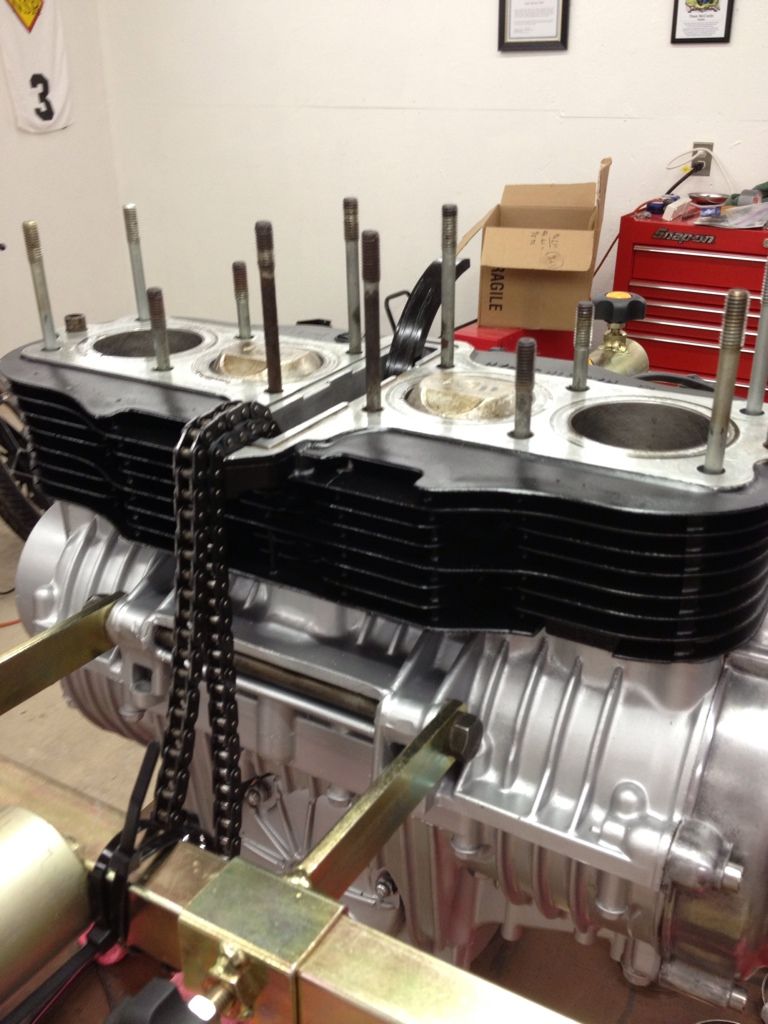

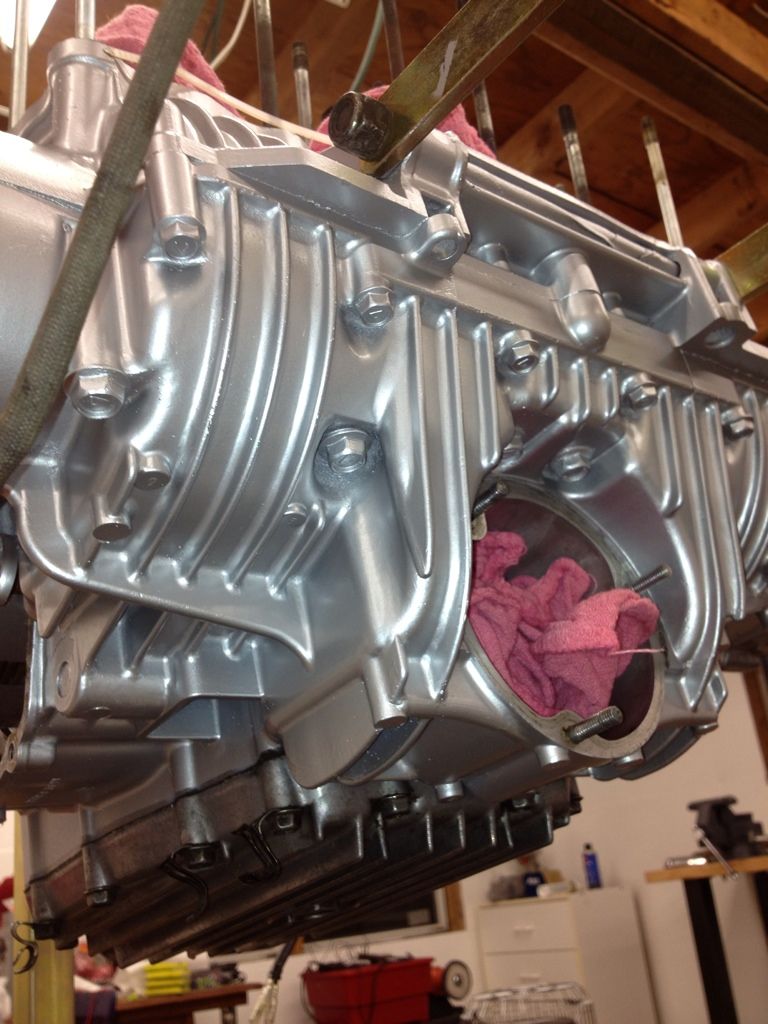

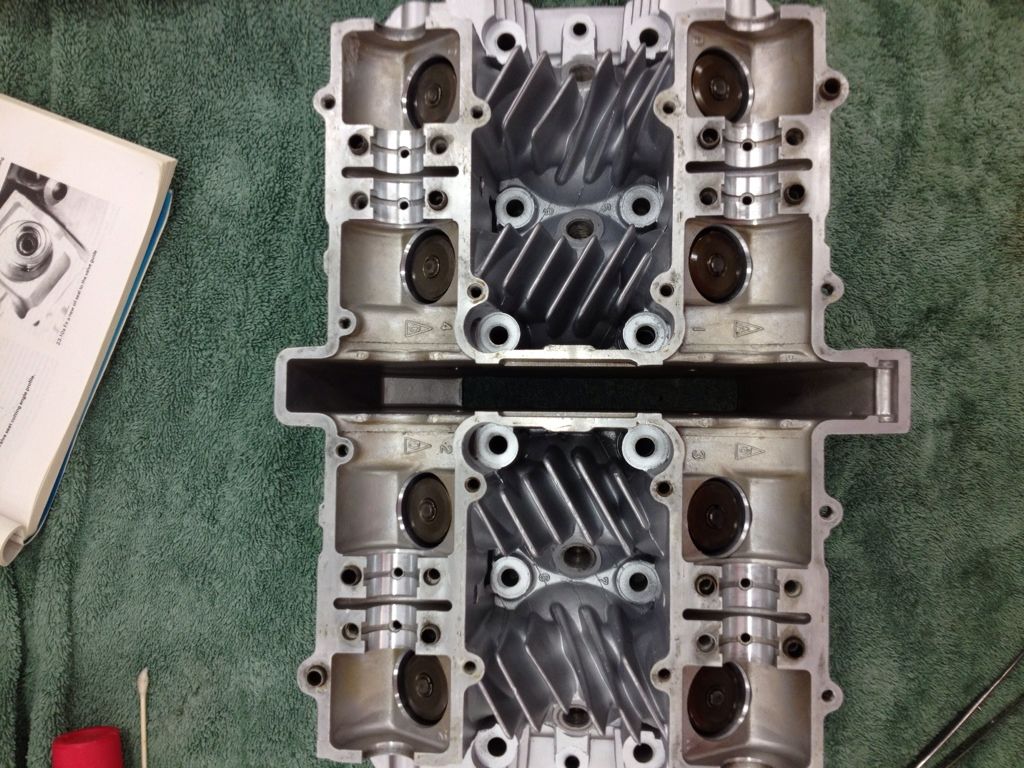

As I mentioned the other day, I ended up removing and replacing the cylinders to get the guide pins in, so next up was the head, which was now ready FINALLY and not leaking. The only other thing I did was knock down a fine edge on one part with a jewlers? file (I?m sure it didn?t matter much, but I didn?t want a fine burr on an outside edge to prevent a proper seal on the head gasket).

It took a little juggling to get the cam chain up through the head without any help. I went with a Suzuki head gasket and o-ring, even though they are fairly pricey. Then I torqued the various fasteners in the designated order in 4 steps. I used all new fasteners because the old ones were a little beat and rusty.

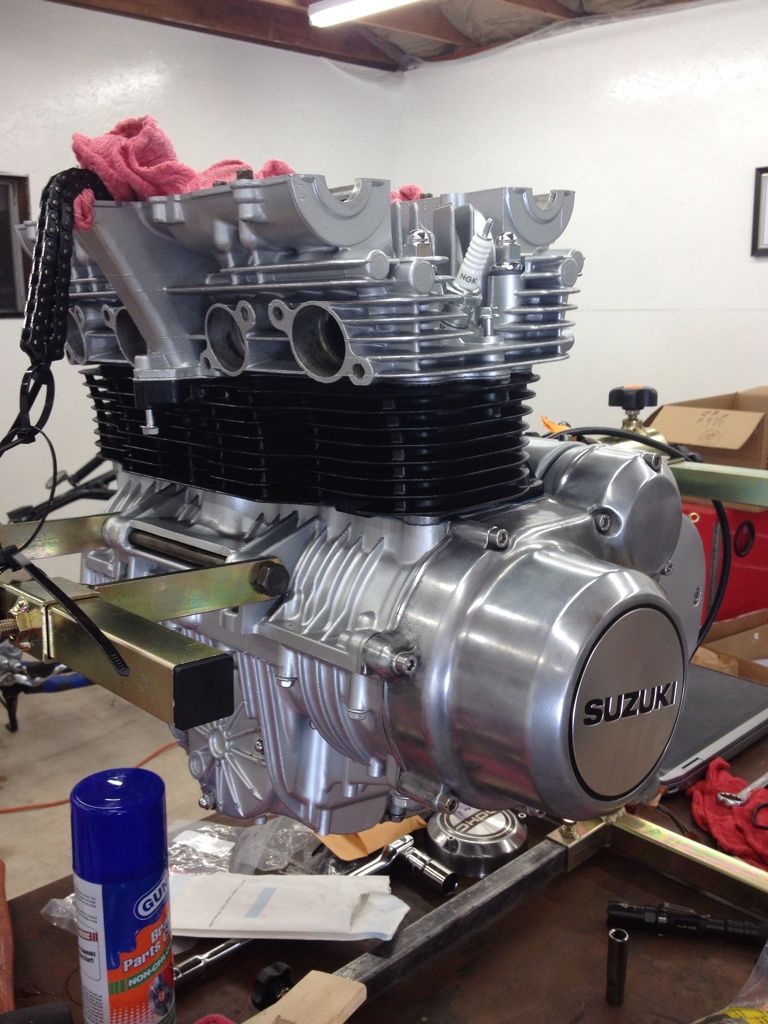

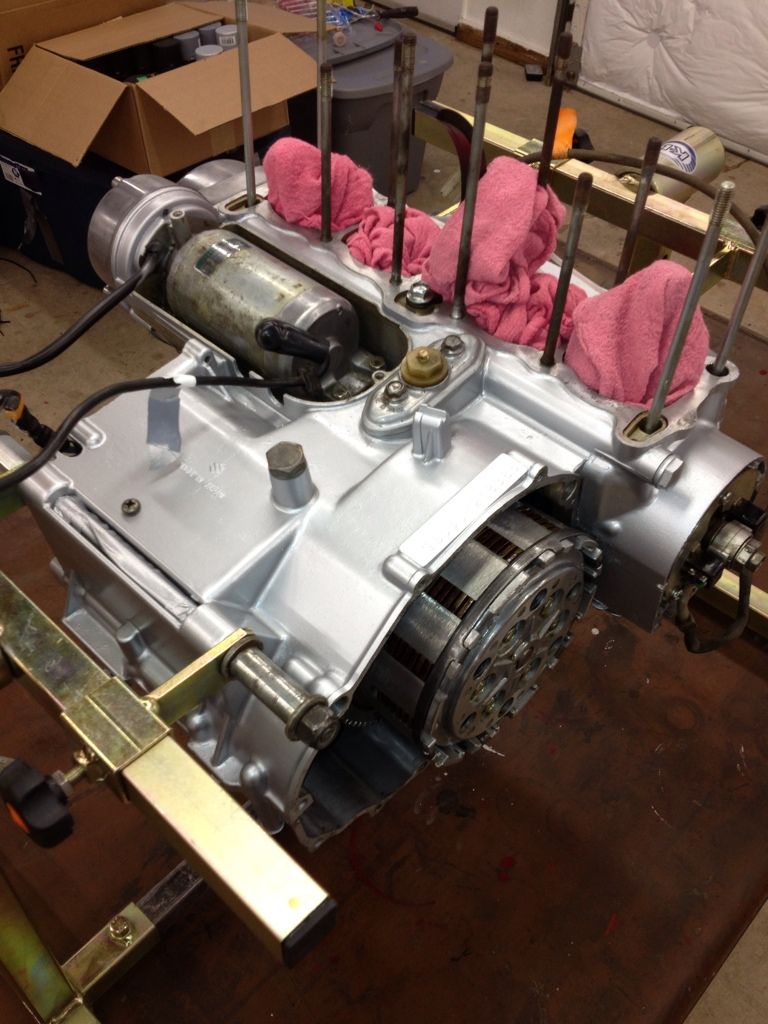

Pretty. Note that I hadn?t tightened some of the fasteners down when I took this photo (like the bolt on the front of the head/cylinder).

Now to tackle valve lash/cam chain tensioner, timing, etc. This will take a while.

It goes around one of the studs, so the "easiest" thing to do was to pull off the cylinders, install the pin, and replace the cylinders again. It was easier the second time, although I still had to get one kid and my wife to help out.

It goes around one of the studs, so the "easiest" thing to do was to pull off the cylinders, install the pin, and replace the cylinders again. It was easier the second time, although I still had to get one kid and my wife to help out.

Leave a comment: