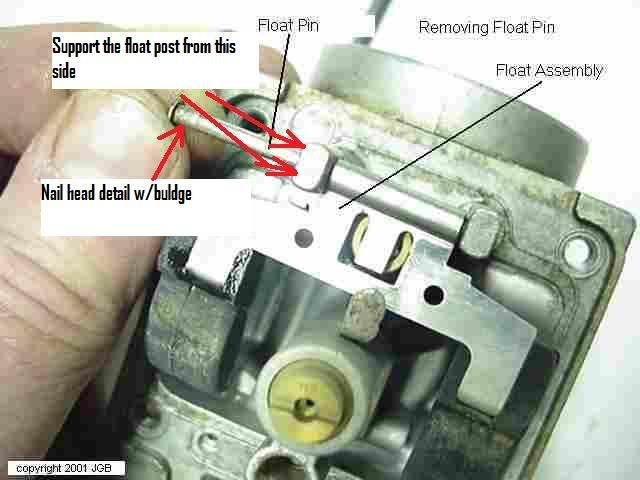

Everything was fine till I tried to take the float pin out even supporting it and the feebelist tap and the post broke, doh!

I didn't get many pictures that I wanted but I got these with my phone.

I JB welded it and drilled straight down, unfortunately the JB didn't hold but it was enough to get the drill down.

A piece of stainless tig wire a bit slack in the hole so I kinked it a bit here and there, mixed up some fresh steel weld.

glued and tapped it down

Smeared and tapped the broken piece home.

I hope that's done the job, I was told it would be fiddly and tricky and it was, all the pins were tight so I put a small flame from the blow torch and they came easily as they seem to be tight on the post that has the head on the float pin.

.png)

Comment