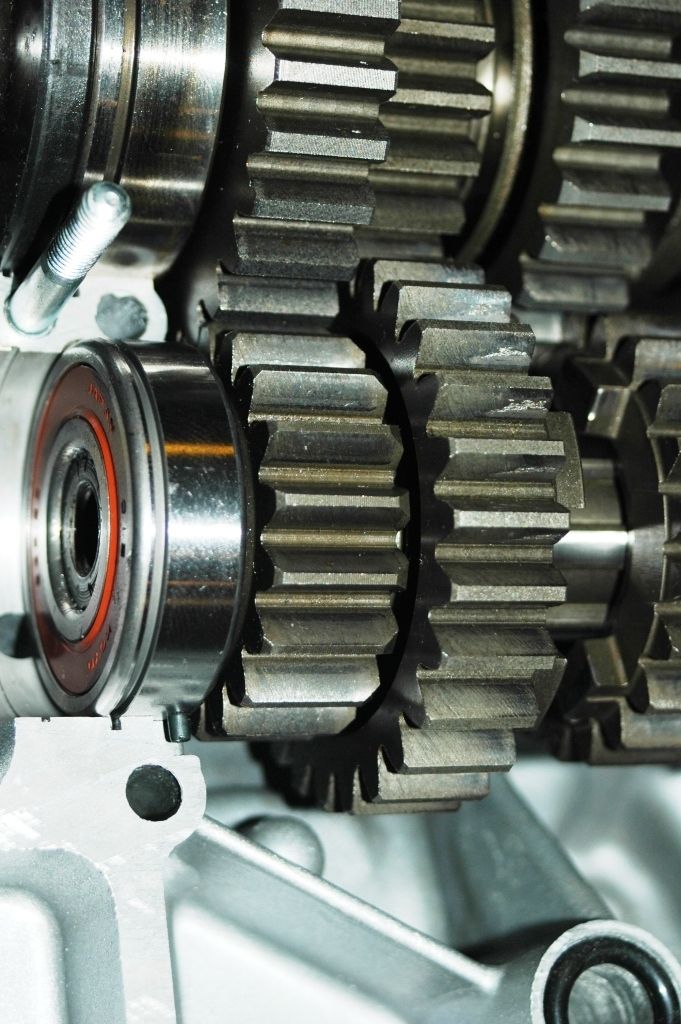

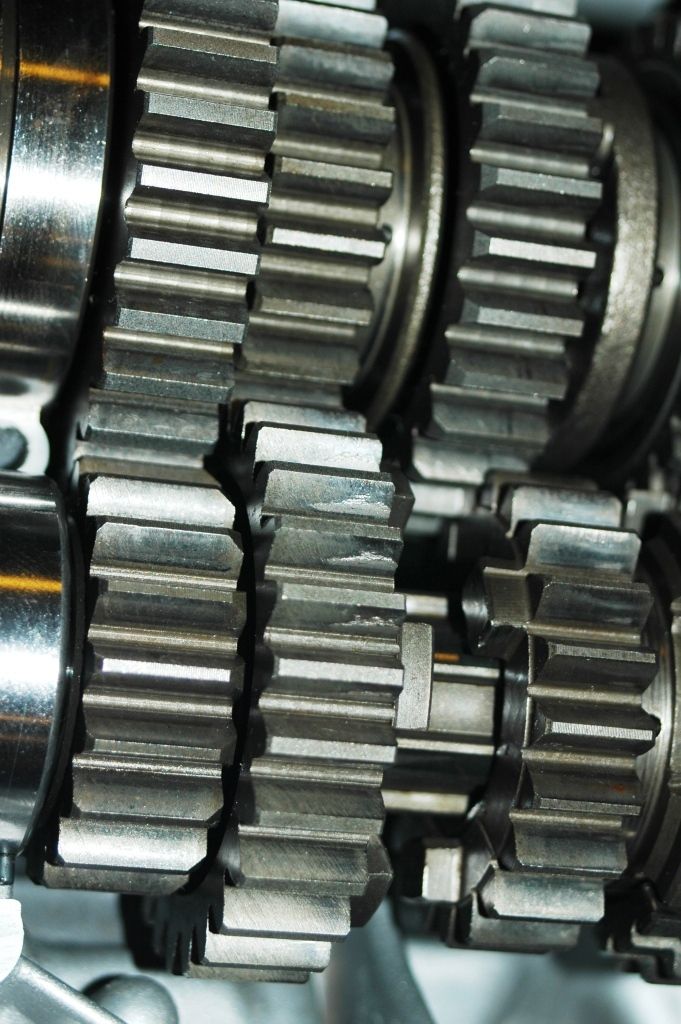

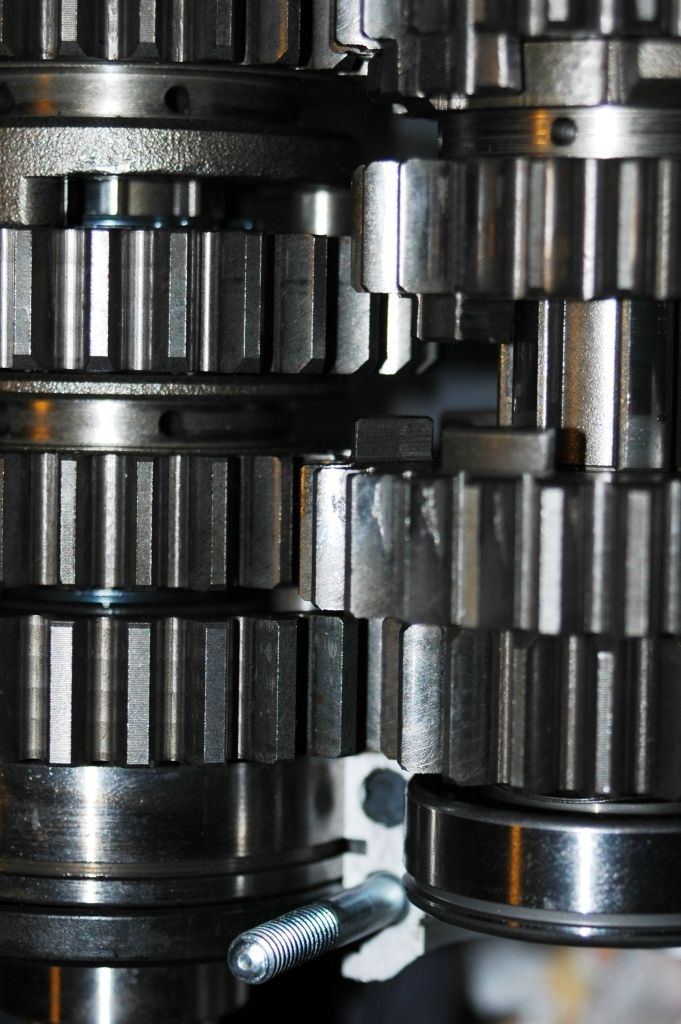

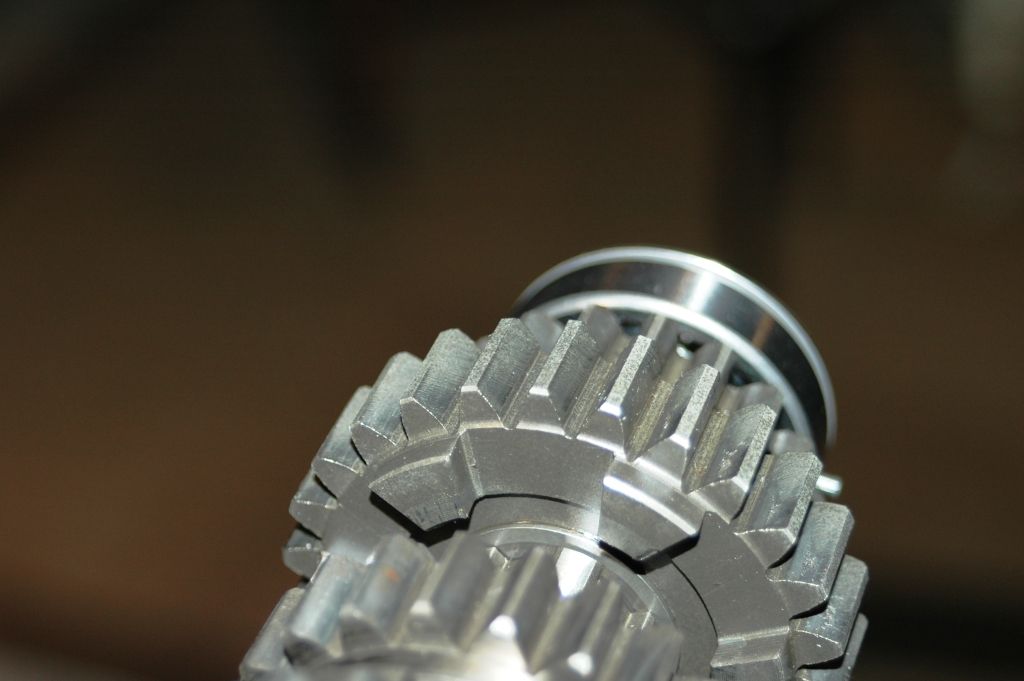

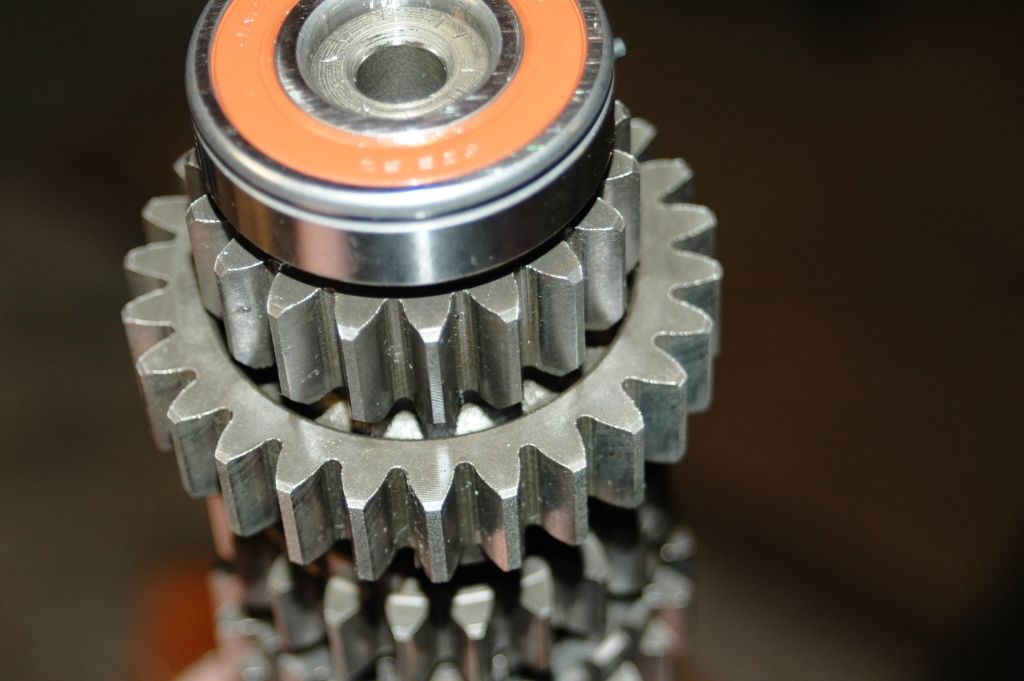

On the spare transmission I plan to use, three of the four outer bearings have a locating pin sticking out that gets held in place by the assembled case halves. The manual says they should all have the locating pins. The bearing that doesn't is the small bearing on the clutch side of the output shaft. I assume they prevent the bearings from spinning. Are they critical? The transmission in the bad case engine probably has the bearing I need.

Lastly what labor saving steps can you suggest? Should I leave the pistons on the crank?

Comment