Announcement

Collapse

No announcement yet.

1984 Katana 7/11

Collapse

X

-

Hi Pete,

Been quite a while since I've been able to check in - took me several hours of reading to "Katch" up!

You're doing awesome! Your Kat looks amazing!!! What amazing work you are doing - very inspiring.

And, of course, your fellow GS'Rs (and Kat mates) helping with their expert advice.

Keep it up and THANK YOU for sharing!!

-

Cheers Greg and that's good to know, some of the other guys locally have had good success with it also so fingers crossed mine holds up as well. I also had a few chips when doing the bottom end bolts but I at least expected that due to the paint being soft at that point.

I did see a tip on another forum to give the parts a once over with a heatgun which won't do the same cure as proper oven heating, but should at least help with tightening bolts etc. I'll give that a shot especially with the case covers to see if that helps them hold up a bit more while doing the bolts up.

Leave a comment:

-

fwiw, I repainted my engine with the vht and i am SURE my prep was not as good as yours and it is holding up well 3 years in... Only issues I had were with the paint chipping when bolts got tightened up.... Always good to see progress on this project, looking good!!

Leave a comment:

-

I'm not too stressed on it Greg, got plenty of mates with hotted up Kats that still run the stock auto tensioner with no problems.

I've got new seals ready to rebuild it and will give it the proper tension and locktite treatment so it should be good to rock and roll.

Leave a comment:

-

Toss that factory tensioner. Get a manual tensioner.

Or conversely, I saw somewhere, a modified factory one that functioned as a manual tensioner.

Leave a comment:

-

Finally! Perfect painting weather today, so the cylinders, crankcase covers, and camchain tensioner are at last painted.

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

I have a nagging feeling my prep on the cylinders wasn't as good as on the crankcases but I guess we'll see how the paint holds up.

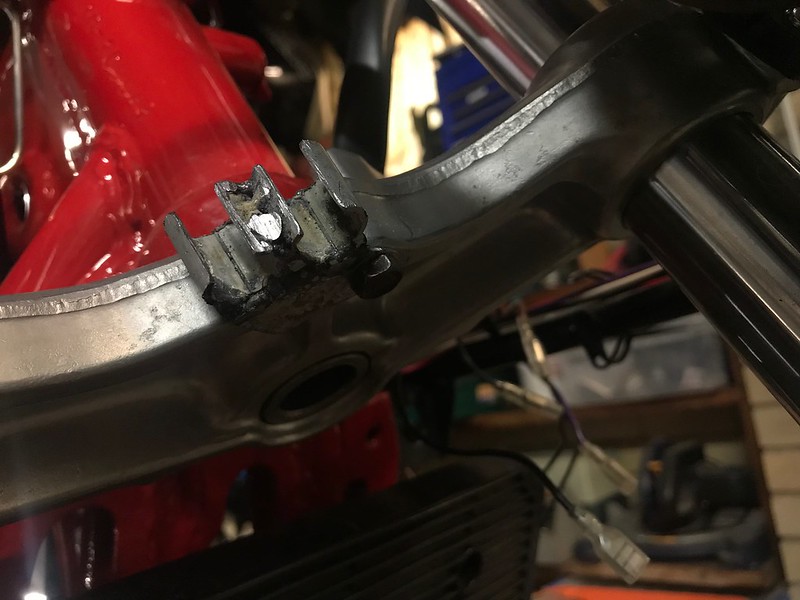

I also made a bracket to secure the brake lines against the lower triple clamp.

I have some steel tube with an inside diameter spot on for the rubber grommets on the loaned brake lines, so I simply cut two lengths of that and welded them to a 1.5mm thick bit of steel bent to shape.

I need to file the openings a bit wider yet for the grommets and lines to squeeze in but should do the trick nicely. It'll get some satin black at some point.

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Might see if I can get the crankcase off the engine mount and up the right way next weekend so I can start some assembly.

Leave a comment:

-

Cheers Larry, will feel good to get it done at last! And yep two weekends in a row of rain and as a result the weekend just gone was very humid. Started to dry out and get nice and sunny today and the forecast for this weekend is good so far, so fingers crossed! I do need to get out there between now and then to finish the masking and give everything a good clean with wax and grease remover too.

Leave a comment:

-

Always good to see progress, Pete. Is the weather too humid to paint the engine?

Leave a comment:

-

Still not much to report, weather still wasn't good for painting today but at least I should be prepared for next weekend. I broke out the grey scotchbrite pad and gave the bits a rub down and got them hung up and laid out ready.

I still have some masking to do for the cylinders yet, and everything will need a good go over with wax and grease remover also.

The weather prediction looks a little more promising for next weekend too.

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

I also mocked up a loaned set of braided brake lines for the front to figure out the banjo angles and lengths of both lines. I needed to make sure all sat well with the location of the GSX-R750 master and front cowl.

Clearance is good by the looks at full lock. Left lock does have the left line nudging the front cowl support bracket but it's just a nudge so no issues there.

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

I'll probably try to find a better way to locate the lines against the bottom triple clamp but the cable clamp worked for the mock up.

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

I used masking tape to mark where the end of the banjo bolts will be as that's the measurement the guy at HEL uses to make the lines.

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Looks like I know what I need now... 20 degree angle on the master end of the banjo fittings and a 765mm and 775mm line plus the rear line, should be able to grab those next pay.

I'm also going DOT 5 fluid so I can at least get the brakes built soon and get at least a little satisfaction while I play the waiting game to build some more funds back up for the rest.

Leave a comment:

-

Unfortunately not Sam, no sooner was I ready to paint than the weather turned against me and the last couple of weekends have been very wet.

I'll have to revisit the prep work this weekend now given they've been sitting, hopefully get paint done the following weekend.

Leave a comment:

-

Picked up some paint stripper on Friday and set it to work today.

Forgot to get some brake cleaner though so even though all these bits are now stripped and have had a good start on sanding, there'll be more paint prep required so next weekend will be more of the same rather than painting, fingers crossed for the week after to get the paint done.

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Also picked up the base, head, and valve cover gaskets on Friday, and while the paint stripper went to work I grabbed out all the bits I've got ready for the top end assembly.

Started comparing bits with fiches and looks like I've missed a couple of things I think, need to go through a bit more thorougly and order what's missing.

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

One concern I had was comparing the base gasket to the bottom of the barrels, and I thought there was an issue due to the shape and having extra holes in the cylinders beside where the studs go through. After much Googling and looking closer at fiches it looks like everything is ok, but anyone care to confirm it looks right?

Untitled by starpoint73, on Flickr

Untitled by starpoint73, on Flickr

Leave a comment:

-

I didn't check the clearance like that no, but I did measure the bores and they were all in spec. I haven't measured afterwards though as they're borrowed tools which I've returned. I don't think I wrote the initial measurements down anywhere either...

Leave a comment:

-

Pete did you take readings before honing of the clearance between the piston and cylinder wall? If so, did you also check clearances after the honing? I'm just curious as to how much the honing actually takes off.

Leave a comment:

-

Cheers Daryl, yeah that's as slow as my drill will go, just barely got the trigger to where it will start spinning. I "know" the 45 degree crosshatch is the goal but I was having great difficulty working out how fast to stroke. I'm not sure how keen I am to have another crack at it in case I start taking too much material out... don't want to take the bores out of spec!

And cheers Glen, a mate has an after market catch tank where his sprocket cover is and I thought the idea was great but wanted it to be more part of the motor, so hopefully it fits in well once it's painted up and installed.

Leave a comment:

.png)

Leave a comment: