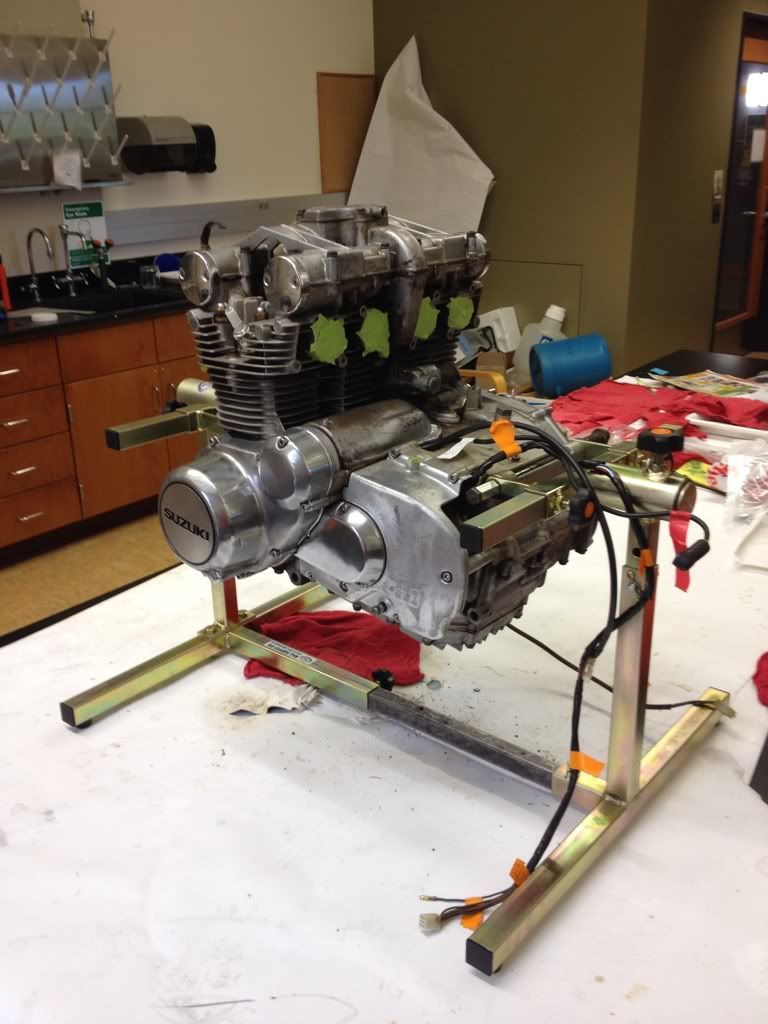

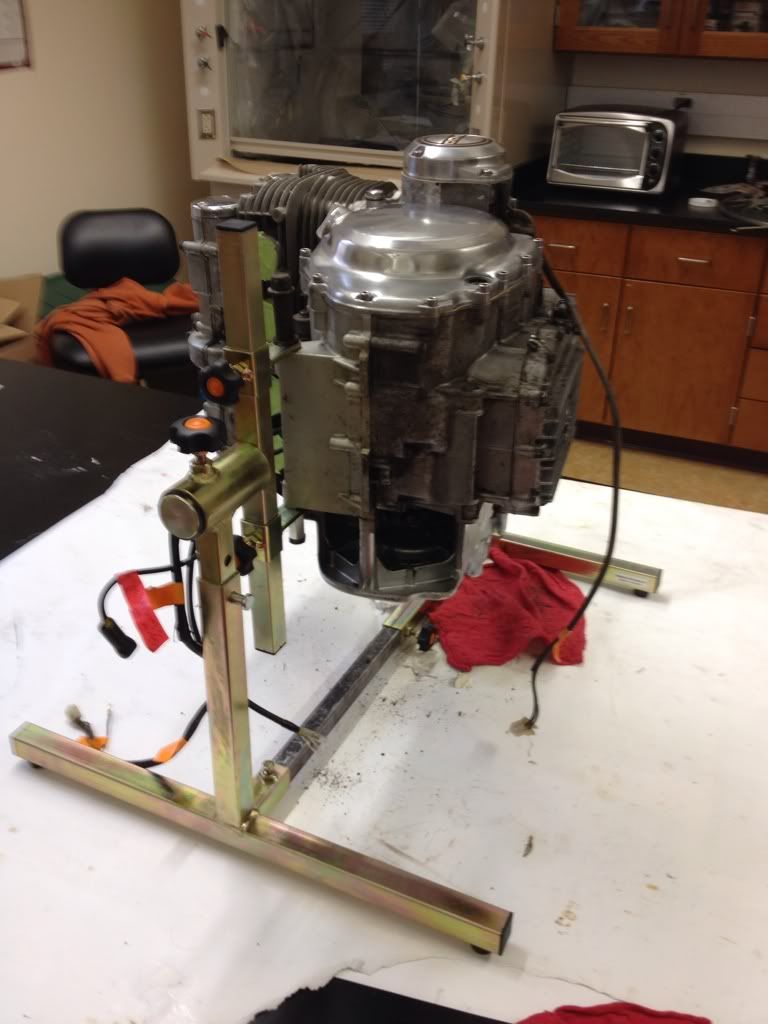

Over the summer I moved. Beginning in mid-June, I had to store my tools and bike in storage while I staged my old house and moved into the new one. Everything got delayed for a month longer than planned, but I'm FINALLY moving in to the the new place now. I also took a machining course and another motorcycle class over the summer to keep my skills sharp. I spent about a month COMPLETELY disassembling, blueprinting, fixing, and reassembling a 2001 GSXR-1000 as part of one class. A GS is soooo simple compared to that thing! In the end, it ran like a top on the dyno, so I have more confidence that I can get my little GS running well this fall/winter.

My new house has a 1200 square foot detached garage, which will be dedicated to motorcycle repair (there is also a 2-car garage attached to the house, which my wife gets for her stuff

). Inside there is a large 500 sqft room, which I have been busy insulating, wiring, and cleaning for a shop space. In another week or so I should be done with the drywall, lighting, and cleaning, and I will FINALLY start working on the 550 again! Once I order rings, I will be ready to install the pistons, put the valves back in, and reassemble the top-end. Then I just need to paint the bottom end, do the wiring, and reassemble the whole bike!

). Inside there is a large 500 sqft room, which I have been busy insulating, wiring, and cleaning for a shop space. In another week or so I should be done with the drywall, lighting, and cleaning, and I will FINALLY start working on the 550 again! Once I order rings, I will be ready to install the pistons, put the valves back in, and reassemble the top-end. Then I just need to paint the bottom end, do the wiring, and reassemble the whole bike!I did manage to make some progress in June/July. Specifically, I cleaned up the valves and valve seats, re-honed the cylinders, and learned how to use all of the machined involved. I will post pics and a tutorial later this week. I also picked up some key tools for this project and future projects (e.g., wheel stand, vacuum gauge, more reliable compression tester, valve spring compression tool, etc.)

I'm really looking forward to diving back into the GS! Stay tuned.

Leave a comment: